Keeping the World Flowing

77

18.0 Grease & Hydraulic Oil Specification

In general, there is no need to lubricate the actuator because

its mechanism is lubricated for life. The standard grease for

Rotork Fluid Systems scotch yoke actuators are shown below.

If an alternative was specified and/or supplied, please refer to

the job specific documentation.

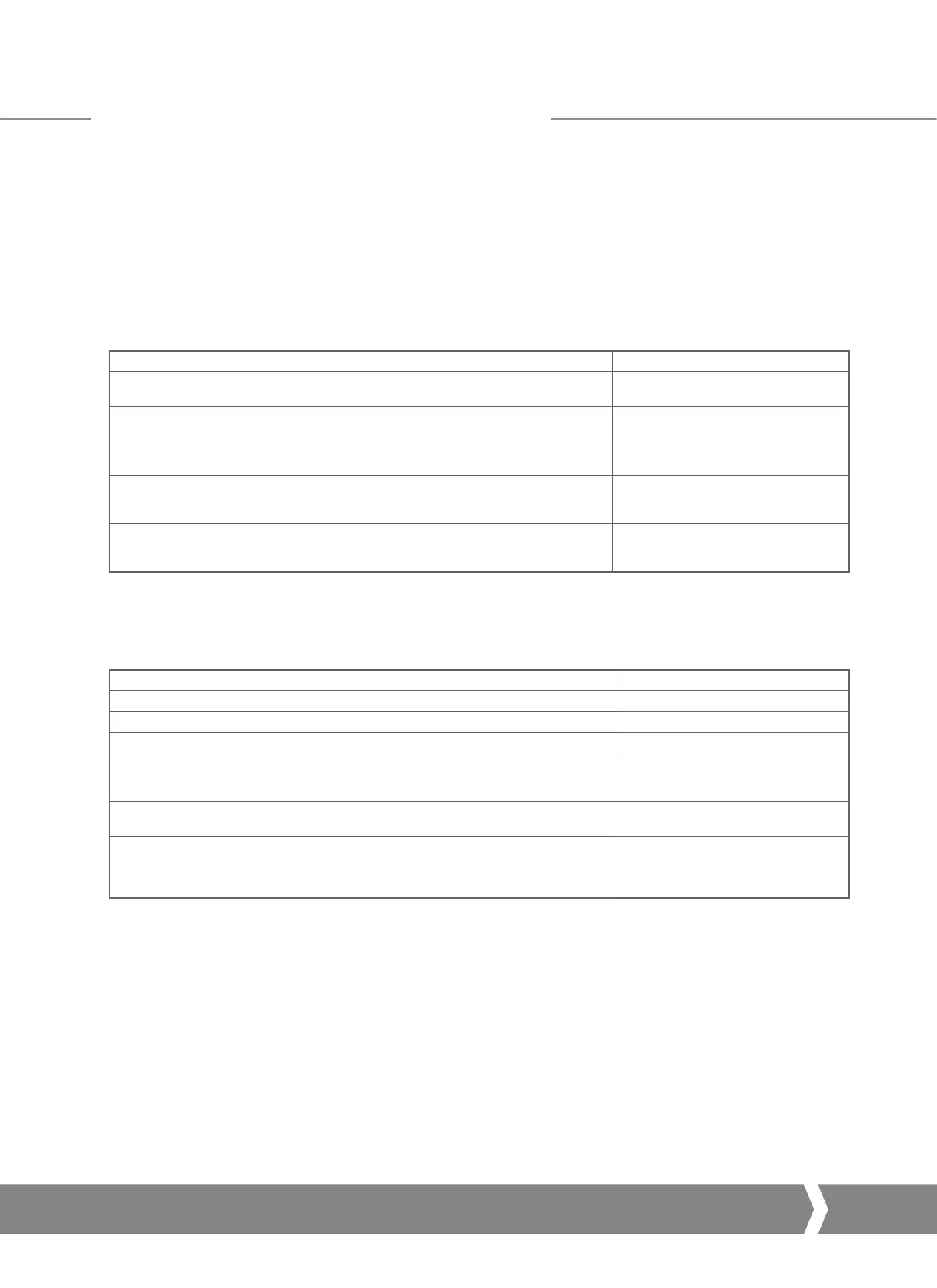

18.1 Grease

Lubricate mechanical sliding components of the scotch

yoke actuators using the following grease or equivalent for

temperature range -30° < T < +100 °C.

Manufacturer: Dow Corning Corporation

Trade name:

Colour:

MOLIKOTE

®

P40

Clear Brown

Unworked penetration (ISO 2137):

Viscosity of oil at 40 °C (104°F) (DIN 51 562):

310-350 mm/10

360 mm

2

/s

Service temperature:

Drop point (ISO 2176):

-40 to 230 °C (-40 to 446 °F)

None

Four ball tester

Weld load (Din 51 350 pt.4)

Wear scar under 800N load (Din 51 350 pt.5)

3000 N

0.94 mm

Coefficient of friction

[1]

Screw test - µ thread

Screw test - µ head

0.16

0.08

1. Coefficient of friction in bolted connection, M12x1.75, 8.8, on blackened surface.

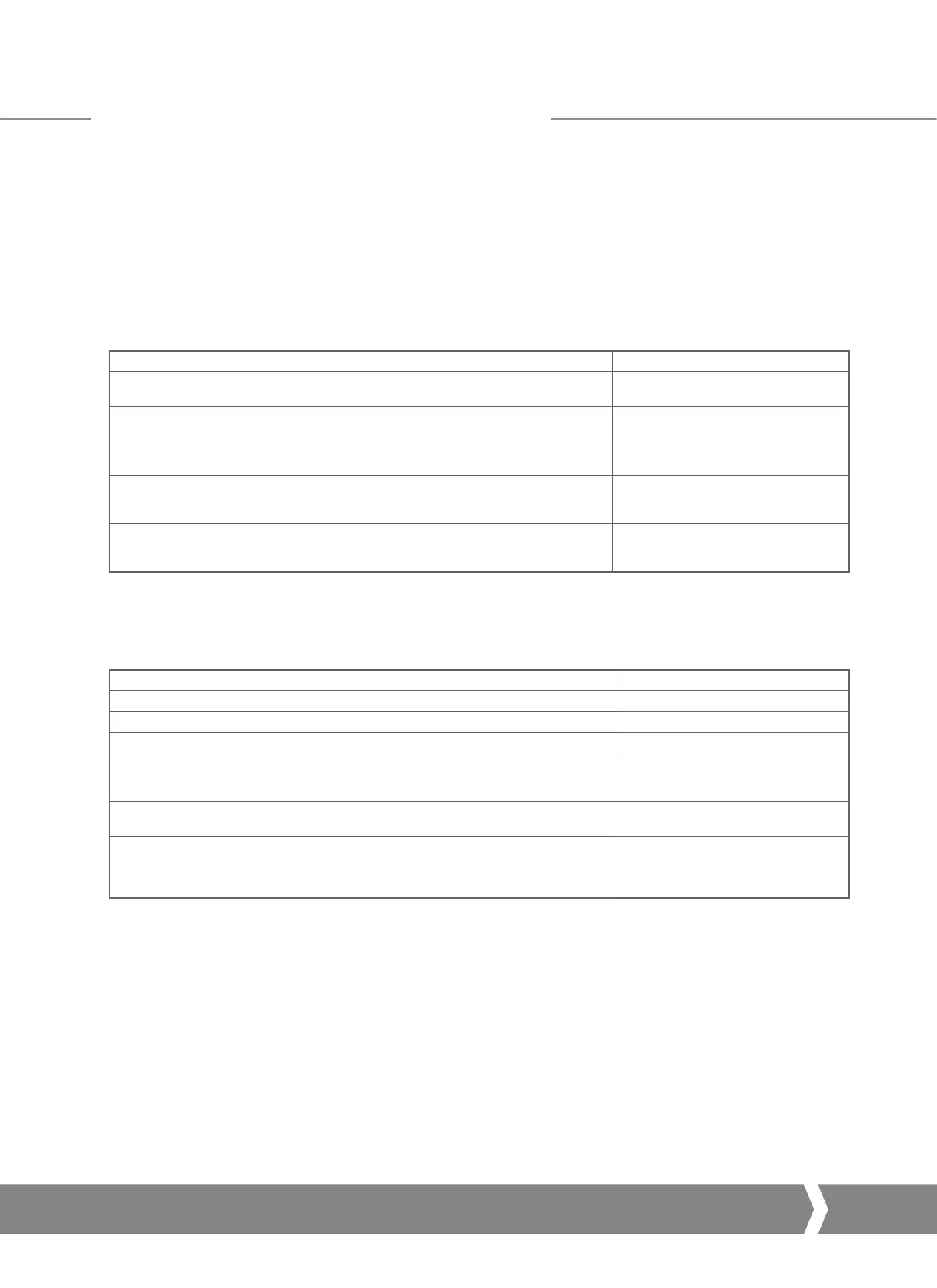

Lubricate mechanical sliding components of the scotch

yoke actuators using the following grease or equivalent for

temperature range -60° < T < +100 °C.

Manufacturer: Mobil

Trade name: MOBILTHHEMP

®

SHC100TM

NLGI grade: 2

Colour: Clear brown

Penetration, density, viscosity

Worked penetration at 25 °C (ASTM D 217):

Viscosity of oil at 40 °C (104 °F) (ASTM D445):

280

100 CSt

Temperature

Drop point (ASTM D 2265): >260 °C

Load-carrying capacity, wear protection, service life

Four ball tester (ASTM D 2266)

Weld load (ASTM D 2596)

Corrosion protection (ASTM D6138)

0.4 mm

>200

0

A4 US

US

A4

US

A4

A4 US

Loading...

Loading...