Maintenance

44

8/4/11

Operation Manual - SP 305

General Maintenance Tips

Torque specifications

When performing maintenance that requires removal

and replacement of bolts, it is very important to adhere

to the torque specifications that apply to that bolt

(Figure 30).

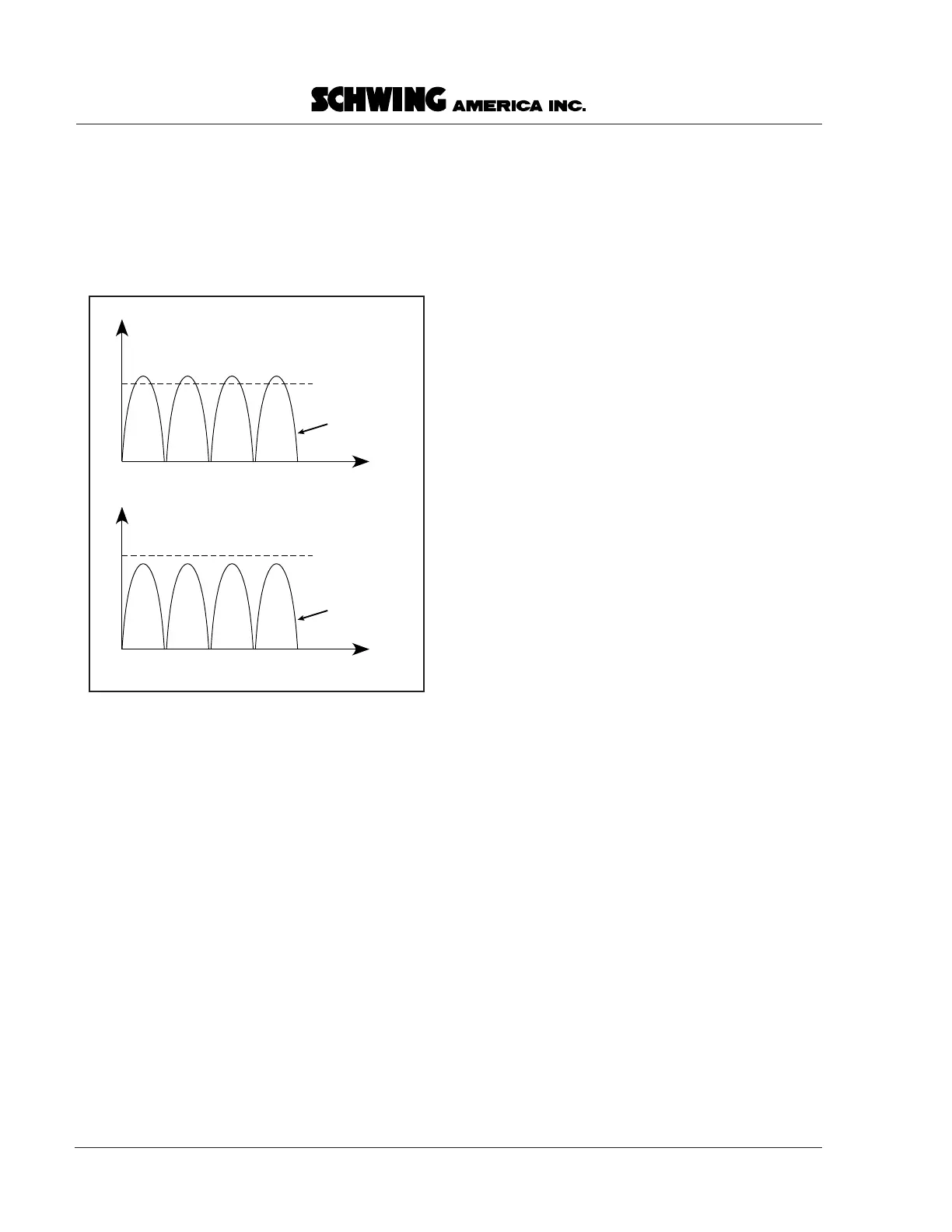

The graphs in Figure 30 demonstrate what happens to a

bolt if it is not properly torqued. The dashed line

represents the prestress on the bolt. As the device that

uses the bolt goes through its normal functions, the bolt

in example “A” gets stretched and relaxed with every

duty cycle, because the bolt is prestressed under the

maximum force of the cycle.

In example “B”, the prestress of the bolt has been

raised to more than the maximum force of the duty

cycle, so the bolt doesn’t ever feel the cycle. In this

example, bolt “B” would last MUCH longer than bolt

“A”. The torque specifications for bolts used on

Schwing equipment are found in the Appendix section

of this manual.

Adjusting relief valves

While adjusting a relief valve is not normally a

dangerous procedure, you should remember that it has

the potential to cause trouble. The main thing to watch

out for is this: Sometimes people who don’t know

better will have a problem with a machine and begin

troubleshooting by raising the pressure setting. When

that doesn’t help, they forget to lower it back down.

When you check the pressure by creating a hydraulic

block, the pressure is set too high. In extreme cases,

this can cause hoses or fittings to burst or other

component failure. To be safe, you should begin the

adjustment procedure by turning the adjustment device

to the lowest possible setting, then bring the device

back up to the proper setting.

Removal of safety devices

Sometimes you will have to remove a safety guard or

other safety device in order to perform maintenance.

For these situations, you must take extra care to be sure

of your own safety and that of your co-workers. If you

have to put your hands, feet or any other body part into

a part of the machine that would normally be guarded,

be sure that the machine is turned off and that the key is

in your pocket. If there is more than one key in

existence, you should also put a “DO NOT OPERATE”

sign on the controls or over the start switch.

Before restarting the machine after performing

maintenance, be sure to put away all tools, parts and

supplies, and clear the area of personnel. If your

company has a “lock-out, tag-out” policy in place,

abide by it.

Concrete pumps are big enough to hide a man. Be sure

to yell “clear” before starting the unit at any time, and

allow time for response before proceeding.

Time

Force

A

Time

Force

B

TorqueForce.eps

Prestress

Prestress

duty cycles

duty cycles

Figure 30

Effects of proper prestressing of a bolt

Loading...

Loading...