A4US

US

A4

US A4

US

A4

A4 US

US

A4

US

A4

A4 US

A4US

US

A4

US A4

US

A4

A4 US

US

A4

US

A4

A4 US

6 Mounting the Actuator

6.2 Mounting the Actuator -

Rising Stem Valves

6. 2.1 Fitting the actuator and base as a combined unit

- all sizes

Fit the machine drive bush as described in Section 5.1 into the

thrust base assembly.

Lower the actuator onto the thxreaded valve stem, engage

HAND operation and wind the handwheel in the open

direction to engage the drive bush onto the valve stem.

Continue winding the handwheel until the actuator is firmly

down on the valve flange. Continue winding for a further

two turns and secure with bolts, tightening down to the listed

torques - Table A.

6.2.2 Fitting thrust base to valve - all sizes

Fit the machine drive bush as described in Section 5.1 into the

thrust base assembly.

Remove the thrust base as described in Section 5.1 and place

it on the threaded valve spindle with the drive keys pointing

uppermost and turn the thrust base in the open direction to

engage it on the spindle. Continue turning until the thrust

base is on the valve flange but do not tighten at this stage.

Lower the actuator onto the thrust base and rotate the

complete actuator until the drive keys on the drive bush align

with the slots on the base of the center column. Continue to

turn the actuator until the fixings holes align with the thrust

base. Replace the base bolts and tighten to the required

torque - Table A.

Open the valve by two turns and secure the thrust base to the

valve flange and tighten to the required torque - Table A.

6.3 Mounting the Actuator -

Non Rising Stem Valves - Top Mounted

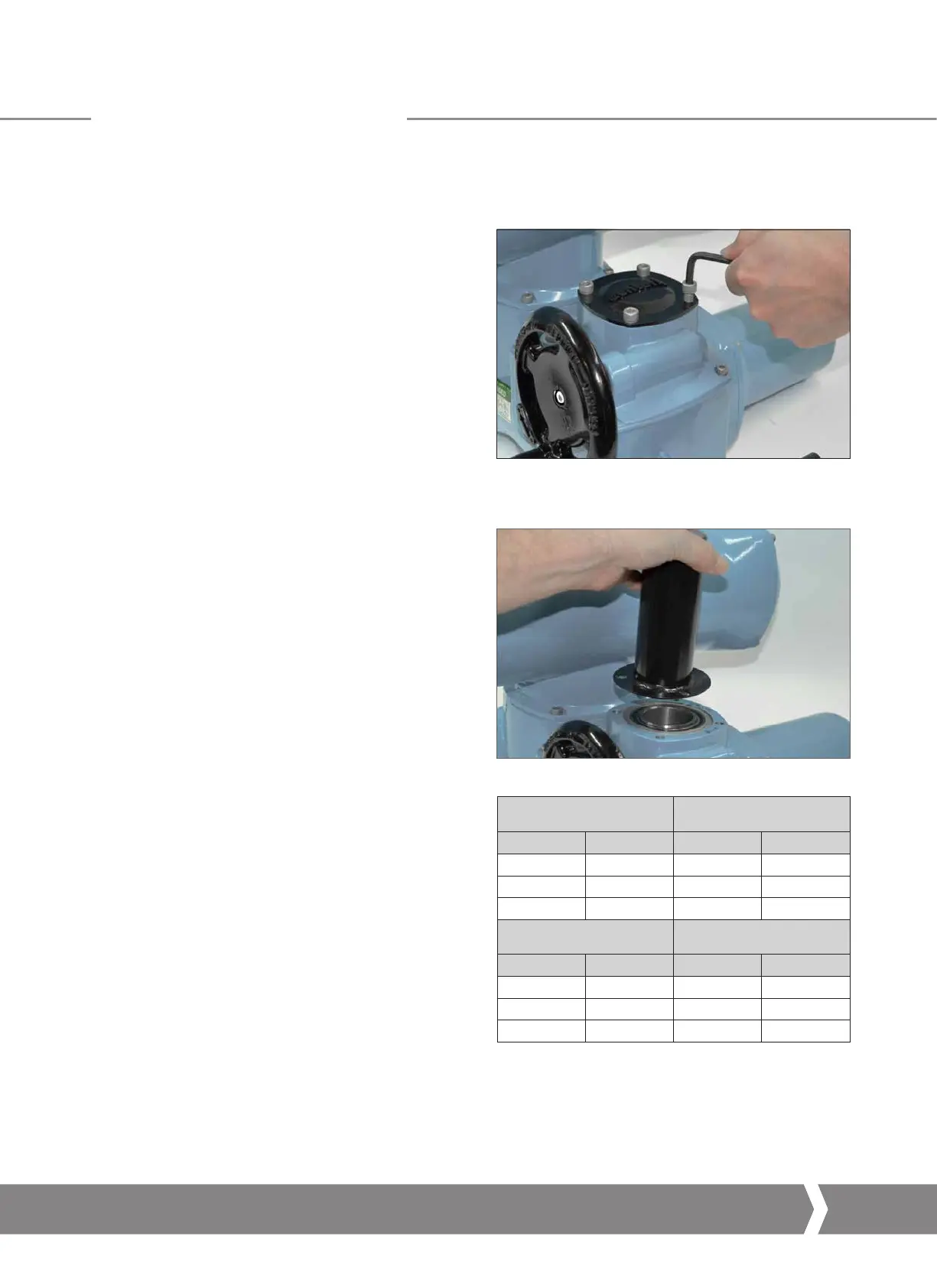

Ensuring that that the drive bush fits the input shaft/key and

has adequate axial engagement then fit into the actuator as

described in Section 5.1/5.2

Engage HAND, offer up the actuator to the valve, turning

the handwheel to align the drive bush. Tighten the mounting

bolts to the required torque - Table A.

Note: When the thrust is being taken in the actuator, a

thrust nut must be fitted above the drive bush and securely

tightened.

6.4 Mounting the Actuator -

Valve with Gearbox - Side Mounted

Follow the instructions in Section 6.3 as for top mounted

instructions, checking that the mounting flange is at right

angles to the shaft before installation.

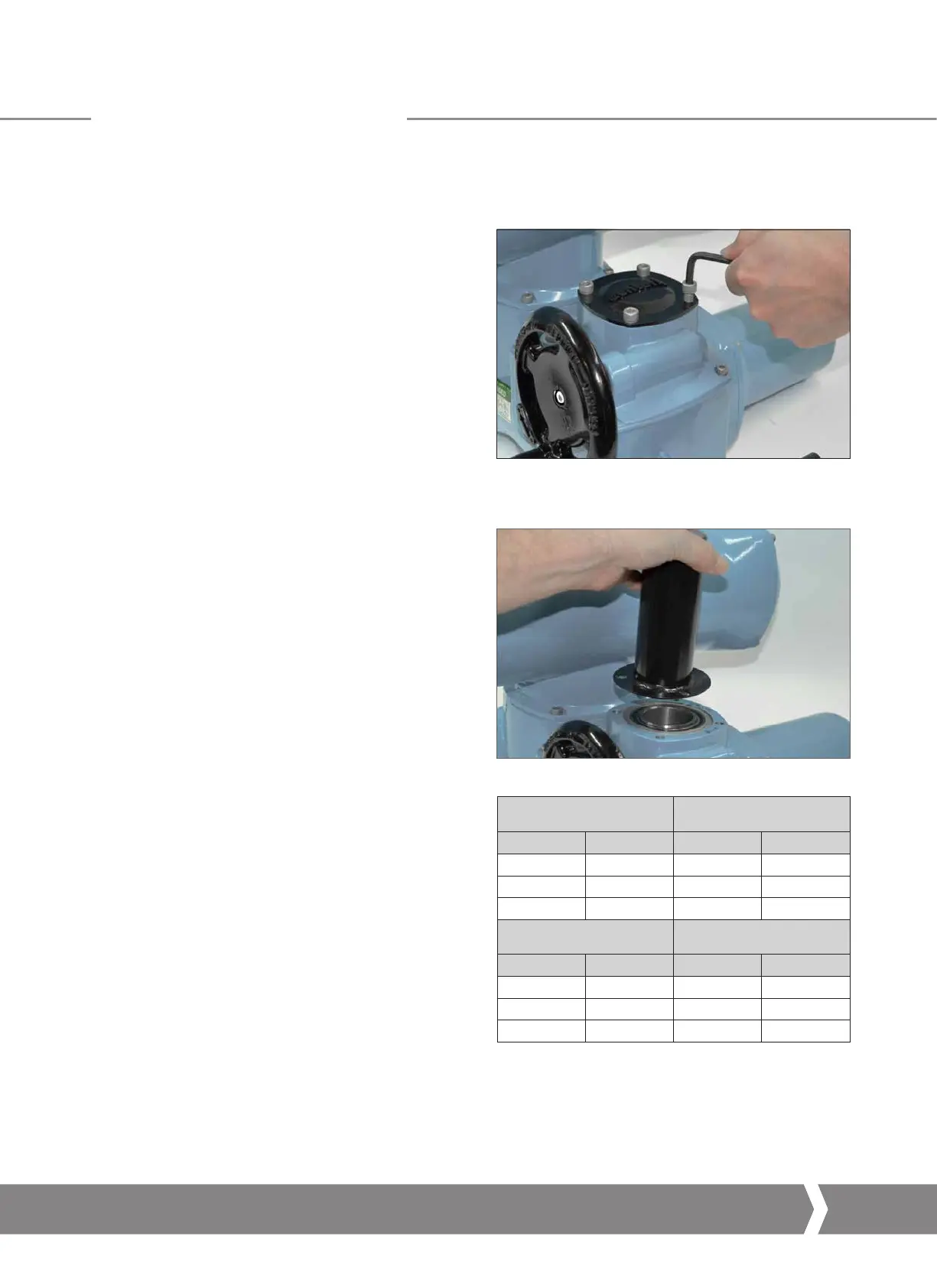

6.5 Actuator Sealing

Ensure that the sealing cap and o-ring assembly is securely fitted

to prevent moisture ingress into the centre column of the actuator.

For valves with rising spindles, a cover tube may be fitted.

Ensure that the o-ring is correctly fitted and that the cover

tube is secured with the supplied fasteners.

Metric Torque

Flange Fixing Nm lbf.ft

F07 M8 26.1 19.3

F10 M10 51.6 38

F14 M16 219.8 162.1

Imperial Torque

Flange Fixing Nm lbf.ft

FA07 5/16 24.3 17.9

FA10 3/8 42.3 31.2

FA14 5/8 205.3 151.4

Table A: Required Torque

Keeping the World Flowing

13

Loading...

Loading...