Maintenance

Startup 250:Users:Danny:Desktop:Operation manuals:line pumps:maverick

(P305):pHseriesMAINTENANCE.fm

41

Operation Manual - SP 305

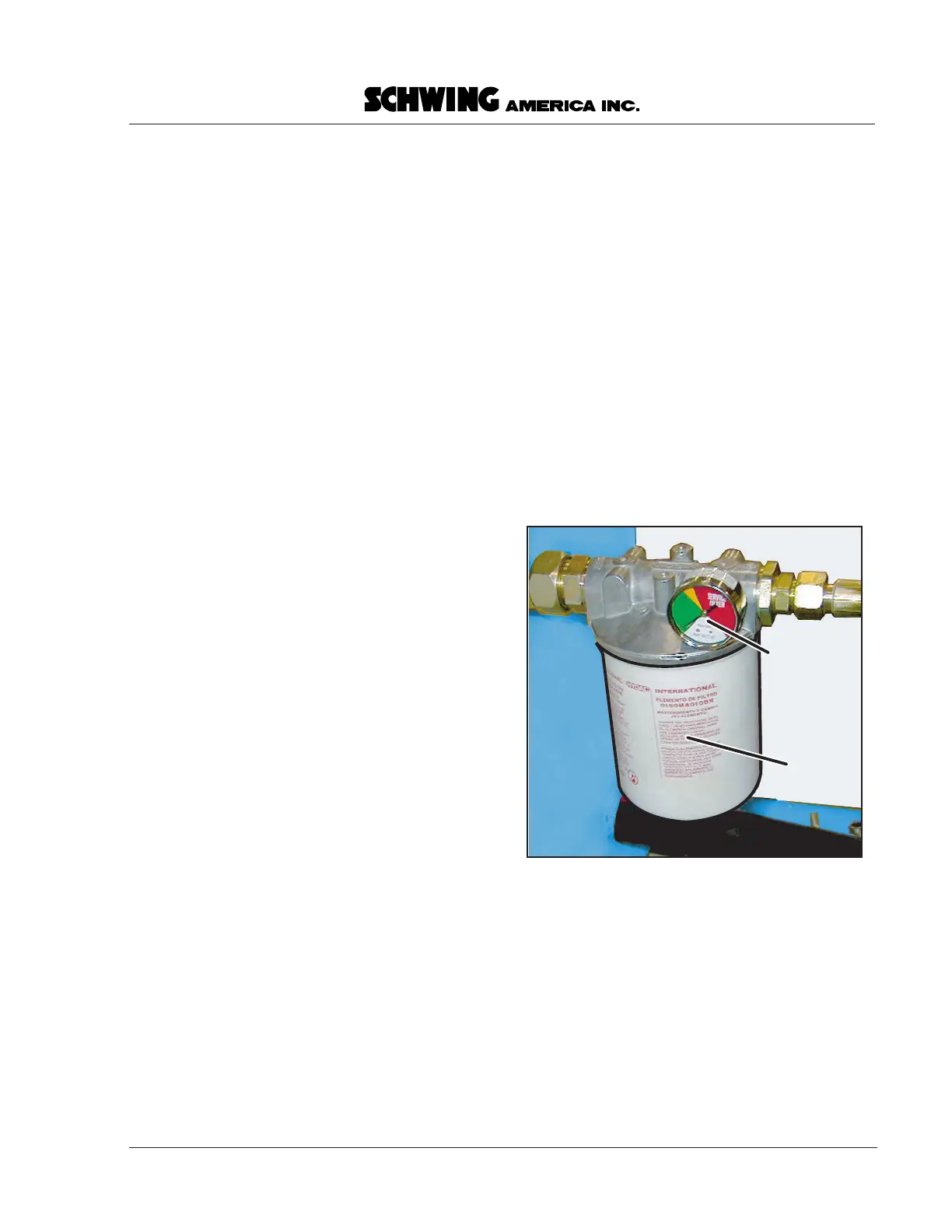

• The model SP 305 is equipped with a recirculation

type of filtration system, meaning that there is a

pump that sucks oil from the reservoir, pumps it

through the filter and cooler, and back to the tank.

Whenever the engine is running, oil is being

filtered. The filtration is done with a spin-on filter

assembly (Figure 28). It is equipped with an

integral bypass check valve set at 30 PSI. The

bypass valve protects the filter element from

damage, as explained below. The assembly is

equipped with an anti-back-flow check valve,

which prevents oil from draining out of the tank

while you are changing the spin-on element. There

is a dirty filter indicator to tell you when the

element is dirty. You should replace the element

whenever the indicator enters the yellow area and

the oil is heated above 20 degrees Celsius. Under

normal circumstances, the element will need

replacement about every 6 months. The element

has been designed to remove all particles large

enough to cause undue wear and jobsite

breakdowns (beta 10 = 200). You can keep the

hydraulic system running year after year by

replacing the element when replacement is due. Do

not substitute “will fit” elements in this housing.

Bypass Check valve

The filter is equipped with an integral bypass check

valve with a 30 P.S.I. pressure-to-open rating. This is

what it does:

When the filter is clogged with dirt and oil is having a

hard time making it through, the pressure difference

between the filter inlet and the outlet rises. This

pressure difference (commonly referred to as a

pressure differential) is called delta P and is shown as

ΔP. When the ΔP reaches 30 PSI, the check valve opens

and the oil returns to the tank unfiltered. If the filter did

not have the bypass check valve, it would simply break

apart when it was clogged. That could cause the filter

to fail in one of two ways:

1. All of the dirt ever trapped by the filter, plus the

filter itself, could go directly into the system.

2. Worse yet, the filter could split open and leak to

the ground, draining the reservoir, and

contaminating the environment.

Both potential problems are avoided by the bypass

check valve.

To change the element

1. Make sure the engine is shut off. Put the key in

your pocket to prevent someone else from

starting the engine.

2. Position a pan or bucket under the filter housing

to catch drips. The check valve built into the

filter, which prevents back flow, should not allow

much leakage oil, but there will be some. Oil

spills contaminate the environment.

3. Unscrew the filter element. Use an oil filter

wrench, if needed.

4. Remove the spin-on element, and pour the oil out

into the catch pan. Do not reuse this oil.

5. Remove the old element and replace with a new

element. Replace the bowl and tighten according

to the installation instructions that come with the

filter.

6. Start the engine, and check for leaks.

Hydraulic Oils

General information

Hydraulic oils are rated for viscosity, heat dissipation,

foaming characteristics, pour point, anti-wear

additives, anticorrosive additives, lubricating qualities,

compressibility, temperature range, temperature

stability, and other functions. Although many different

brands of oil will meet these specifications, they may

PHfilter.eps

Filter

Element

Dirty Filter

Indicator

Figure 28

The hydraulic oil filter

Loading...

Loading...