EN

45

6.3 Further information

Want to adjust, replace or service components yourself and according to your own requirements? If you are certain that

you have sufficient knowledge and skills for it, you will find all necessary information about these tasks on the respective

manufacturer’s website. Please bear in mind that you take responsibility for all jobs carried out by yourself.

At https://www.rosebikes.com/manuals, "Frame Details" are available for each bike model. Here you will find all spare

parts, torque values and other specific details for your bike.

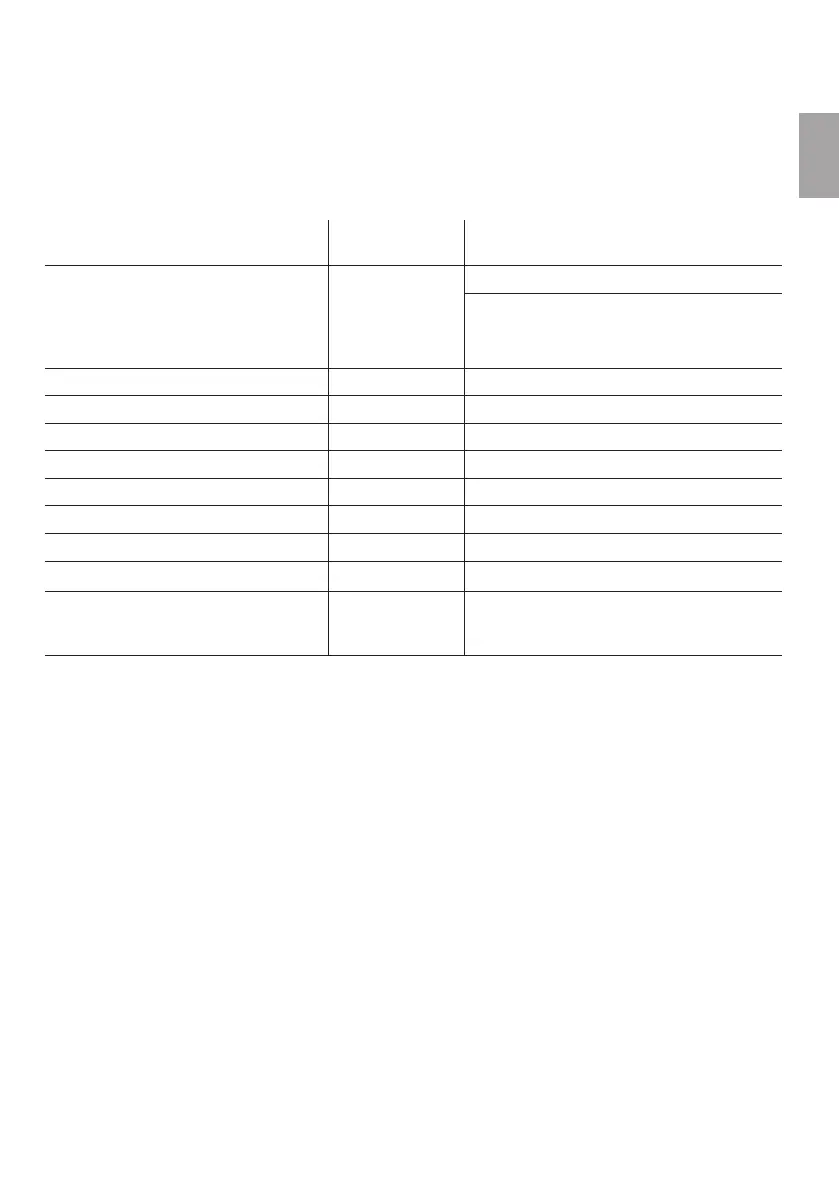

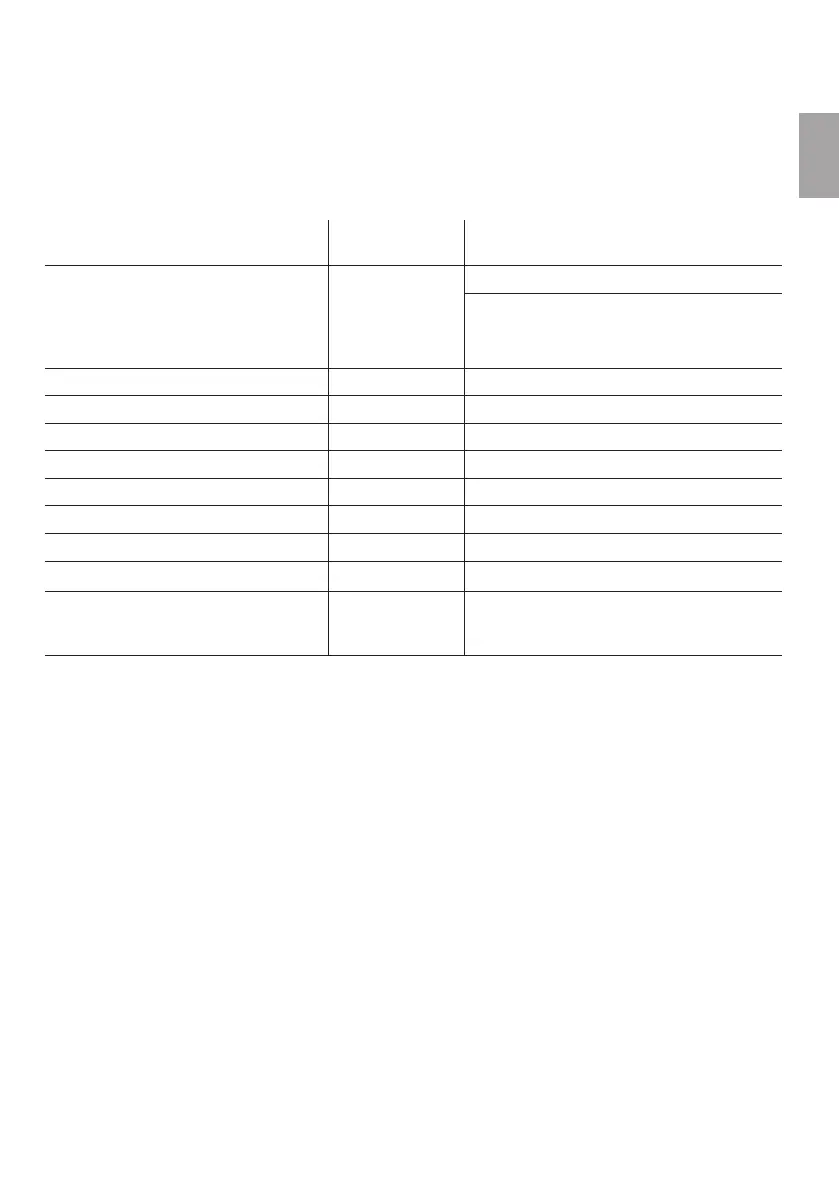

6.4 Torques for components

All nuts and bolts must be tightened with an appropriate torque wrench. Proper use prevents overtightening and breaking

of the bolts.

Components Manufacturer,

Model

Torque

Reverse Black One

Steerer clamp: 5 - 6Nm

Handlebar clamp:

• upper clamp bolts 6 Nm

• lower clamp bolts 1 Nm

Saddle clamp all 6 Nm

Brake calliper mounting, rear wheel all 6 Nm

Front axle all See manufacturer’s instructions

Rear axle all See manufacturer’s instructions

Brake rotor bolts all

6.2 Nm

Crank bolt

all

See torque value lasered on

Bottom bracket

BSA

40Nm

Pedals all

35 Nm

Operating elements at the handlebar all

See torque value lasered on*

Pay attention to additional instructions from the

handlebar manufacturer!

*The torque value must not be exceeded. As a rule, a lower torque is sufficient for a secure hold. Especially when using

assembly paste, the necessary torque is often much lower, because the solid particles in the lubricant significantly

increase the friction.

Tip: The lower the torque value of the bolt, the less stress it puts on the component – this is especially important with

carbon components.

Loading...

Loading...