13

11063344 • Rev EA • Dec 2012

H1 Axial Piston Pump, Size 045/053, Single

Technical Information

General Technical Specications

Electrical Displacement

Control (EDC)

Options

A2 (12 V)/A3 (24 V)

(continued)

Control response

H1 controls are available with optional control passage orices to assist in matching

the rate of swashplate response to the application requirements (e.g. in the event of

electrical failure). Software ramp or rate limiting should be used to control vehicle

response in normal operation. The time required for the pump output ow to change

from zero to full ow (acceleration) or full ow to zero (deceleration) is a net function of

spool porting, orices, and charge pressure. A swashplate response table is available

for each frame indicating available swashplate response times. Testing should be

conducted to verify the proper software and orice selection for the desired response.

H1 pumps are limited in mechanical oricing combinations. Software is envisioned

as the means to control the swashplate response in normal operating conditions.

Mechanical servo orices are to be used only for fail-safe return to neutral in the event of

an electrical failure.

Typical response times shown below at the following conditions:

∆p = 250 bar [3626 psi]

Viscosity and temperature = 30 mm

2

/s (50 °C) [141 SUS (122 °F)]

Charge pressure = 20 bar [290 psi]

Speed = 1800 min

-1

(rpm)

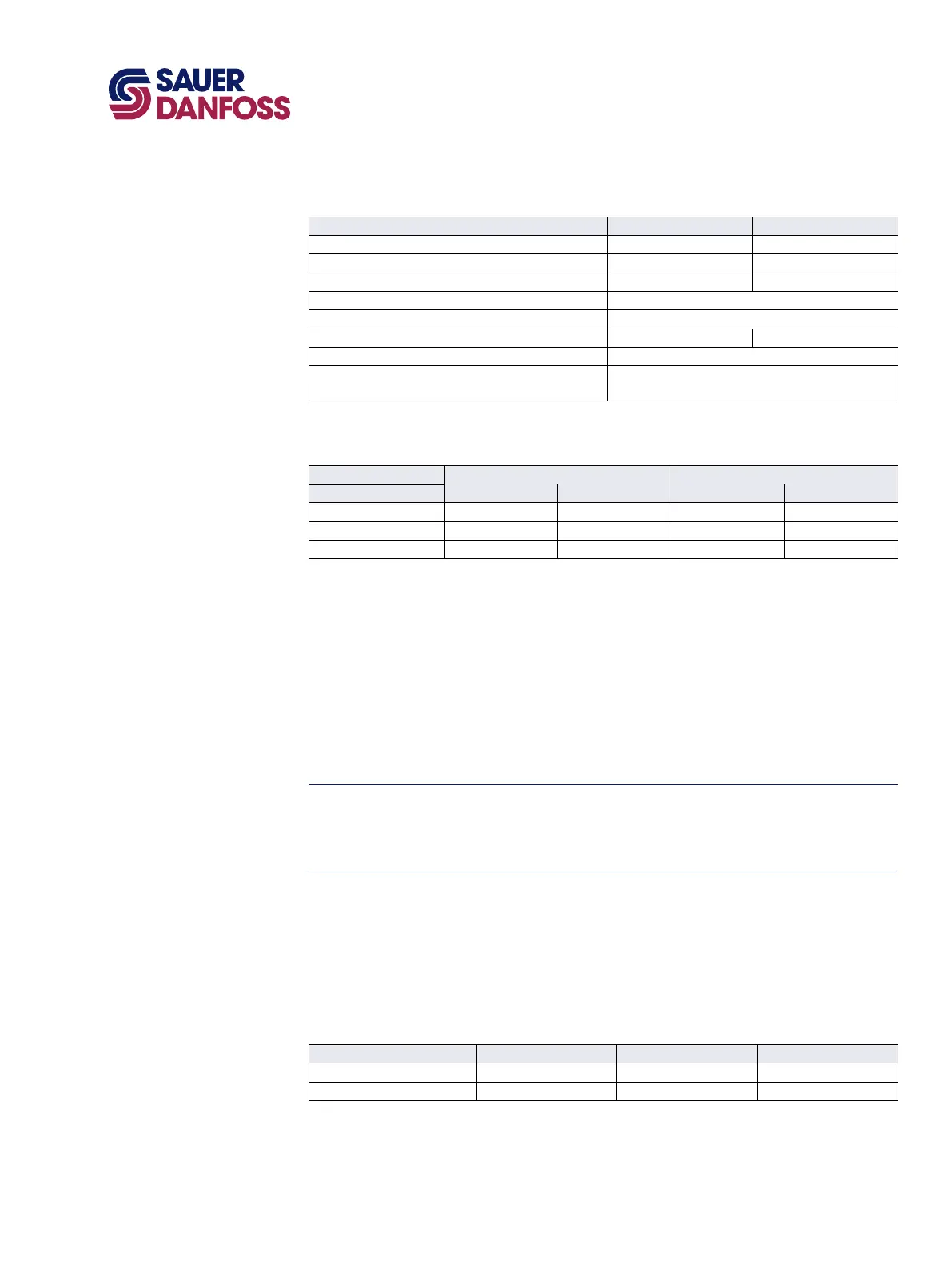

Flow table

Shaft rotation CW CCW

Coil energized* C2 C1 C2 C1

Port A in out out in

Port B out in in out

Servo port pressurized M5 M4 M5 M4

* For coil location see installation drawings.

T000 136E

Response times

Stroking direction 0.8 mm [0.03 in] Ori ce 1.3 mm [0.05 in] Ori ce No ori ce

Neutral to full ow 1.7 s 0.9 s 0.5 s

Full ow to neutral 1.1 s 0.6 s 0.3 s

T000 177E

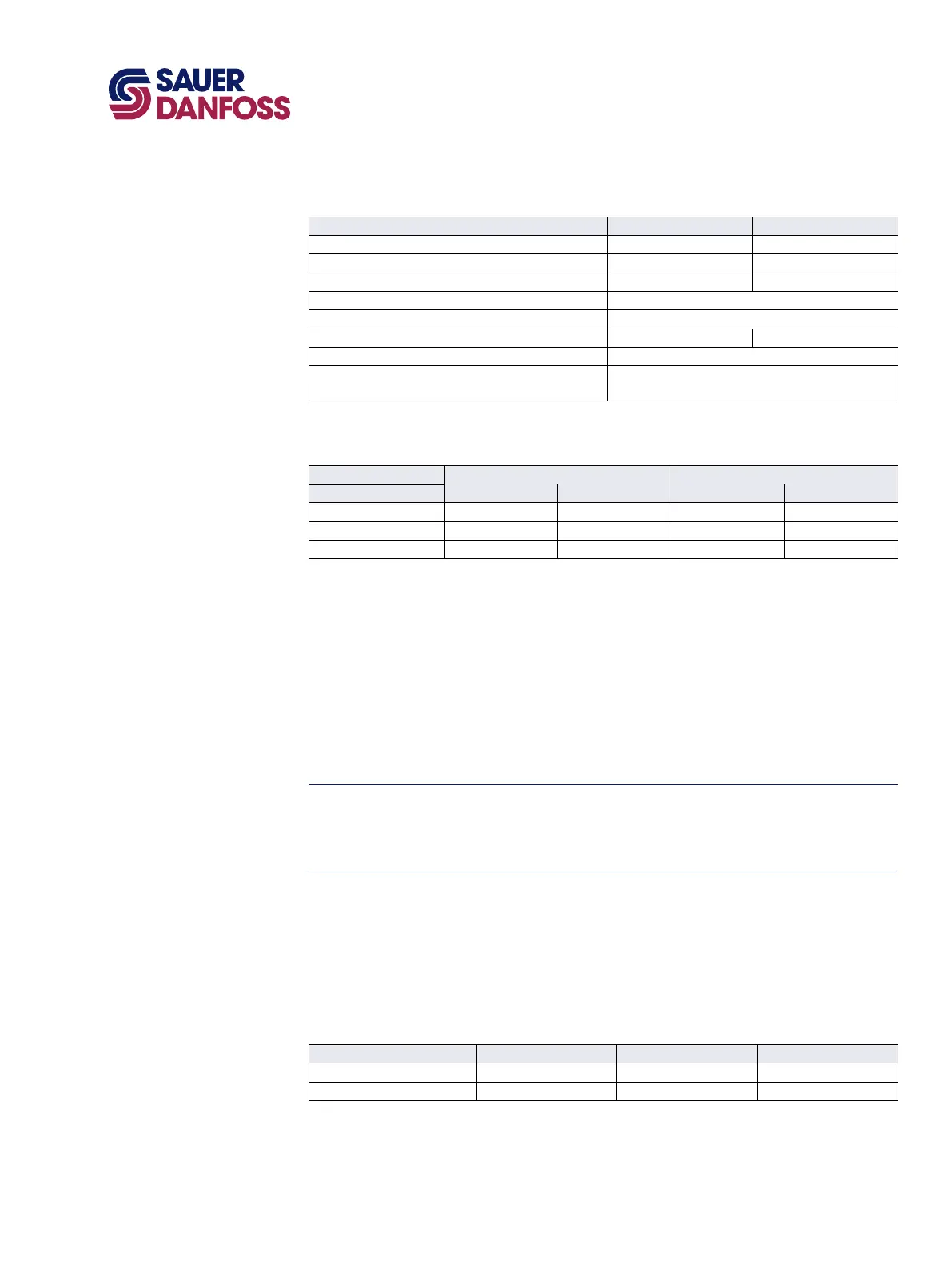

Solenoid data

Voltage 12V 24V

Maximum current 1800 mA 920 mA

Coil resistance @ 20 °C [70 °F] 3.66 Ω 14.20 Ω

Coil resistance @ 80 °C [176 °F] 4.52Ω 17.52Ω

PWM Range 70-200 Hz

PWM Frequency (preferred)* 100 Hz

Inductance 33 mH 140 mH

IP Rating (IEC 60 529) + DIN 40 050, part 9 IP 67

IP Rating (IEC 60 529) + DIN 40 050, part 9

with mating connector

IP 69K

* PWM signal required for optimum control performance.

T000 135E

Loading...

Loading...