SRT55D Off-Highway Truck

5-1

Safety, Operation and Maintenance Manual

Fig. 5-2

5 WORKING THE TRUCK

5.1 Working the Truck

Off-Highway trucks are used on a variety of

hauling jobs, from mine overburden removal

to dam building. Every truck operation,

regardless of the type of job, can be divided

into four phases; loading, hauling, dumping

and the empty return.

Note:

After coming to a stop for loading or

unloading the truck, the Parking-Emergency

brake button can be pushed in to hold the

brakes in the applied position as though the

foot brake is depressed.

5.2 Loading

The most common methods of loading trucks

are with hydraulic excavators, rope shovels,

and front end loaders. For maximum material

movement, the truck operator must help the

loading machine operator hold loading time to

a minimum. The fewer manoeuvres the truck

must make to get into loading position, the

sooner loading can start. And the shorter the

distance the loading unit bucket must travel

between the cut, or stockpile and the truck

body, the more passes it can make in a given

period of time and the quicker the truck can be

loaded.

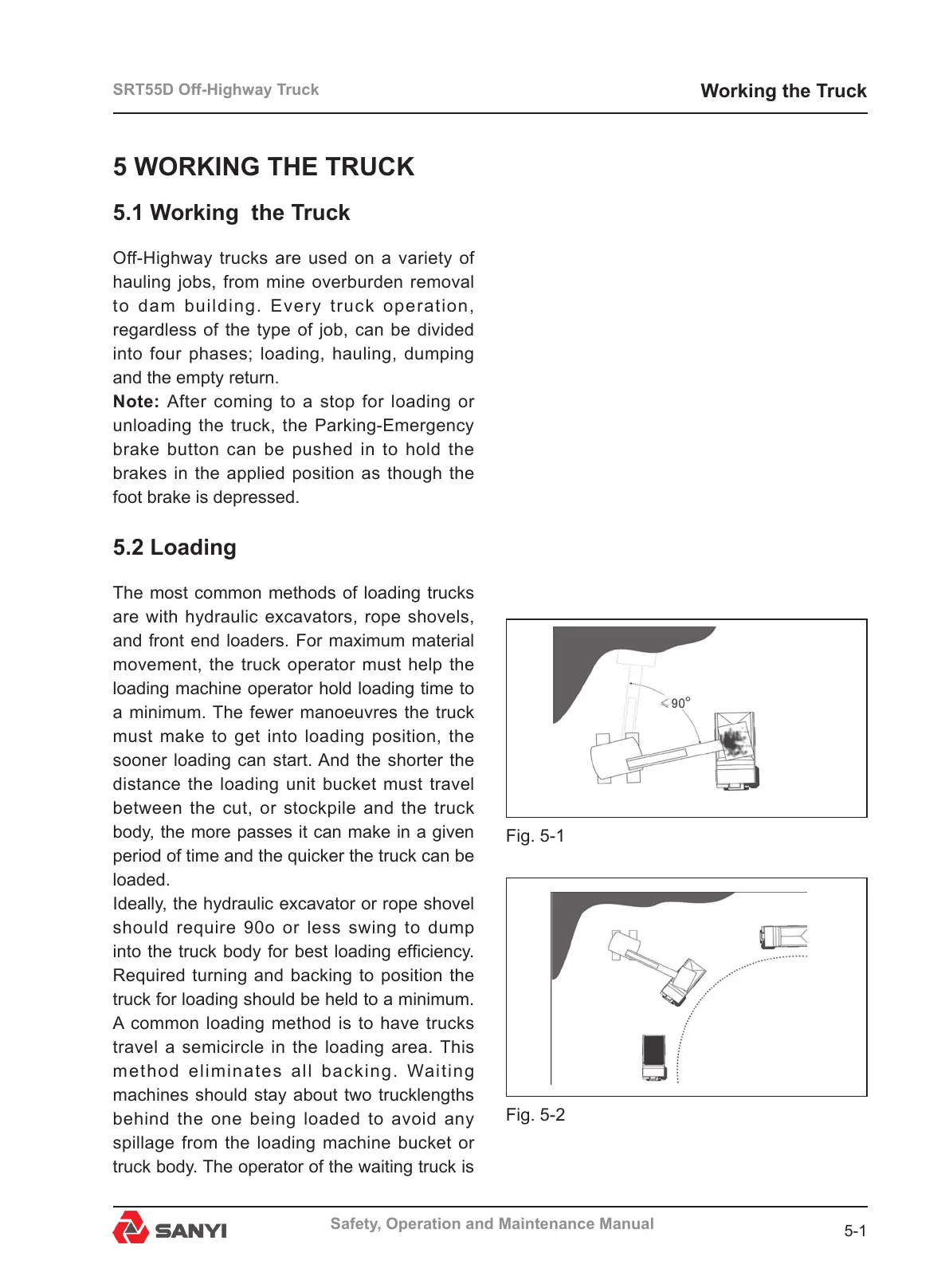

Ideally, the hydraulic excavator or rope shovel

should require 90o or less swing to dump

into the truck body for best loading efciency.

Required turning and backing to position the

truck for loading should be held to a minimum.

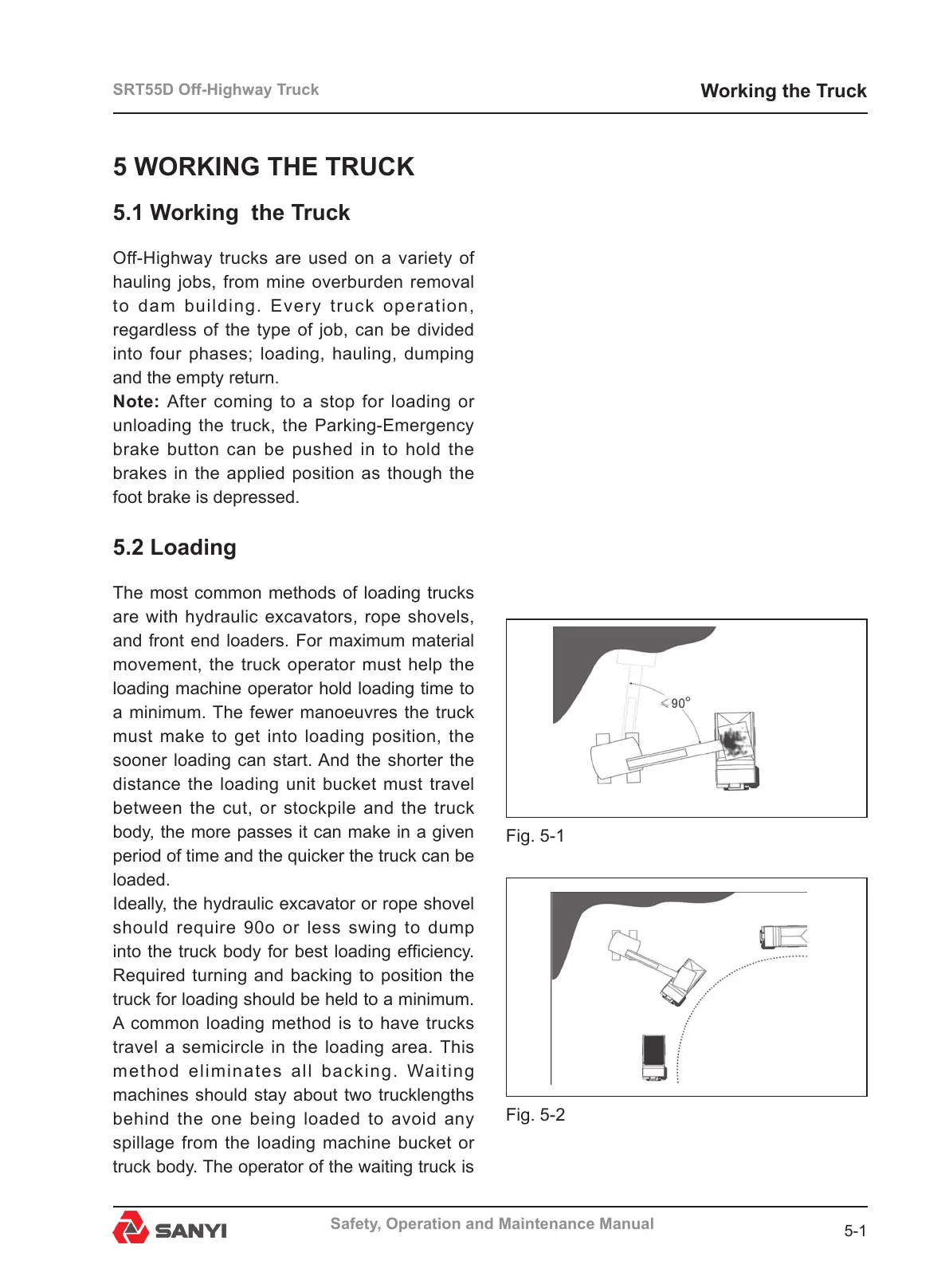

A common loading method is to have trucks

travel a semicircle in the loading area. This

method eliminates all backing. Waiting

machines should stay about two trucklengths

behind the one being loaded to avoid any

spillage from the loading machine bucket or

truck body. The operator of the waiting truck is

Fig. 5-1

Working the Truck

Loading...

Loading...