SINUS MINI High performance Vector Control Inverter User Manual

48

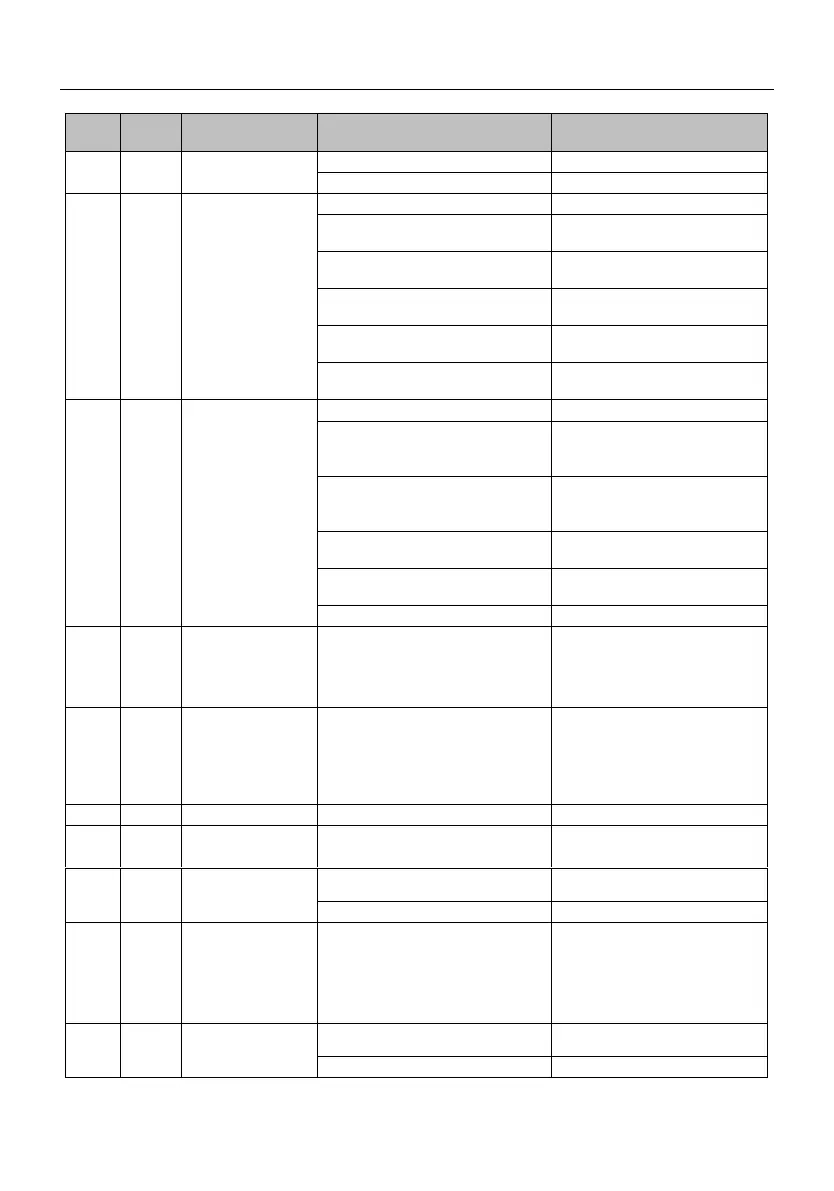

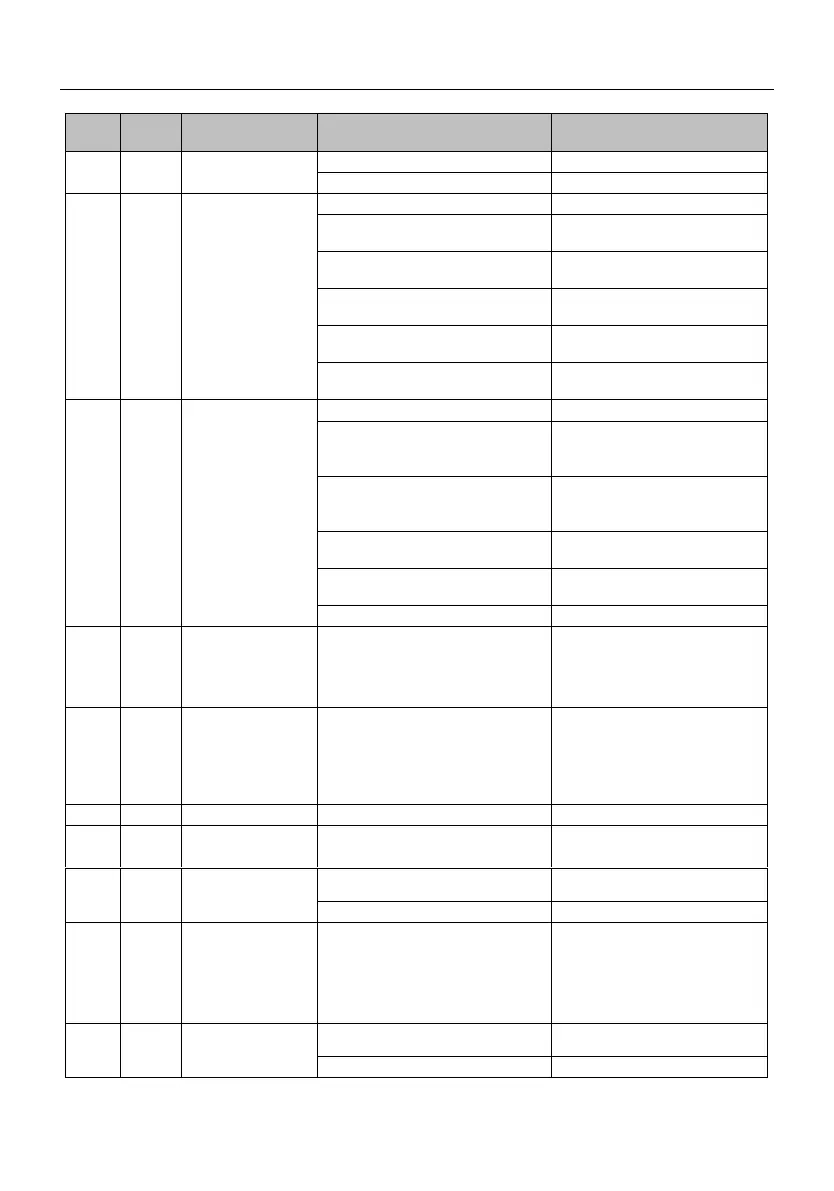

Seek for technical support

Temperature detection circuit failure

Seek for technical support

Inverter overload

protection

Input power under voltage

Fast start-up when motor operates

with high speed

Start again after the motor stop

rotating

Keep overloading for a long period of

time

Shorten the overloading time and

reduce load

Acceleration and deceleration time is

too short

Prolong the

acceleration/deceleration time

V/F curve ratio is set too large

Adjust V/F curve setting and

torque boost

Power level of inverter is small

Replace to inverter with proper

model

Motor overload

protection

Input power under voltage

Motor rotation is blocked or load

mutation occurs

Prevent the motor rotation from

blocking and reduce the load

mutation

Common motor maintains running

under heavy load for a long period of

time

Replace the common motor with

variable frequency motor or

improve the running frequency

Motor overload protection time is set

too small

Increase the motor overload

protection time

V/F curve ratio is set too large

Adjust V/F curve setting and

torque increment

DC braking current is set too high

Reduce the DC brake current

There is abnormal connection,

missing connection or disconnection

at the power terminal of the inverter

Check the power connections as

per the operational regulations

and eliminate the errors of

missing connection and

disconnection

Abnormal output

phase loss

There is abnormal connection,

missing connection or disconnection

at the output side of the inverter

Check the power connections at

the output side of the inverter as

per the operational regulations

and eliminate the errors of

missing connection and

disconnection

EEPROM reading and writing failure

Seek for technical support

Seek for technical support

Keypad

communication

fault

Keypad or its control line failure;

Check the connection of Keypad

and its control line.

Seek for technical support

parameter setting

failure

In traverse or three-wire operation

mode, wrong parameter setting

Communication

abnormal 2

(Terminal 485)

The communication of terminal 485

is disconnected

Check the connection of the

equipment communications

The baud rate is set improperly

Loading...

Loading...