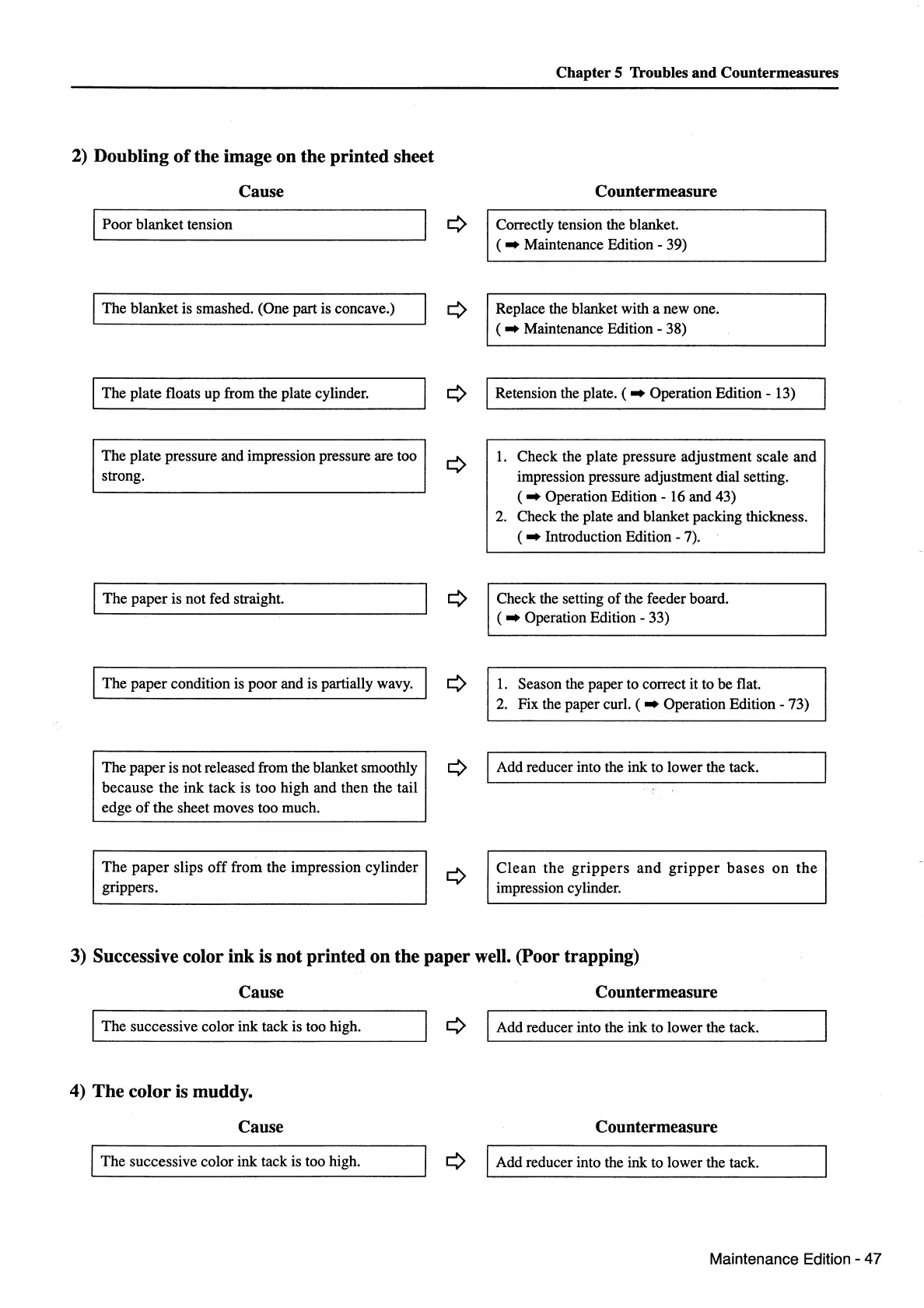

2) Doubling

of

the image on the printed sheet

Cause

I Poor blanket tension

The blanket

is

smashed. (One part is concave.)

The plate floats up from the plate cylinder.

The plate pressure and impression pressure are too

strong.

I The paper is not fed straight.

The paper condition is poor and is partially wavy.

The paper is not released from the blanket smoothly

because the ink tack is too high and then the tail

edge

of

the sheet moves too much.

The

paper

slips

off

from the impression cylinder

grippers.

Chapter 5 Troubles and Countermeasures

Countermeasure

Correctly tension the blanket.

( • Maintenance Edition - 39)

Replace the blanket with a new one.

( • Maintenance Edition - 38)

Retension the plate. ( • Operation Edition- 13)

1.

Check the plate pressure adjustment scale and

impression pressure adjustment dial setting.

( • Operation Edition-

16

and 43)

2.

Check the plate and blanket packing thickness.

( • Introduction Edition -

7).

Check the setting

of

the feeder board.

( • Operation Edition - 33)

1.

Season the paper to correct it to be flat.

2.

Fix the paper curl. ( • Operation Edition - 73)

I Add reducer into the ink to lower the tack.

Clean

the

grippers

and

gripper

bases

on

the

impression cylinder.

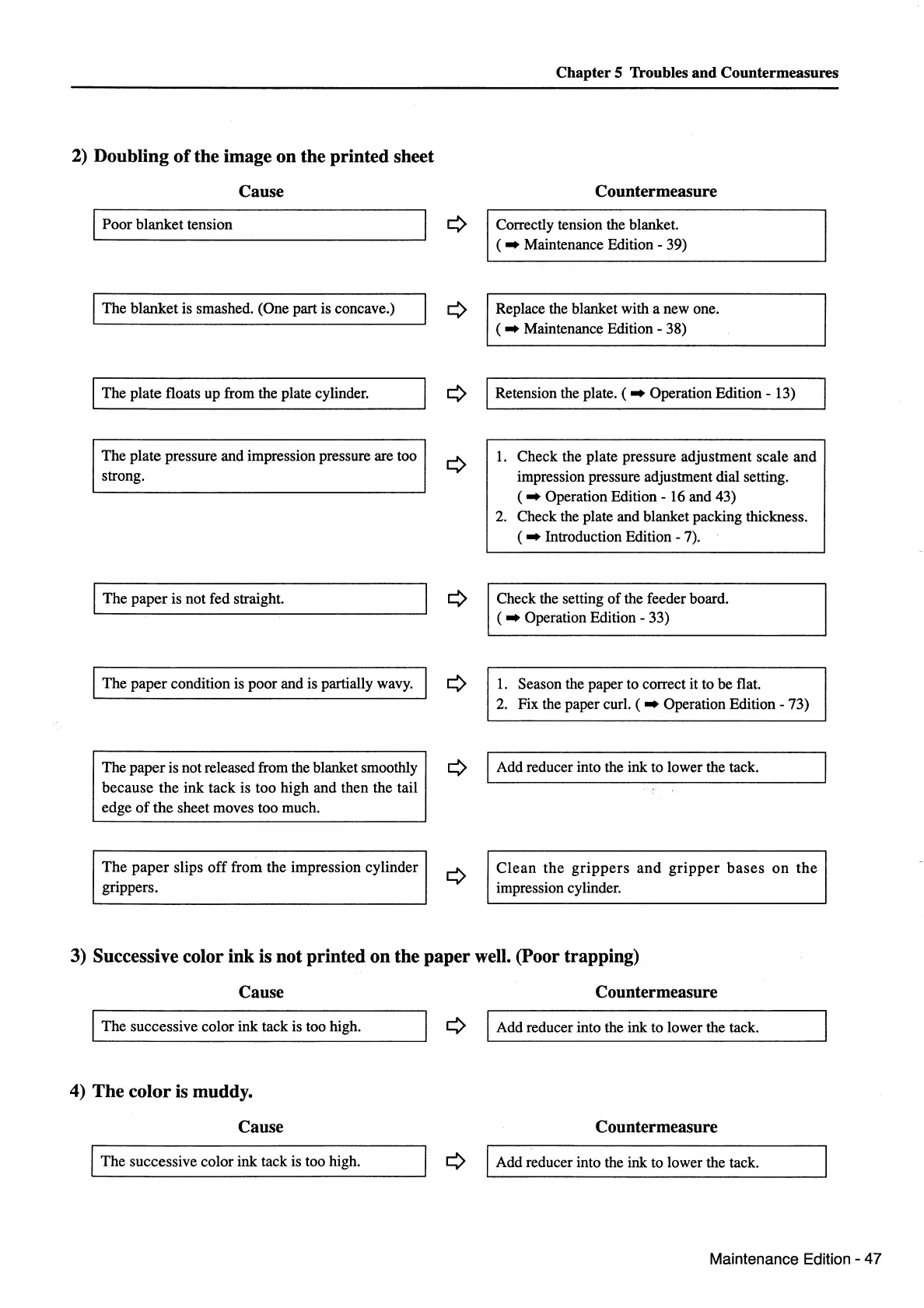

3) Successive color ink is not printed on the paper well. (Poor trapping)

Cause Countermeasure

I The successive color

ink

tack is too high.

¢ I Add reducer into the ink to lower the tack.

4) The color is muddy.

Cause

Countermeasure

The successive color ink tack is too high.

¢ I Add reducer into the ink to lower the tack.

Maintenance Edition- 47

Loading...

Loading...