www.scheppach.com

46

|

GB

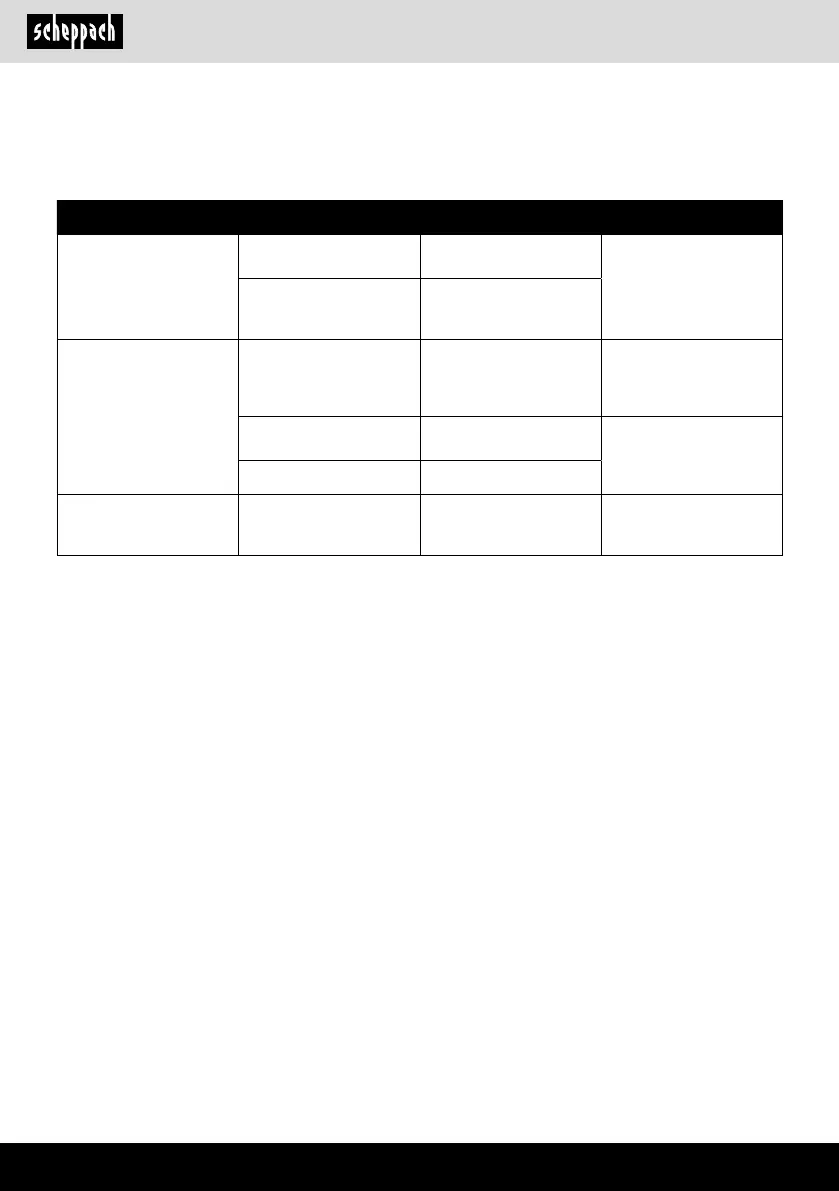

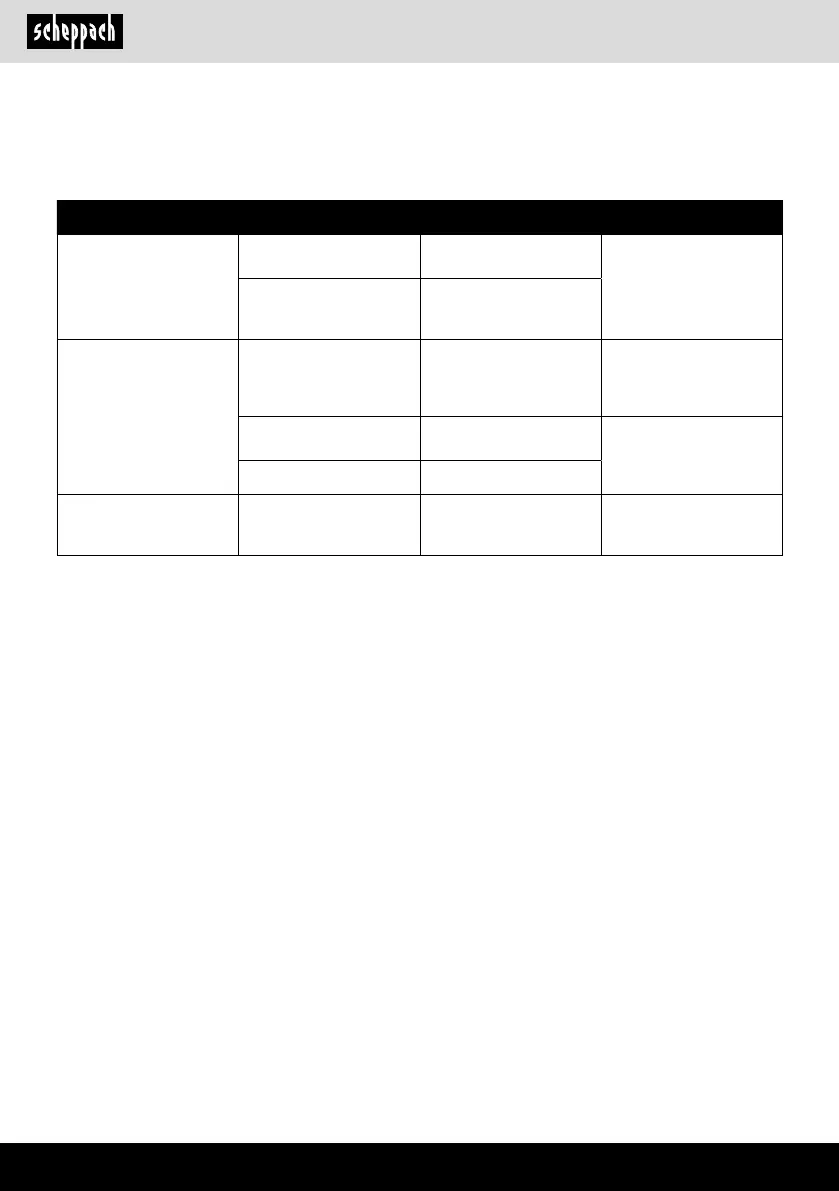

15. Troubleshooting

The following table shows fault symptoms and describes remedial measures in the event of your machine failing to

work properly. If you cannot localise and rectify the problem with this, please contact your service workshop.

Fault Possible cause Solution Danger level

The hydraulic pump does

not start

Voltage absent Check whether the lines

have power supply

Danger of electric shock

This operation must be

carried out by a mainte-

nance electrician.

The thermal switch of the

motor has switched off

Turn the thermal switch

inside the motor housing

back on

The column does not

move downwards

Low oil level Check the oil level and

top up

Danger of pollution

This operation can be

carried out by the machine

operator.

One of the levers is not

connected

Check the fastening of the

levers

Danger of cuts

This operation can be

carried out by the machine

operator.

Dirt on the rails Clean the column

Motor starts but the

column does not move

downwards

Wrong direction of rotation

of the motor with three-

phase current

Check and change the

direction of rotation of the

engine

Maintenance and repairs

All maintenance tasks must be performed by qualied personnel in strict observance of the present usage instruc-

tions. Prior to each maintenance task, all possible precautionary measures must be taken, the motor switched off

and the power supply disconnected (pull out connector). Attach a sign to the machine explaining the failure situation:

“Machine out of service for maintenance. It is prohibited for unauthorised persons to be at the machine and to start

it up.”

Loading...

Loading...