Installation, Commissioning and Maintenance Manual

30

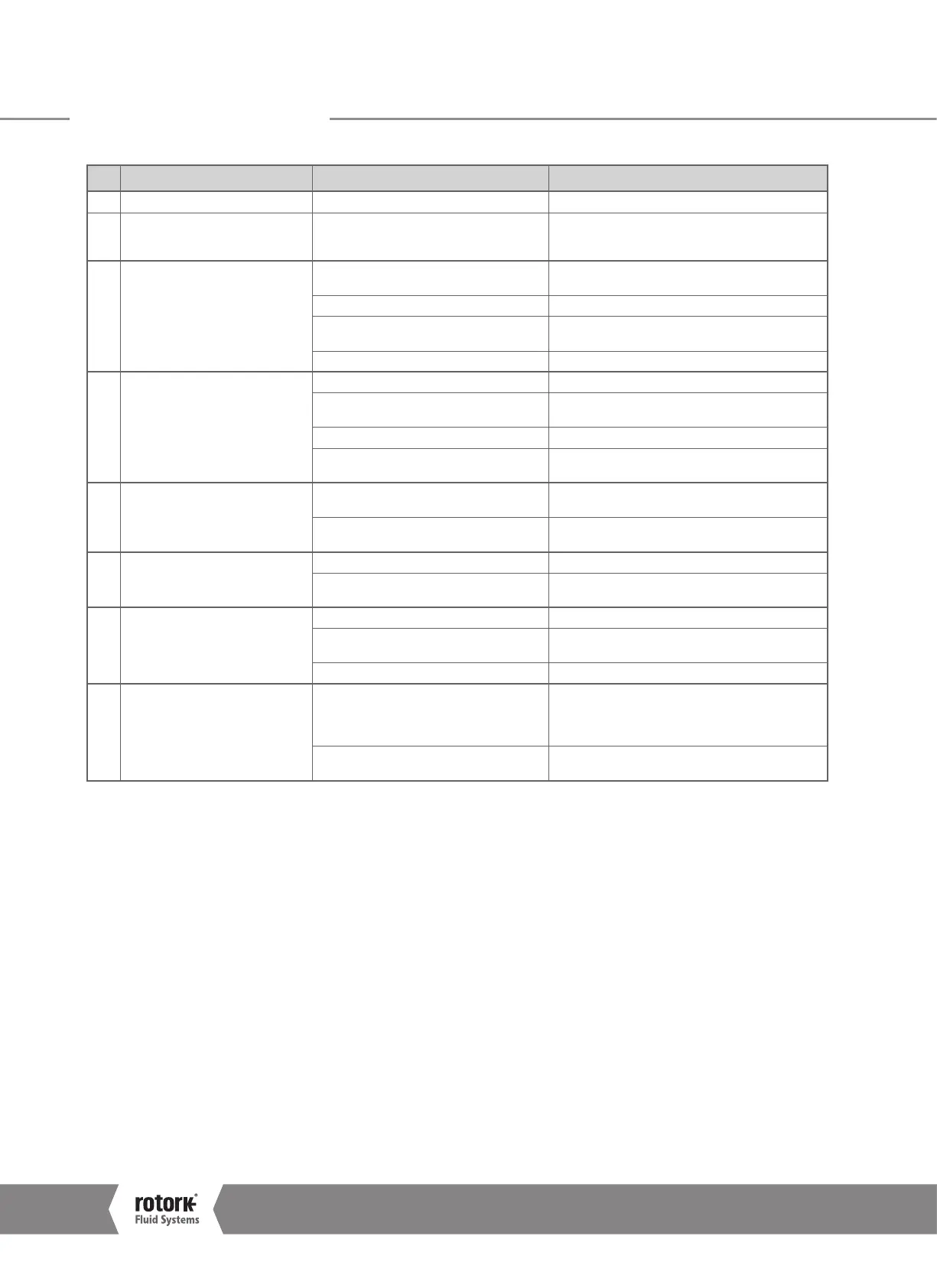

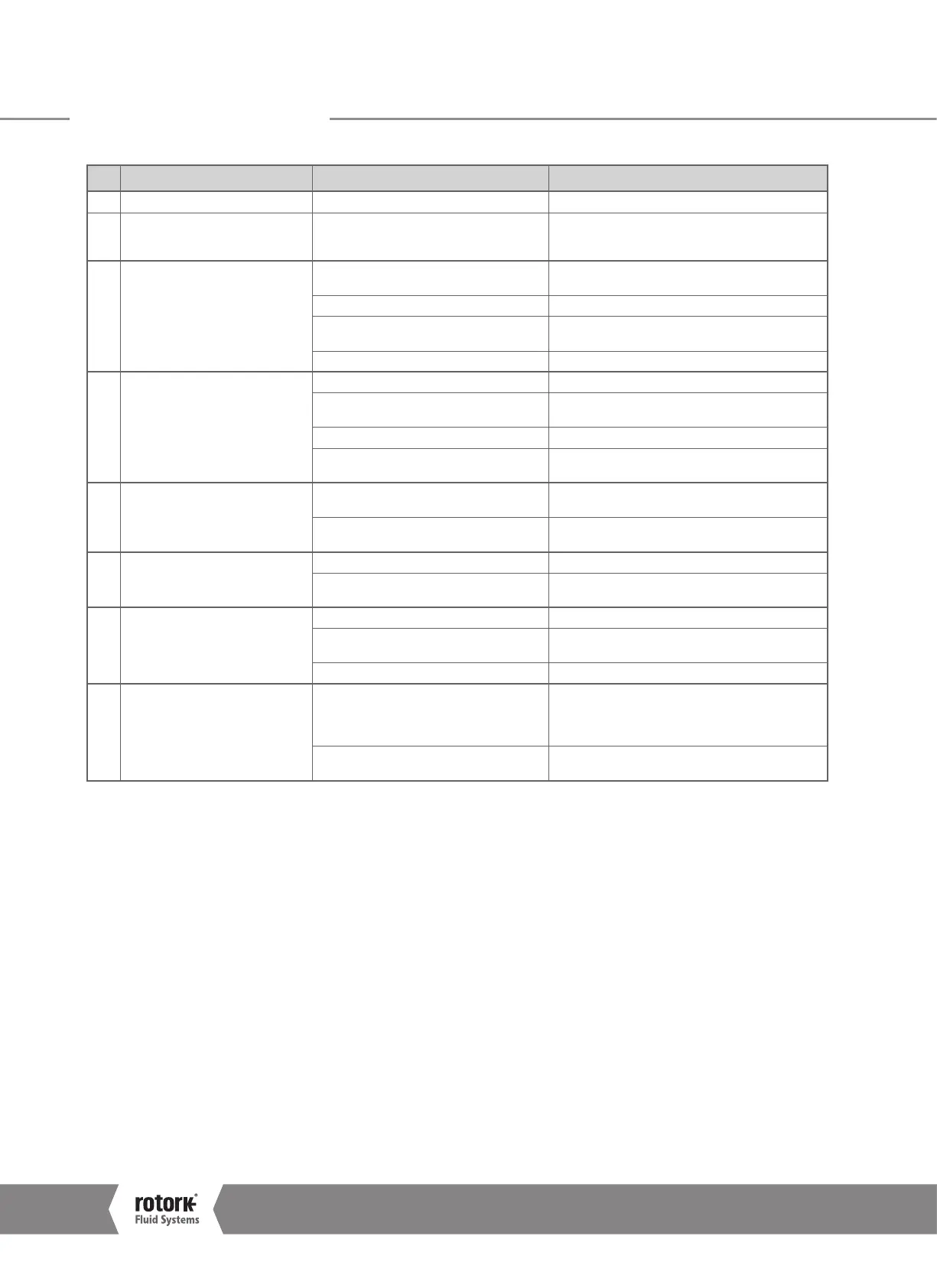

ID FAILURE POSSIBLE CAUSES CORRECTIVE MEASURES

1 Incorrect valve position •

Fault of pipeline valve

•

Consult the valve manufacture’s documentation

2 Incorrect indication of valve position •

Incorrect signal from limit switches

•

Check limit switches position (according

instructions reported in the job specific

documentation)

3 Incorrect movement

•

Irregular supply of operating medium

•

Verify the supply pressure and adjust as

necessary

•

Worn parts

•

Contact Rotork Fluid Systems

•

Fault in control panel equipment

(if present)

•

Contact Rotork Fluid Systems Customer Service

•

Fault of pipeline valve

•

Consult the valve manufacture’s documentation

4 Valve stroke not fully completed

•

Insufficient gas flow

•

Increase gas supply flow

•

Incorrect assembly between actuator

and valve

•

Perform assembling according to INSTALLATION

ON VALVE, page 10

•

Valve blocked

•

Consult the valve manufacture’s documentation

•

Stop bolts wrong setting

•

Adjust stop bolt setting following instructions in

ANGULAR STROKE SETTING, page 17

5 Leakages

•

Stop bolts wrong setting

•

Adjust stop bolt setting following instructions in

ANGULAR STROKE SETTING, page 17

•

Worn seals

•

Replace seals according instructions reported in

PM-GP-006, PM-GP-007

6 Actuator moves too fast

•

No pressure on pipeline

•

Restore pipeline pressure

•

Supply pressure greater than allowed

range values

•

Verify the supply pressure and adjust as

necessary

7 Actuator moves too slow

•

Fault on pipeline valve (valve hardened)

•

Consult the valve manufacture’s documentation

•

Supply pressure lower than allowed

range values

•

Verify the supply pressure and adjust as

necessary

•

Possible internal undue friction

•

Contact Rotork Fluid Systems Customer Service

8 Loss of power

•

Inadequate supply pressure

•

Ensure that the supply pressure is above the

minimum operating pressure of the actuator

and that the output torque produced at supply

pressure exceeds the required valve torque.

•

Leakage from cylinder

•

Replace seals according instructions reported in

PM-GP-006, PM-GP-007

For other problems, please contact Rotork Fluid Systems Customer Service.

15.0 Troubleshooting

A4US

US

A4

US A4

US

A4

Loading...

Loading...