Rolls-Royce Silver Shadow

6

Bentley

T

Series

Workshop

Manual

I. Thoroughly clean all components before assem-

Half-shaft-T~

fit

bly.

2.

When assembling the Hardy Spicer universal

joint onto the half-shaft, the needle roller bearings

should

be

fitted in the retainers and smeared with

Retinax A grease (see under 'Hardy Spicer joint-

To fit').

Note It is important not to pack too much

grease on the rollers or in the retainers

as this could result in damage to the lip

seals on assembly.

3.

Assemble the trunnion bearings, and buttons

onto the trunnion pin, but at this stage do not fit the

adjusting washers under the trunnion button heads.

4.

Using a micrometer, carefully measure the

dimension over the trunnion buttons.

5. Measure the dimension between the outer cir-

cumferences of the two outer bores in the joint

housing in which the buttons locate.

6.

The difference between these two dimensions

gives the amount which must

be

taken up by adjust-

ment, but it is

essential

that this figure is divided by

two and washers of equal thickness fitted under each

button.

7.

The adjustment should

be

carried out by fitting

shim

washers under the trunnion buttons to obtain

a

fit of 0.0005 in. (0,013

mm.)

tight to 0.0005

in.

(0,013

mm.)

slack

in

the joint housing.

Shim

washers are available for this purpose in a

8

range from 0.012 in. to 0.023 in. (0,304

rnm.

to 0,584

#

mm.)

in 0.001 in. (0,025

mm.)

increments.

8.

Fit the correctly adjusted trunnion assembly into

the joint body then ease the neoprene seal over the

body and tighten the two seal clips, ensuring that the

small end of the seal is located correctly on to the

machined diameter of the half-shaft.

Note When the half-shaft has been fitted to

the car the seal should be inspected, whilst

the car is at its normal standing height,

to ensure that the seal convolutions are

not 'crimped' or strained. If they are,

the position of the seal on the half-shaft

should be adjusted slightly to correct this.

9.

Remove the drain plug from the joint housing

m

and inject 150

C.C.

of

S.A.E.

90

EP

oil into the joint

and refit the plug.

10.

Fit the half-shaft as instructed under 'Half-shaft

6

-To

fit'.

Fit the half-shaft by reversing the procedure given

for removal, noting the following points.

1.

If

an exchange shaft is being fitted, this is supplied

suitably blanked and protected.

Remove the pro-

tective covering from the joint body splines and also

remove the cover on the breather hole in the end of

the

splined shaft.

All

traces of protective material

must

be

removed.

2.

Remove the drain plug from the joint body and

inject 150

C.C.

of S.A.E. 90

EP

oil into the joint;

fit

the plug.

3.

Remove the circlip and washer from behind the

bearing housing on the old shaft and fit the housing,

washer and

circlip to the new shaft.

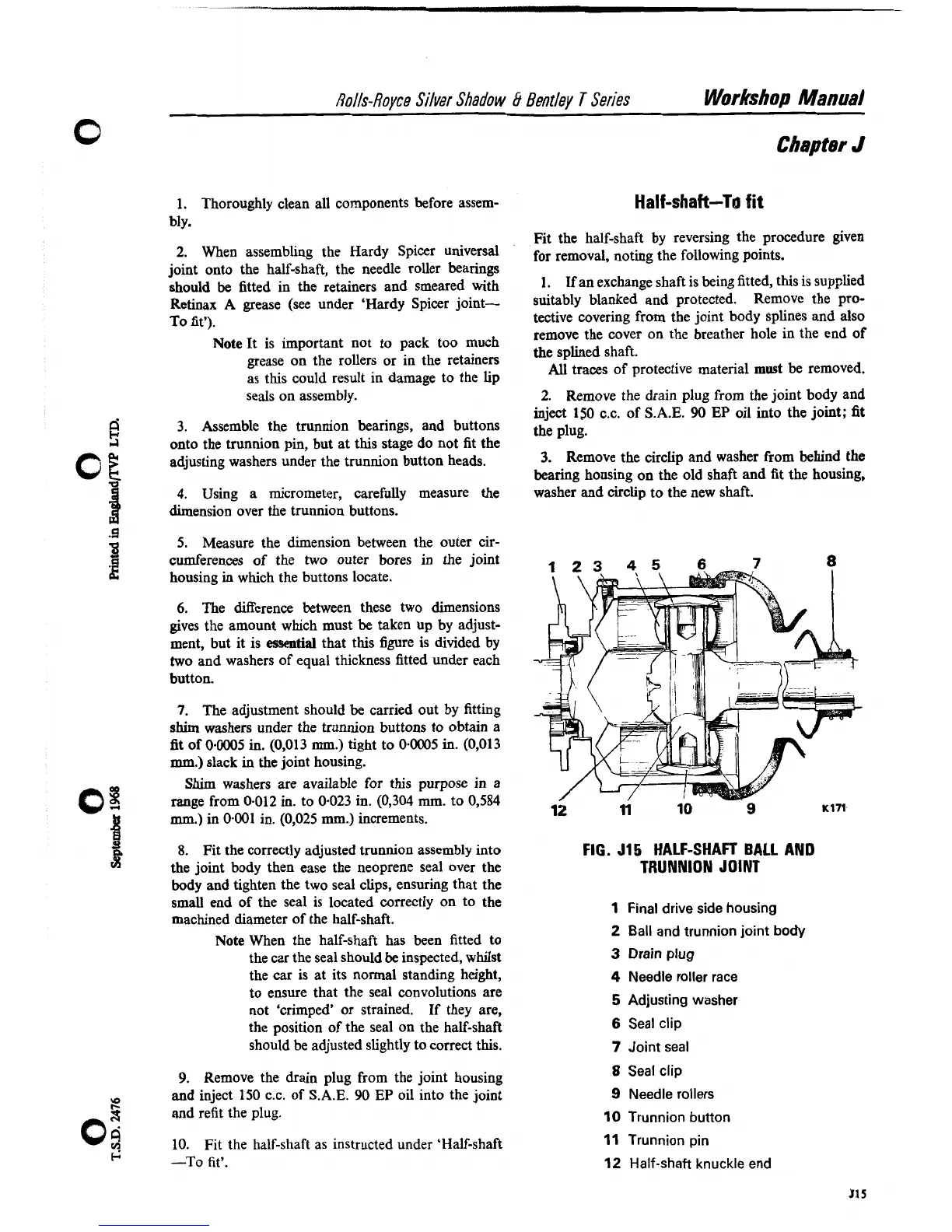

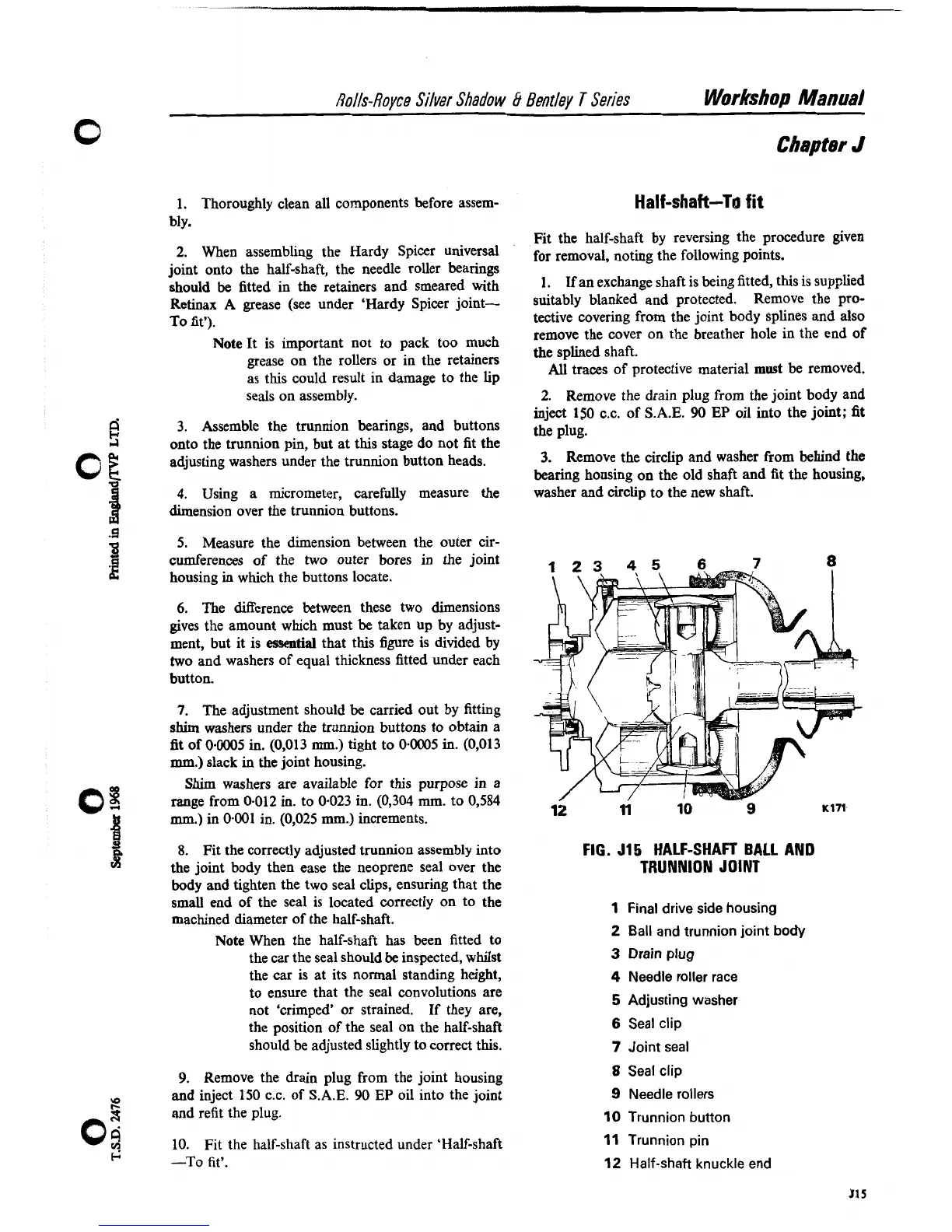

FIG. 515

HALF-SHAFT BALL AND

TRUNNION JOINT

1

Final drive side housing

2

Ball and trunnion joint body

3

Drain plug

4

Needle roller race

5

Adjusting washer

6

Seal clip

7

Joint seal

8

Seal clip

9

Needle rollers

10

Trunnion button

11

Trunnion pin

12

Half-shaft knuckle end

Loading...

Loading...