A4US

US

A4

US A4

US

A4

A4 US

US

A4

US

A4

A4 US

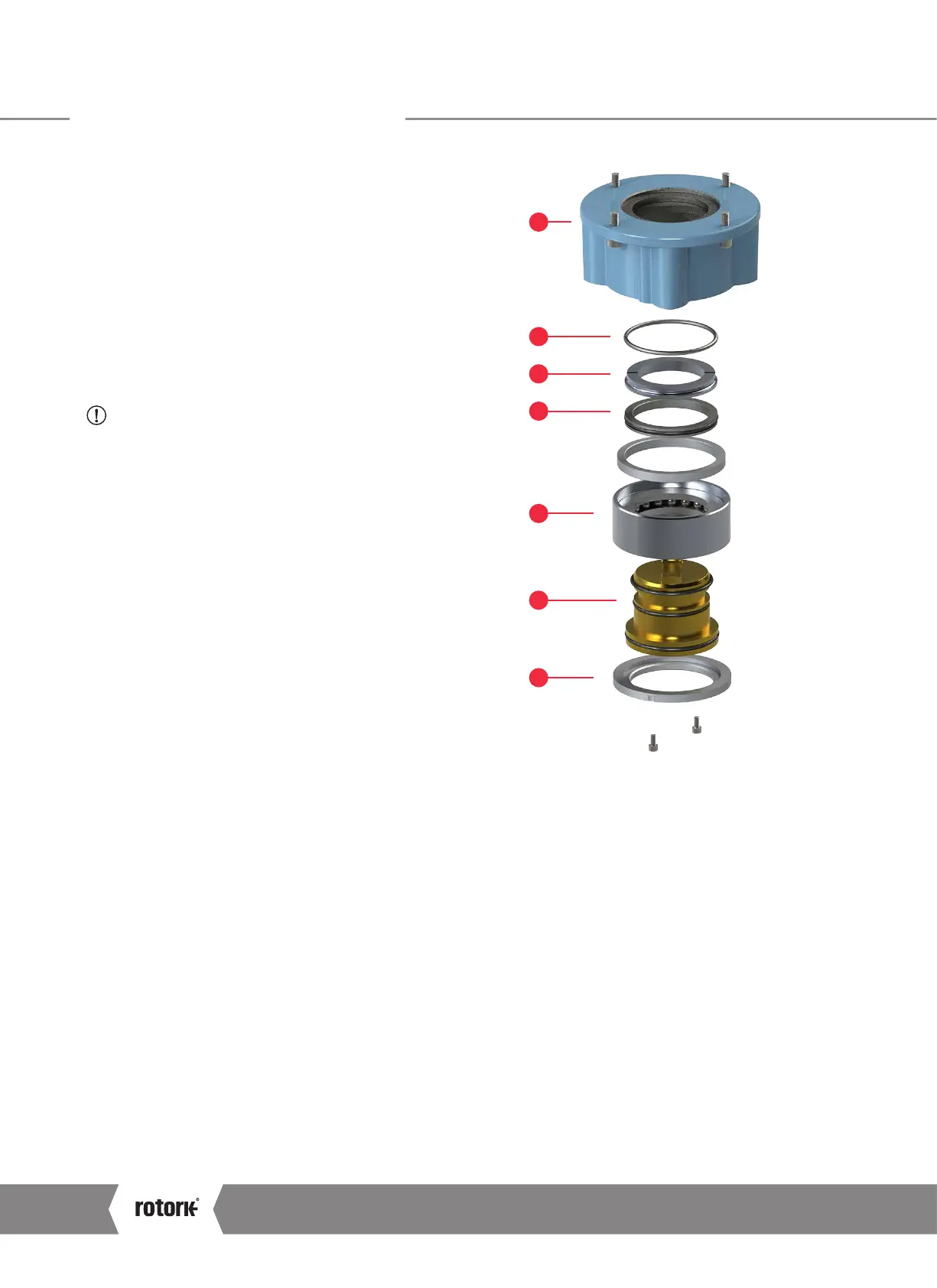

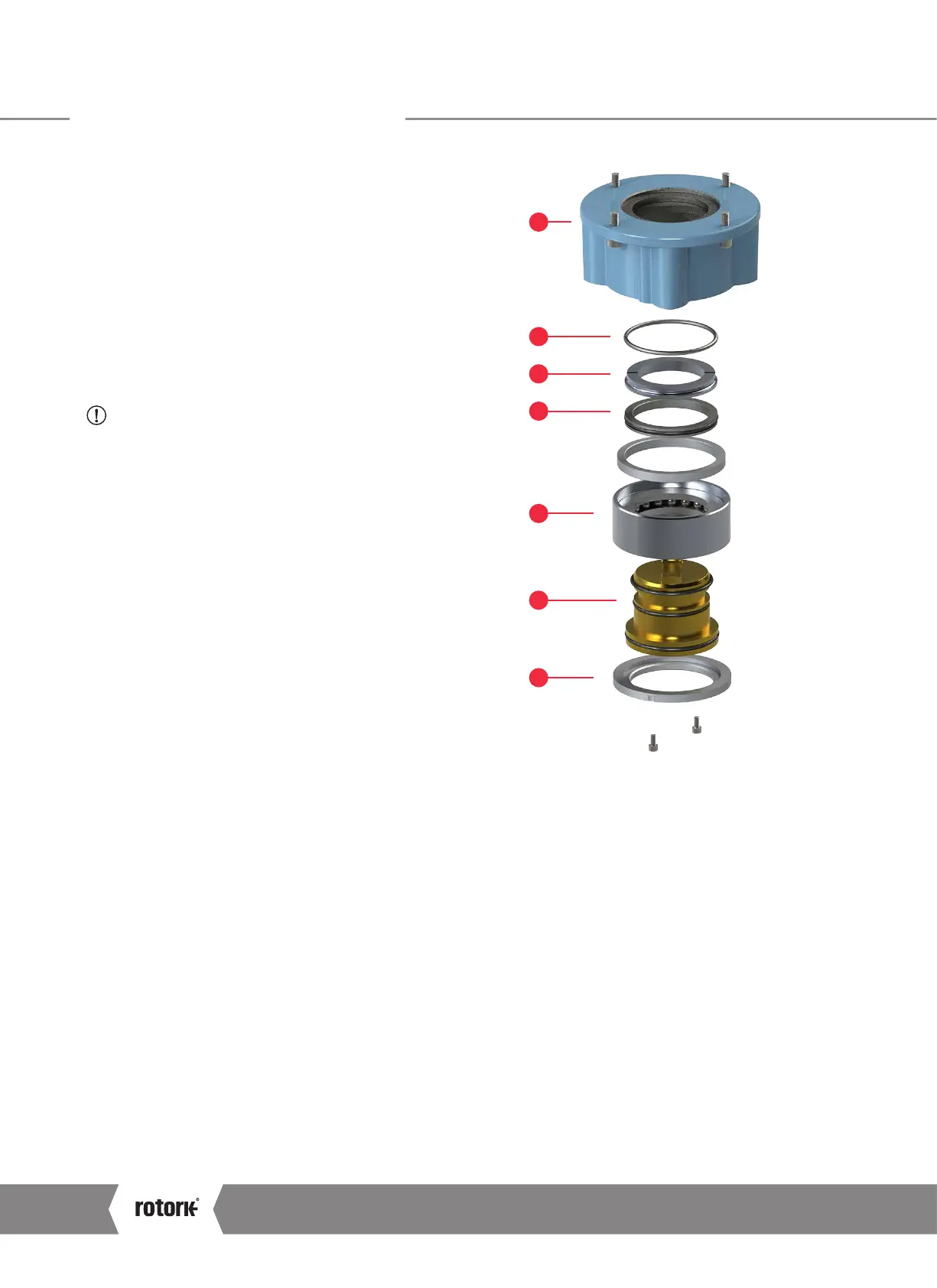

5 Preparing the Drive Bush

5.1 Drive Bush - Type A Coupling:

Please see Publication PUB111-001 for thrust/torque

allowances.

(Note: CK30/60 actuators may be fitted with a F07/FA07

flange adaptor, in which case this will need to be removed

before the below procedure is carried out).

Turn the actuator onto its side, removing the hex head screws

holding the thrust base (1) onto the actuator.

Remove the two M3 cap screws retaining the spigot ring (2)

Pull out the drive bush (3) complete with the bearing

assembly (4)

CAUTION: Failure to remove the bearing assembly

and the o-rings prior to machining may result in damage

to the bearing.

5.1.1 Disassembly of bearing assembly

Locate and remove the snap ring (5) using a suitable tool

Remove the split collar (6)

If fitted, remove the spacer ring (7)

Slide the bearing (4) off the drive bush (3)

Keep the bearing and the drive bush components clean.

The split collar keys (6) must be kept as a machined pair.

Machine the drive bush, after removing the o-rings, allowing

clearance for rising spindle applications.

5.1.2 Reassembly of bearing assembly

Ensure the drive bush (3) is clean and free from swarf. Ensure

the o-rings are clean and greased (see Section 11 for typical

grease). Slide the bearing assembly (4) onto the drive bush (3)

and ensure that it is fitted down to the shoulder. Grease and

refit the split collar keys (6) and spacer ring (7) if fitted and

secure with the snap ring (5).

Grease and refit the drive bush bearing assembly into the

thrust base.

Refit the thrust base (1) ensuring that the drive dogs on the

bush align with the slots in the hollow center column and

secure with the hex head screws to the following torque

values: See Table A on page 13.

1

5

6

7

4

2

3

CK Range Safe Use and Installation Manual

10

Loading...

Loading...