Appendix

SP 305

Startup 250:Users:Danny:Desktop:Operation manuals:line pumps:maverick

(P305):Appendix.fm

Operation Manual -

67

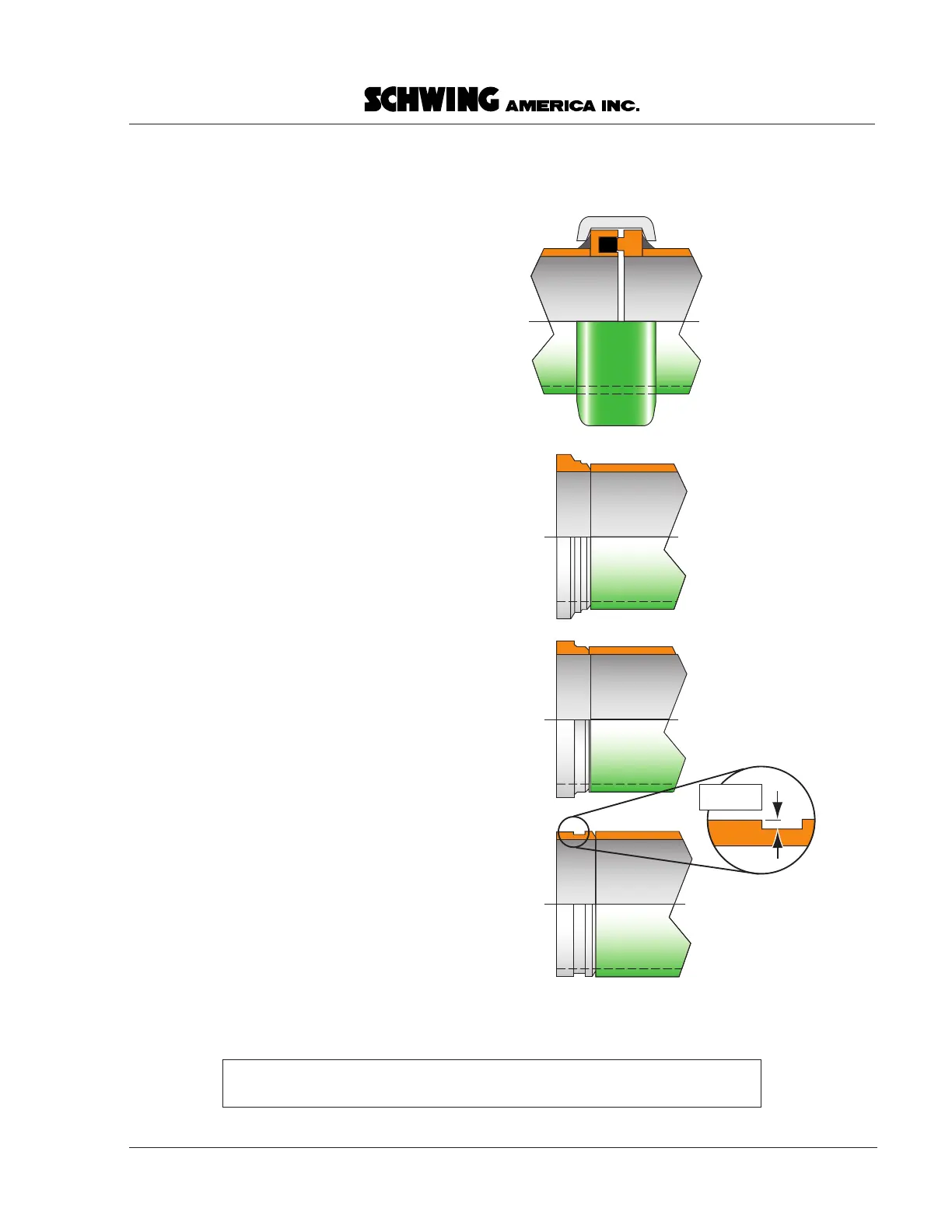

Weld-on Ends / Coupling Comparison

Heavy Duty

Metric

Grooved

(Victaulic)

Male / Female

O-Ring

(shown with clamp)

weldends4.eps

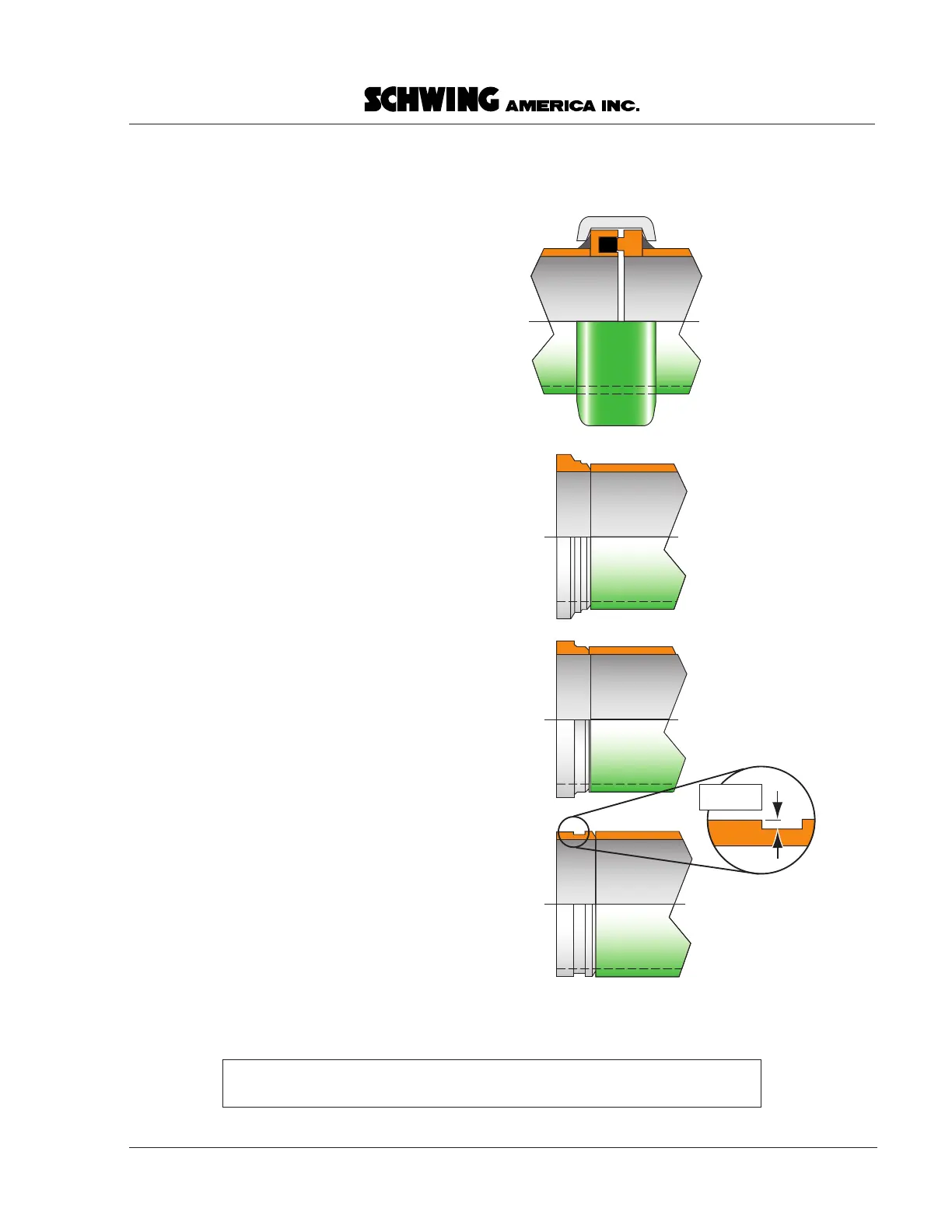

0.15"

NOTE: All pressure ratings listed refer to 5 inch (125mm) diameters

in like-new condition. Other pressures would apply to other sizes.

3. Metric couplings are designed for pressures up to

1400 PSI @ 2:1. They have 85% more contact area

than grooved couplings. The face is flat and will not

draw pipe together. Although they have a raised

edge, they are not compatible with Heavy Duty cou-

plings unless a special clamp or an adapter pipe is

used to change from one style to the other. Metric

connections are standard equipment on booms

because of the weight savings compared with other

styles.

2. Heavy-Duty couplings are designed for pressures

up to 2250 PSI @ 2:1. They have 20% more contact

area than metric couplings, and a tapered face that

draws the pipe sections together during assembly.

Both the ends and clamps weigh more than metric

style, and therefore should not be used on booms

without consulting the manufacturer.

1. Male / female o-ring type couplings have the

highest pressure rating of the ends commonly used

for concrete pumping. They can withstand 4350 PSI

@ a 2:1 safety factor. They are self aligning and

waterproof when used with o-rings in good condi-

tion. Typically not used on booms because of their

weight. Pipes equipped with this style coupling

cannot be swapped end-for-end.

4. Grooved couplings (lip height of 0.15” or less)

are designed for pressures only up to 750 PSI @

2:1. The recessed groove is hard to clean when

changing pipe on a job. The weld-on end fails

before the pipe because the groove is cut into the

pipe thickness, making it the weakest spot. Grooved

couplings are not recommended for concrete pump-

ing applications.

Shown is a comparison among commonly used

ends/couplings. No two ends shown can be joined

without the use of an adapter pipe or a special

adapter clamp. Clamps and pipe strength must also

be considered when determining proper system

requirements. The ratios shown in the text below

represent the safety factor from burst : working

pressures.

Loading...

Loading...