Keeping the World Flowing

27

12.8 Pneumatic Power Supply

Verify allowed supply pressure range on actuator label.

Verify medium composition. Contact Rotork Fluid

Systems to check the compatibility with the supply

medium.

12.9 Pneumatic Connections

Preliminary Operations

A. Verify sizes of pipes and fittings per applicable plant

specifications

B. Clean the inside of the connection pipes by washing them

with a suitable detergent and by blowing air into them

C. The connecting pipes must be properly shaped and fixed

to prevent stress or loosening of threaded connections

Note: For tapered-thread fluid connections, apply a

thin layer of thread sealing product (Loctite 577 or

equivalent) to ensure a good seal.

Connect the pneumatic power source in accordance

to the applicable operating diagram, please refer to

specific job for details.

Depending upon the control circuit design,

pneumatically powered actuators may exhaust the

power supply gas into the atmosphere during normal

operation. This may present an unacceptable hazard.

Do not feed a single-acting actuator from the

spring container side after having removed the exhaust

silencer, especially if the line valve is blocked.

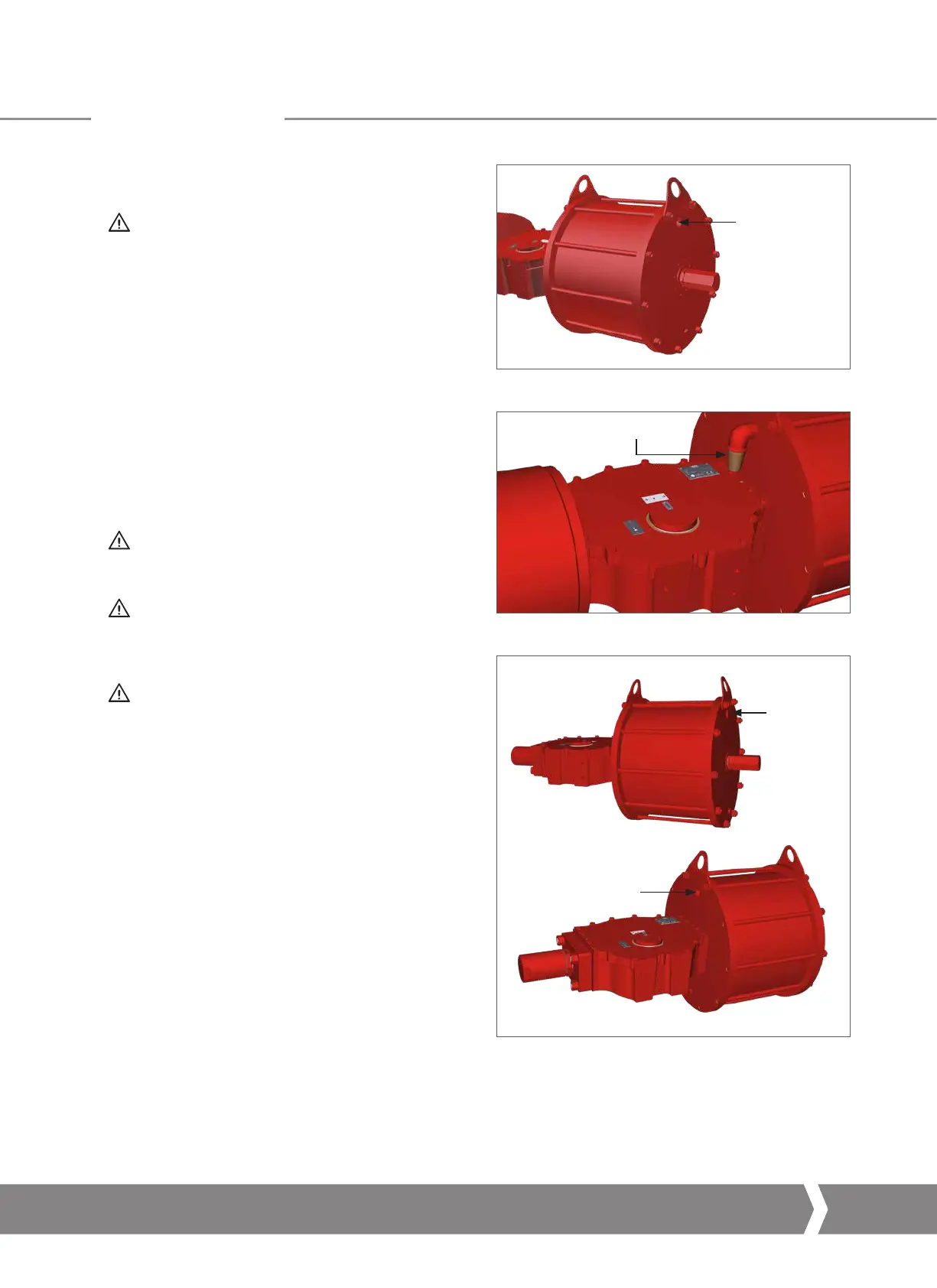

Inlet port

Fig 12.14 Inlet port for Single-acting actuator

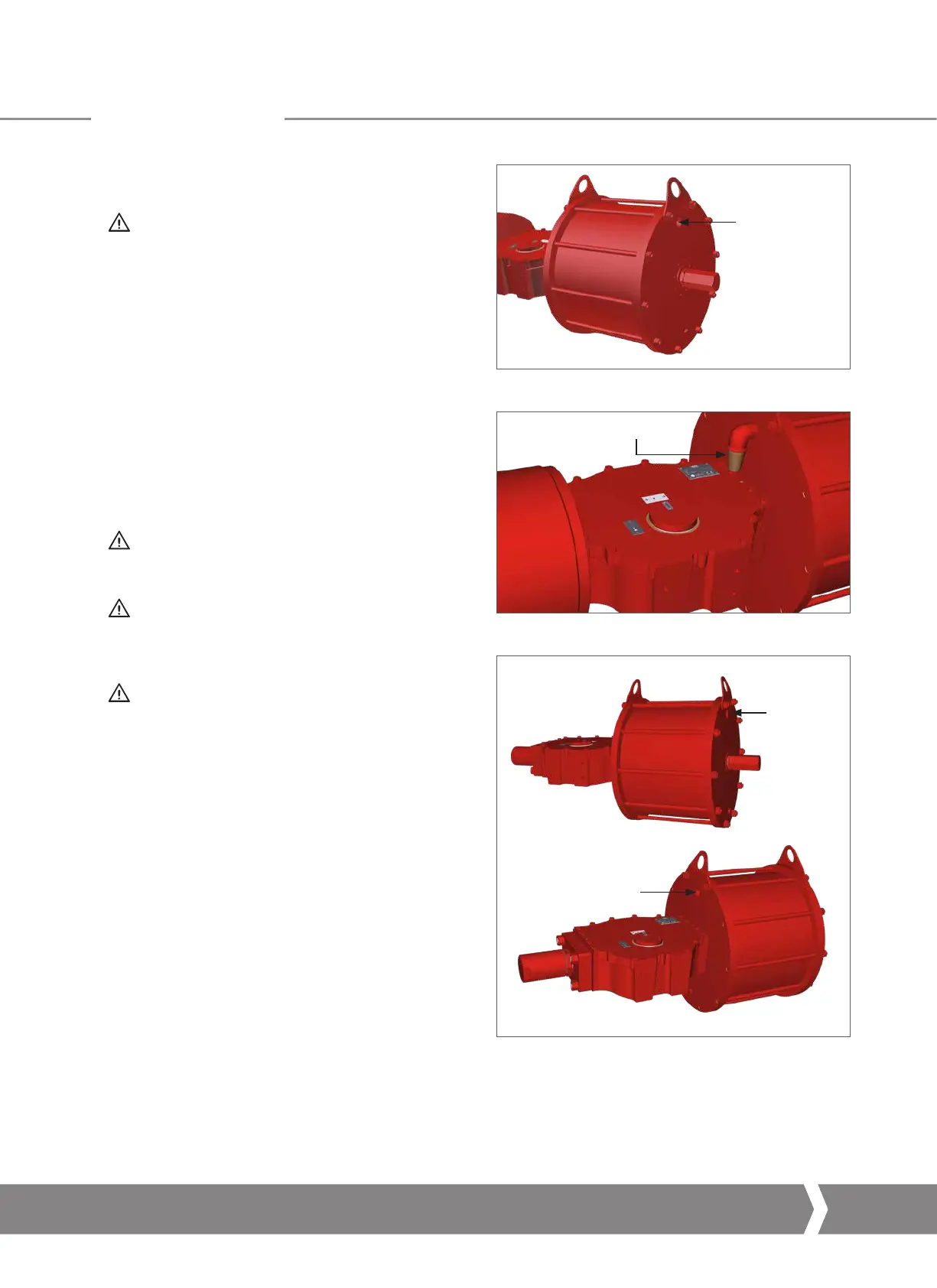

Exhaust port

Fig 12.15 exhaust port for Single-acting Actuator

Inlet/exhaust

port

Inlet/exhaust port

Fig 12.16 Inlet exhaust port for Double-acting actuator

12.0 Operation

A4 US

US

A4

US

A4

A4 US

Loading...

Loading...