lolls-lo~re Silver Shadow

B

Bentlev

T

Series

Worksho~

Manual

thoroughly. Inspect the diaphragm assembly and nylon

armature guide plate for damage or deterioration;

renew if necessary.

8. Before assembling the pump release the spring

blade retaining screw in the contact breaker sufficiently

to ensure that pressure is not applied to the tungsten

points and outer rocker. If pressure is applied at this

point during assembly, the correct setting of the

diaphragm cannot be obtained.

Solenoid housing and diaphragm-To fit

1.

When assembling the pump all cork and fibre

washers, gaskets and rubber

'0'

rings should

be

renewed.

2.

Place the armature spring in the solenoid housing

with the large diameter toward the solenoid.

3.

Before fitting the diaphragm, ensure that the

impact washer is fitted to the armature. This is a small

neoprene washer which fits into the armature recess.

4.

Fit the diaphragm by inserting the spindle into

the hole in the solenoid and screwing it into the

threaded trunnion in the centre of the rocker assembly.

5.

Screw in the diaphragm until the rocker will not

'toggle over'. This must not be confused with 'jamming'

the armature on the solenoid housing internal steps.

6.

On

fuel

pumps fitted

with

brass centralising

rollers, fit the eleven rollers by turning back the edge of

the diaphragm and dropping the rollers into the

solenoid recess. The pump should be held rocker end

downwards to prevent the rollers from falling out.

7.

Fit the contact blade and adjust the finger settings

by inserting a feeler gauge between the rocker finger

and solenoid housing. If necessary, bend the stop finger

to obtain a gap of between 0.065 in. and

0.075 in.

(1,65

mm.

and 1,90 mm.). Carefully remove the contact

blade.

8.

Hold the solenoid housing assembly in an ap-

proximately horizontal position and firmly, but steadily

push in the diaphragm spindle. Unscrew the dia-

phragm, alternatively pressing and releasing, until the

rocker just 'toggles over'.

9.

To set the diaphragm, unscrew to the nearest

hole and then unscrew a further four holes (two-thirds

of a complete turn). The diaphragm is now correctly

set.

10. On

fuel: pumps fitted

with

brass centralising

rollers, press the centre of the armature and fit the

retaining fork at the back of the rocker assembly.

This is necessary to prevent the rollers from falling

out when the solenoid

housiilg is placed on the bench

prior to fitting the body. It is not

intendcd to stretch

the diaphragm before tightening the body screws.

For fuel pumps fitted

with

nylon armature guide plates

carry out Operations

11

to

13

inclusive.

Chapter

K

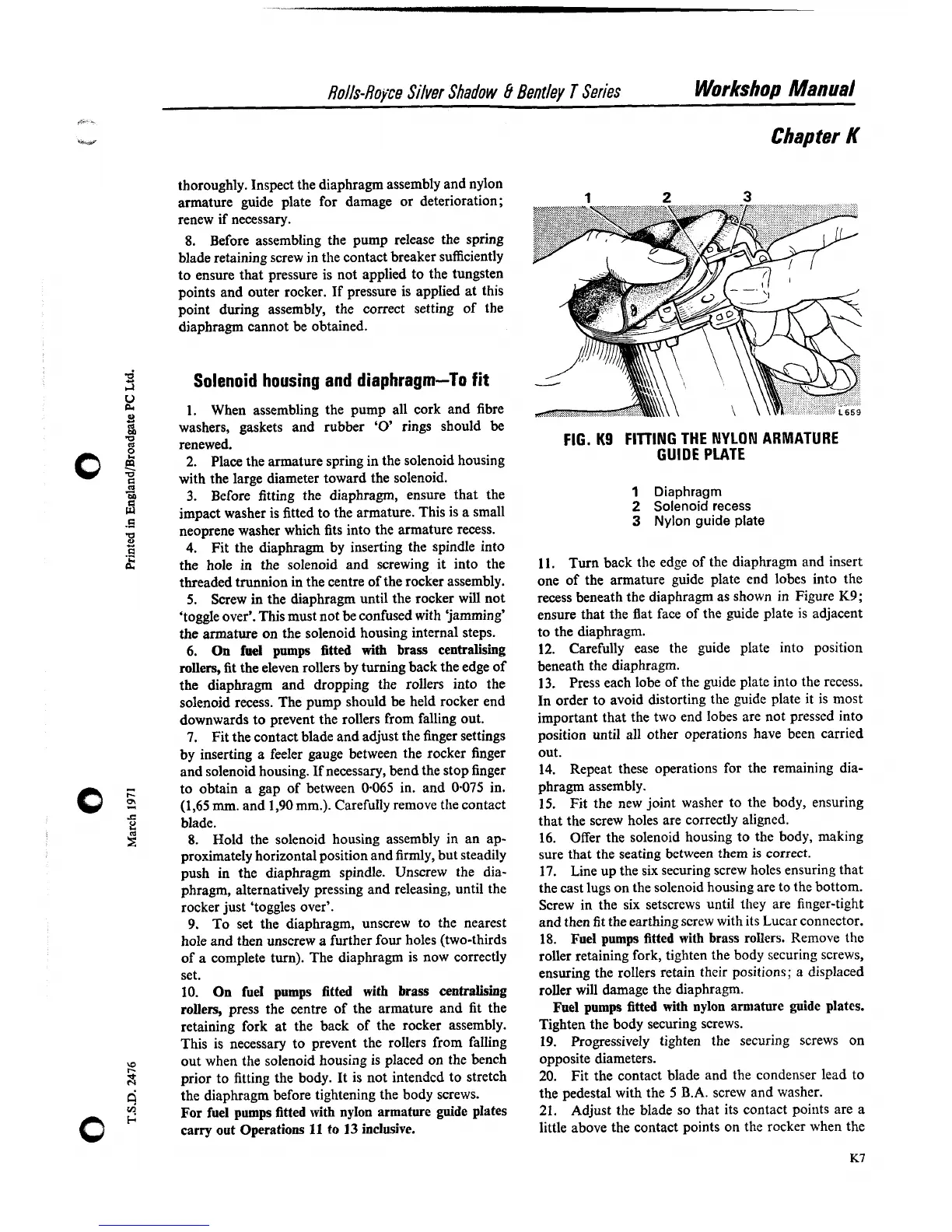

FIG.

K9

FITTING

THE NYLON

ARMATURE

GUIDE

PLATE

1

Diaphragm

2

Solenoid recess

3

Nylon

guide

plate

11. Turn back the edge of the diaphragm and insert

one of the armature guide plate end lobes into the

recess beneath the diaphragm as shown in Figure K9;

ensure that the flat face of the guide plate is adjacent

to the diaphragm.

12. Carefully ease the guide plate into position

beneath the diaphragm.

13. Press each lobe of the guide plate into the recess.

In order to avoid distorting the guide plate it is most

important that the two end lobes are not pressed into

position until all other operations have been carried

out.

14. Repeat these operations for the remaining dia-

phragm assembly.

15. Fit the new joint washer to the body, ensuring

that the screw holes are correctly aligned.

16. Offer the solenoid housing to the body, making

sure that the seating between

them

is

correct.

17.

Line up the six securing screw holes ensuring that

the cast lugs on the solenoid housing are to the bottom.

Screw in the six setscrews until they are finger-tight

and then fit the earthing screw with its Lucar connector.

18. Fuel pumps fitted with brass rollers. Remove

the

roller retaining fork, tighten the body securing screws,

ensuring the rollers retain their positions; a displaced

roller will damage the diaphragm.

Fuel pumps fitted with nylon

armature

guide

plates.

Tighten the body securing screws.

19. Progressively tighten the securing screws on

opposite diameters.

20. Fit the contact blade and the condenser lead to

the pedestal with the

5

B.A.

screw and washer.

21.

Adjust the blade so that its contact points are a

little above the contact points on the rocker when the

Loading...

Loading...