Installation, Commissioning and Maintenance Manual

54

PM-GP-006 Page: 17/17

Component: Single-Acting actuator / Double-Acting actuator Task: Pneumatic cylinder and centre body seals replacement

Equipment, Tools, Materials:

Spare seals

Wrench

Lifting tools

Project documentation

Warnings:

Preliminary Operations: Removal from Valve

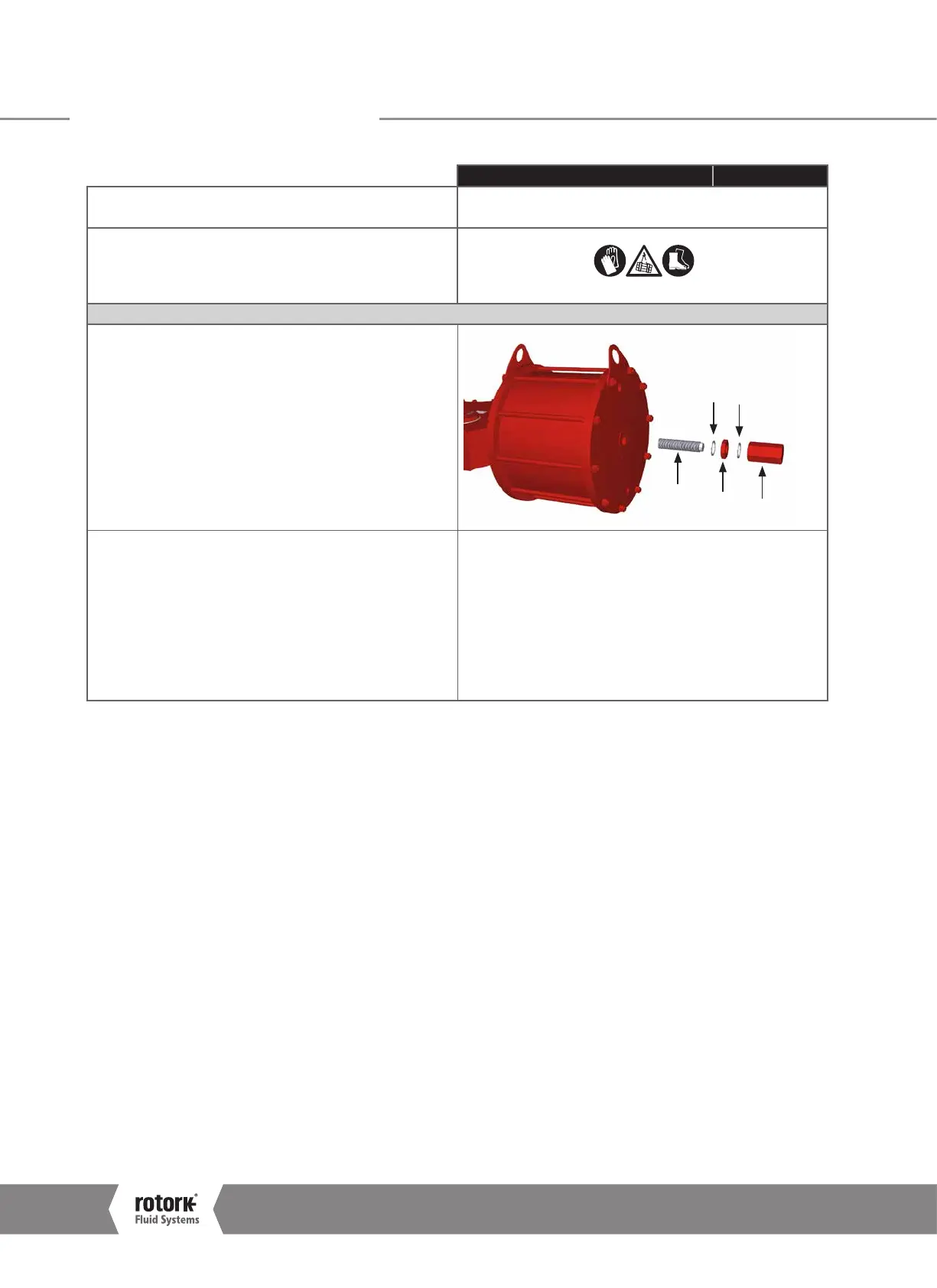

80. With the help of a wench, screw the stop bolt (7) into the

cylinder flange

81. Insert the seal washer (5) and, holding the stop bolt (7) with a

wrench, tighten the stop nut (6)

82. Insert the second seal washer (5) and tighten the cap nut (4)

83. Note: before tightening both the stop nut (6) and the cap nut

(4), always make sure the two washers (5) are correctly

positioned

Please refer to page 17 of the present document for the instructions

to regulate the stop bolt position.

7

6

4

5

5

84. Assemble the components on the centre body cover (if any)

85. Assemble the control panel, if any, on the central body

The actuator must be tested before it is assembled on the valve.

86. Place the actuator in a stable position, e.g. on a workbench

87. Connect the pneumatic supply to the actuator and cycle the

actuator several times, verify smooth functioning and absence

of leakages

88. Check painted parts, if necessary repaint them per the

applicable painting specifications

The actuator is now ready to be assembled on the valve.

16.0 Periodic Maintenance

A4US

US

A4

US A4

US

A4

Loading...

Loading...