Keeping the World Flowing

13

12.0 Operation

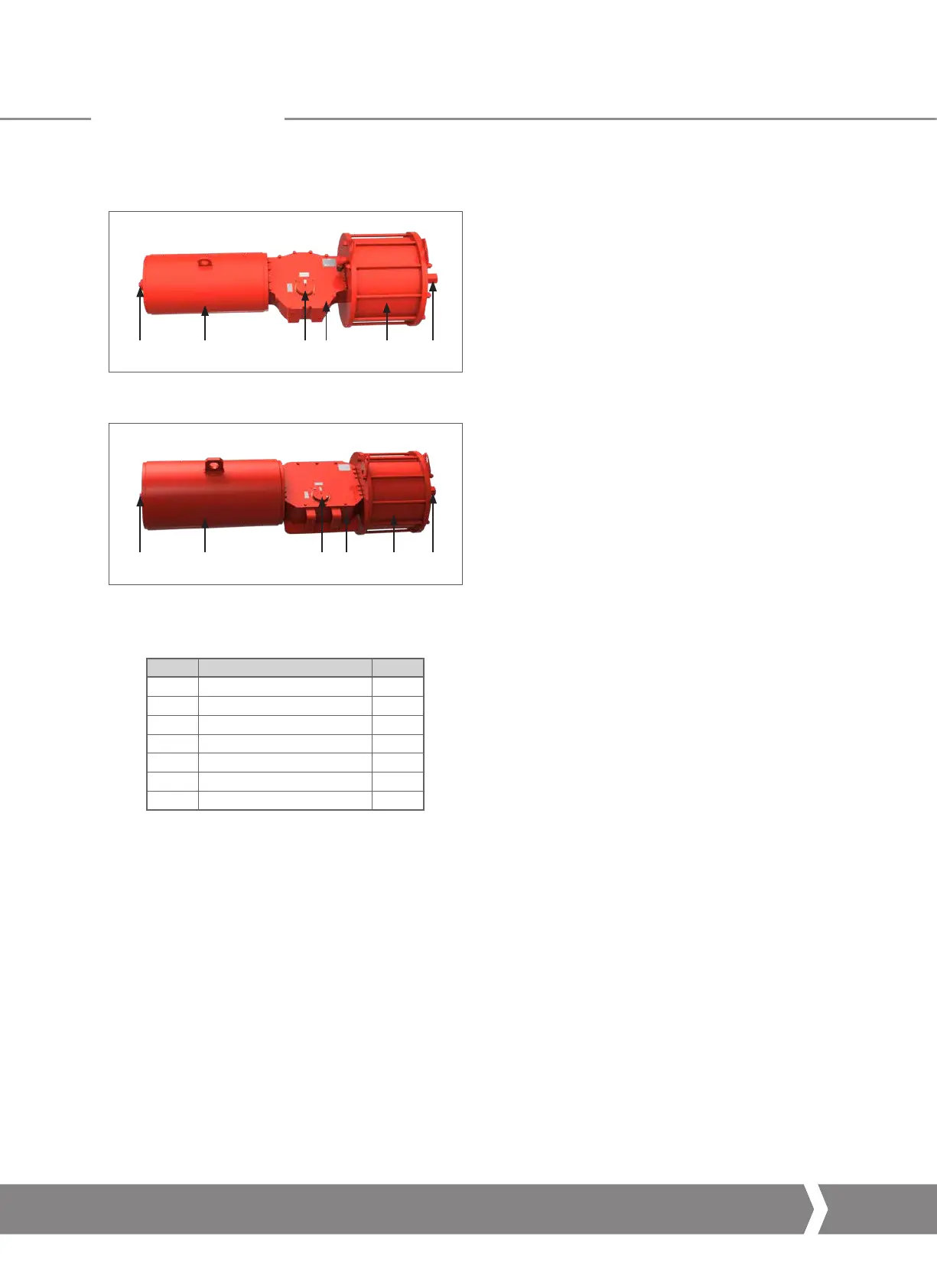

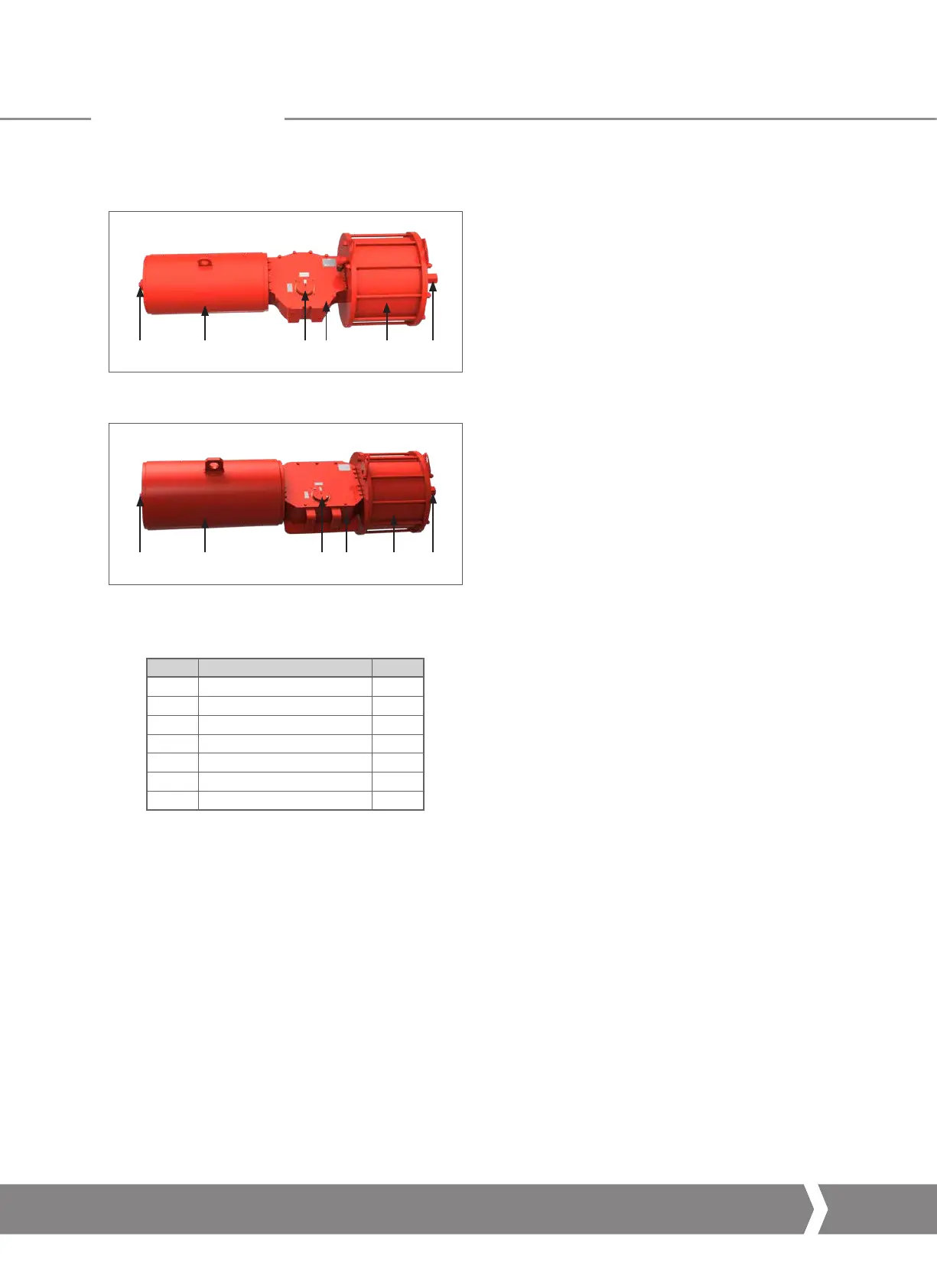

The main components of GP/S actuators are shown in

Fig 12.1, Fig 12.2 and Fig 12.3.

5 3 6 2.1 4 1

Fig 12.1 GP/S (cast body) main components

5 3 6 2.2 4 1

Fig 12.2 GP/S (welded body) main components

Table 1: GP/S Parts list

IT DESCRIPTION QTY

1 Mechanical stop bolt 1

2.1 Centre body (cast iron) 1

2.2 Centre body (welded) 1

3 Spring cartridge 1

4 Cylinder tube 1

5 Mechanical stop 1

6 Mechanical Visual Indicator

The GP/D series actuators are pneumatic double-acting

actuators specifically designed to provide efficiency and

reliability in heavy duty services.

Actuator general features are the same of the single-acting

version, except the spring canister that is replaced by the

centre body closure group.

Main components of a GP double-acting actuator are:

•

A

scotch-yoke mechanism

, which transforms the

linear movement of the pneumatic cylinder into a rotary

movement suitable for operating quarter-turn valves, such

as ball valves, butterfly valves or plug valves. It is available

in both “symmetric” and “canted” execution to meet

application specific valve torque demand requirements.

The scotch-yoke mechanism is situated in a perfectly

sealed housing, made of welded carbon steel or in cast

iron, acting as a protection against corrosion and that

guarantees safety of personnel during the operations.

Chromium plated guide bar suitable for supporting the

transverse forces and ensure the proper alignment of the

piston rod. The Chromium plating prevents corrosion and

minimizes sliding friction.

Sliding blocks and yoke bushings are made of bronze to

reduce friction and to guarantee a long working life.

•

A

pneumatic cylinder

, made of carbon steel.

The cylinder tube is nickel plated internally by electrolysis,

to assure perfect dynamic seal, corrosion resistance and

low friction.

The piston is made of carbon steel. The dynamic floating

piston seal further reduces friction and avoids stick-slip

effect even after prolonged periods without operation.

The sliding ring made of Teflon guides the piston in the

cylinder and ensure a good radial loading capacity.

A chromium plated piston rod ensures a perfectly

dynamic seal, corrosion resistance and low friction.

The dynamic cylinder seals are specifically designed to

enable the use without lubrication.

•

Two mechanical

stop bolts

to enable the adjustment of

valve angular stroke.

•

A

mechanical visual position indicator

directly

connected to the valve stem that shows the position of

the valve all along the actuator stroke.

A4 US

US

A4

US

A4

A4 US

Loading...

Loading...