Operation

Startup 250:Users:Danny:Desktop:Operation manuals:line pumps:maverick

(P305):pHseriesOPERATION.fm

27

Operation Manual - SP 305

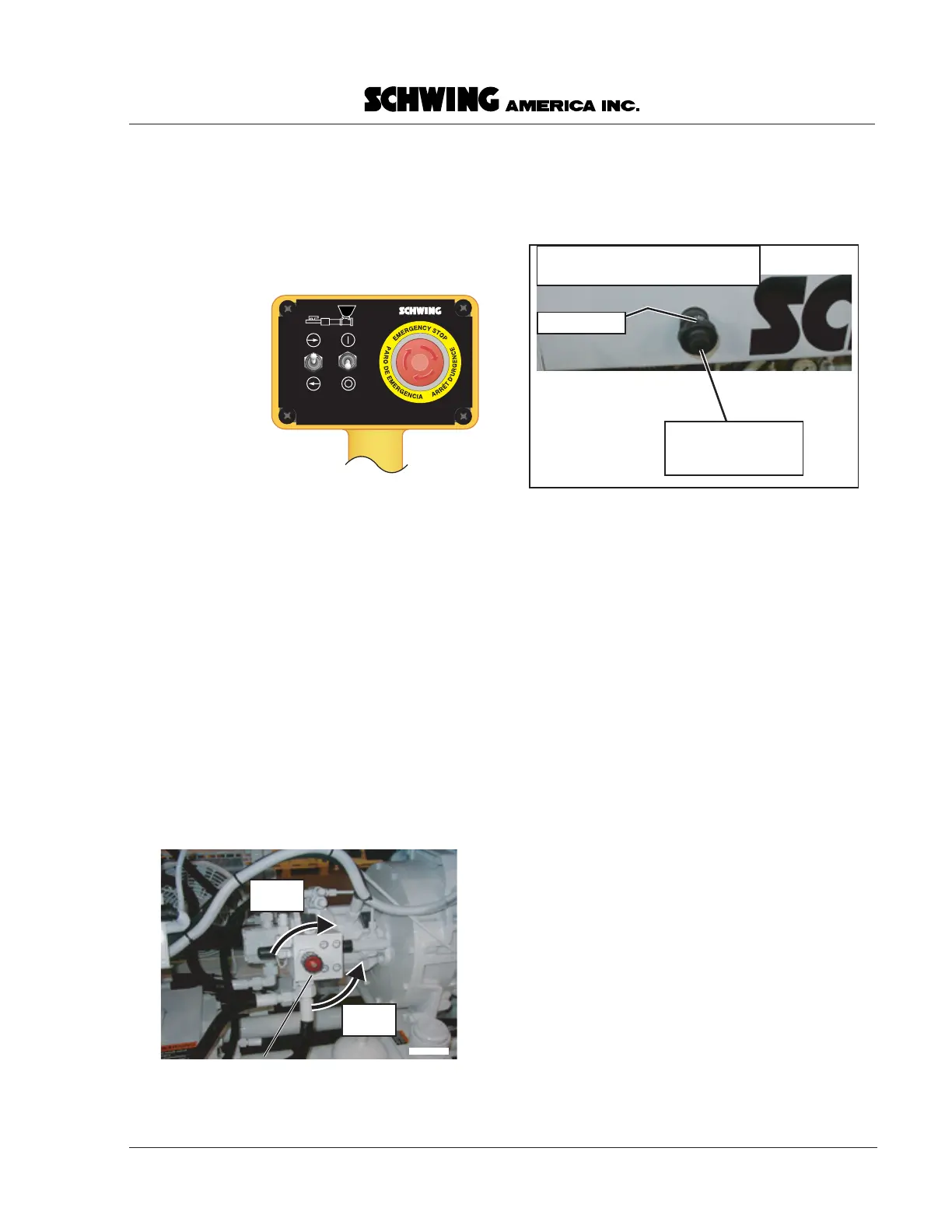

The remote control box

The cable remote control box (Figure 13) transfers the

forward - off - reverse

functions of the control panel

to a handheld electrical enclosure. The remote control

can be carried away from the pump to allow the

operator to select the best vantage point to see both the

point of discharge and the pump.

Note about the electric system

• The machine cannot be operated unless either the

dummy plug or the remote control cable is plugged

into the remote control cable receptacle on the

control panel. The emergency stop circuit is

completed by either device.

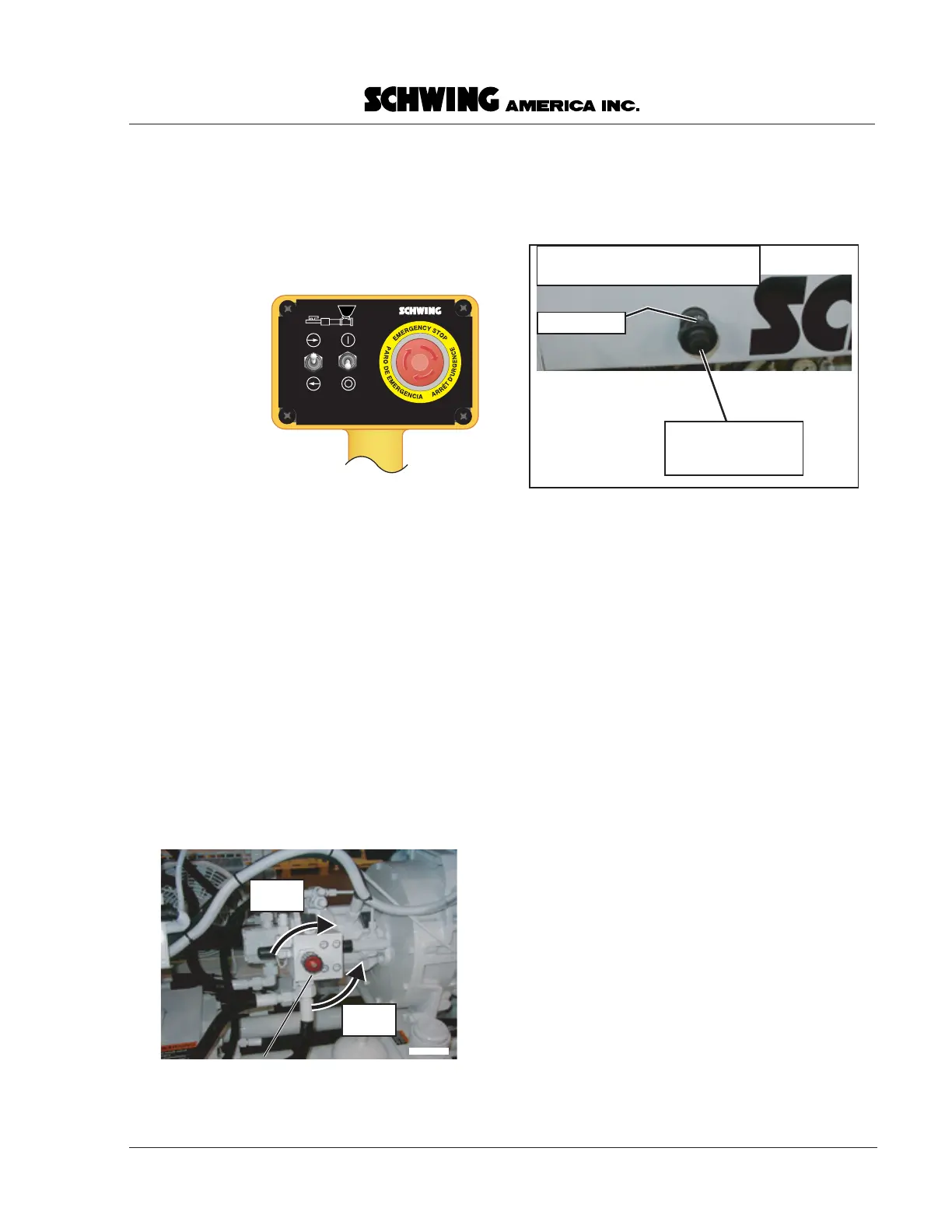

The volume control knob

(Also known as the stroke limiter) (Figure 14). This

knob tells the hydraulic pump to put out more or less

oil (independent of the motor speed) to control the rate

of concrete output.

Turning the knob

clockwise

(CW) causes less oil and,

therefore, less strokes per minute.

Turning the knob

counterclockwise

(CCW) causes the

pump to put out more oil and, therefore, more strokes

per minute.

Throttle control

Push the button on the end of the knob (Figure 15),

then pull the knob and cable

out

to increase RPM. Push

the button on the end of the knob, then push the knob

and cable

in

to decrease RPM.

The pressure gauge

This gauge indicates pressure in the hydraulic circuit

that pushes the concrete and includes the accumulator.

NOTE! Because accumulators store hydraulic energy,

it is critical that this gauge work at all times.

Do not

operate the unit unless this pressure gauge is

functional!

Starting the Pour

Concrete mixes

This machine is capable of pumping many different

mix types, up to and including one inch rock, but the

mix must be graded with some components in all of the

different sieve sizes. Generally speaking, any durable,

good quality concrete will pump. If you have trouble

pumping a mix, look at the mix design. Sieve sizes #4,

#8, and #16 must be present for the concrete to have

good pumping characteristics.

Preparing for concrete

When concrete arrives on the job, have the ready-mix

driver discharge a small amount of concrete onto the

chute so you can look at it. The concrete should be well

mixed, meaning that you won’t see just large rocks or

remboxonly.eps

30362341

Figure 13

The cable

remote control

box

volumeknob.eps

Volume control knob

(stroke limiter)

Less

strokes

More

strokes

Figure 14

The volume control knob

THROTTLE

Pull cable OUT to increase RPM,

push IN to decrease RPM.

throttle.eps

Friction ring

Using your thumb,

push button on end

of knob to release

Figure 15

Adjusting the throttle

Loading...

Loading...