Servicing and cleaning

80 / 97

Service procedures

► Completely screw on oil drain hose and drain oil.

► Collect the old oil and dispose of it properly.

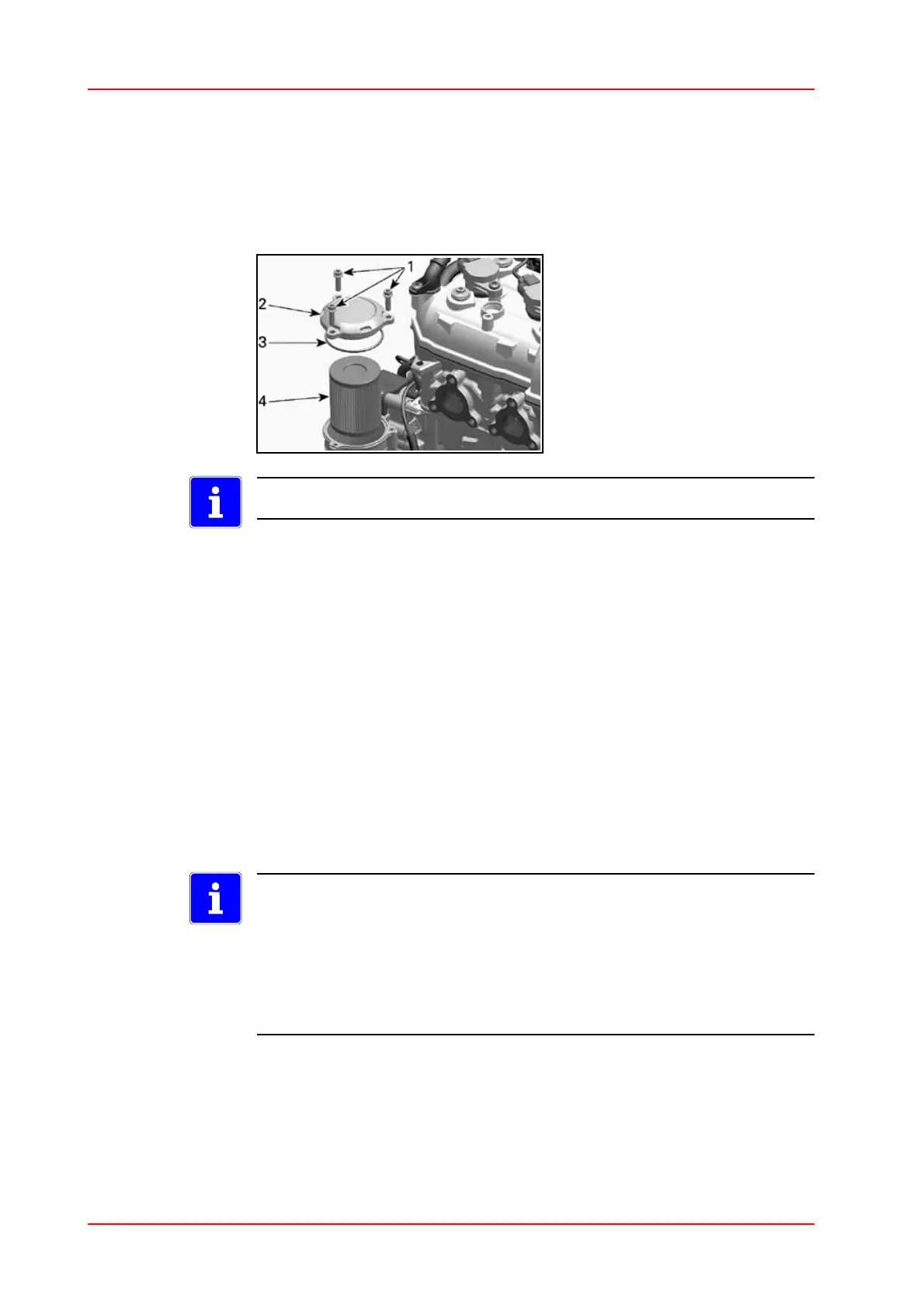

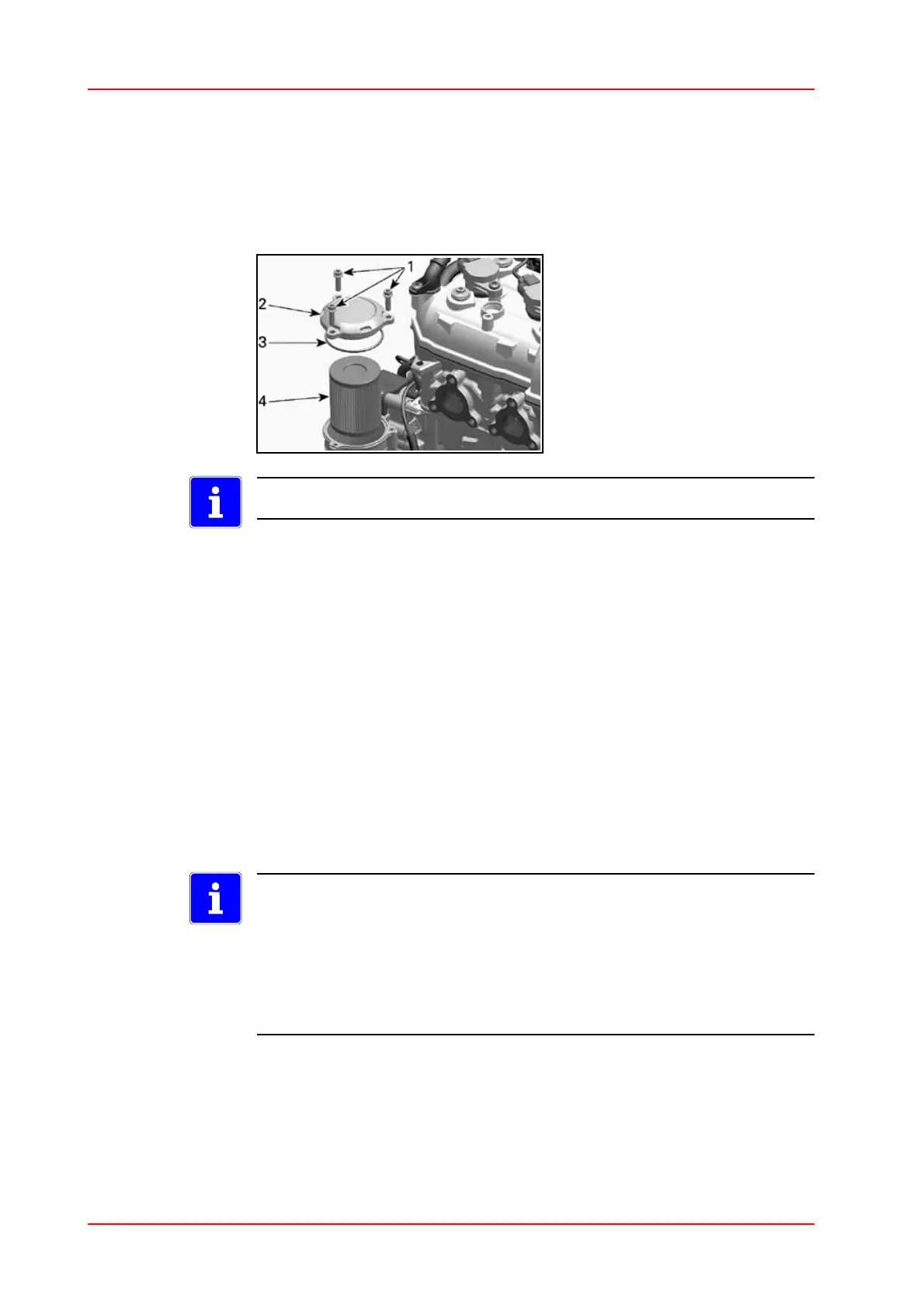

► After approx. 1.7l used oil has flowed out, the 3 fastening screws (1)

are opened on the oil filter housing (M11) and the oil filter (4) removed.

Oil is drained.

Observe the local regulations for oil disposal.

Top up oil

► Fit the new O-Ring (3) to the oil filter cover (2) and oil the O-Ring and

the sealing lip of the oil filter (4).

► Insert the oil filter (4) as depicted and fit the oil filter cover (2).

Tightening torque of the fastening screws 9 Nm.

► Unscrew sealing cap on oil drain valve (M23).

► Add oil into the oil dipstick opening (M2) using a suitable funnel and

wait until it has run down. Then reinsert the oil dipstick (M2).

Oil quality and oil filling quantity, refer to chapter "Lubrication

chart".

► For approx. 20 secs. put portable fire pump in operation idling.

► Check that the oil level is between the MIN and MAX markings.

► If the oil level is too low, add oil.

Oil has been changed.

Reduced performance or failure of the power transmission because of oil

on the v-belt.

Oil contaminated V-belts or V-belt pulleys can not transmit the required driv-

ing force and slip through.

Avoid oil pollution of the V-belts and V-belt pulleys.

Clean V-belts and V-belt pulleys contaminated with oil.

Loading...

Loading...