Appendix

Operation Manual -

SP 30582

revDate

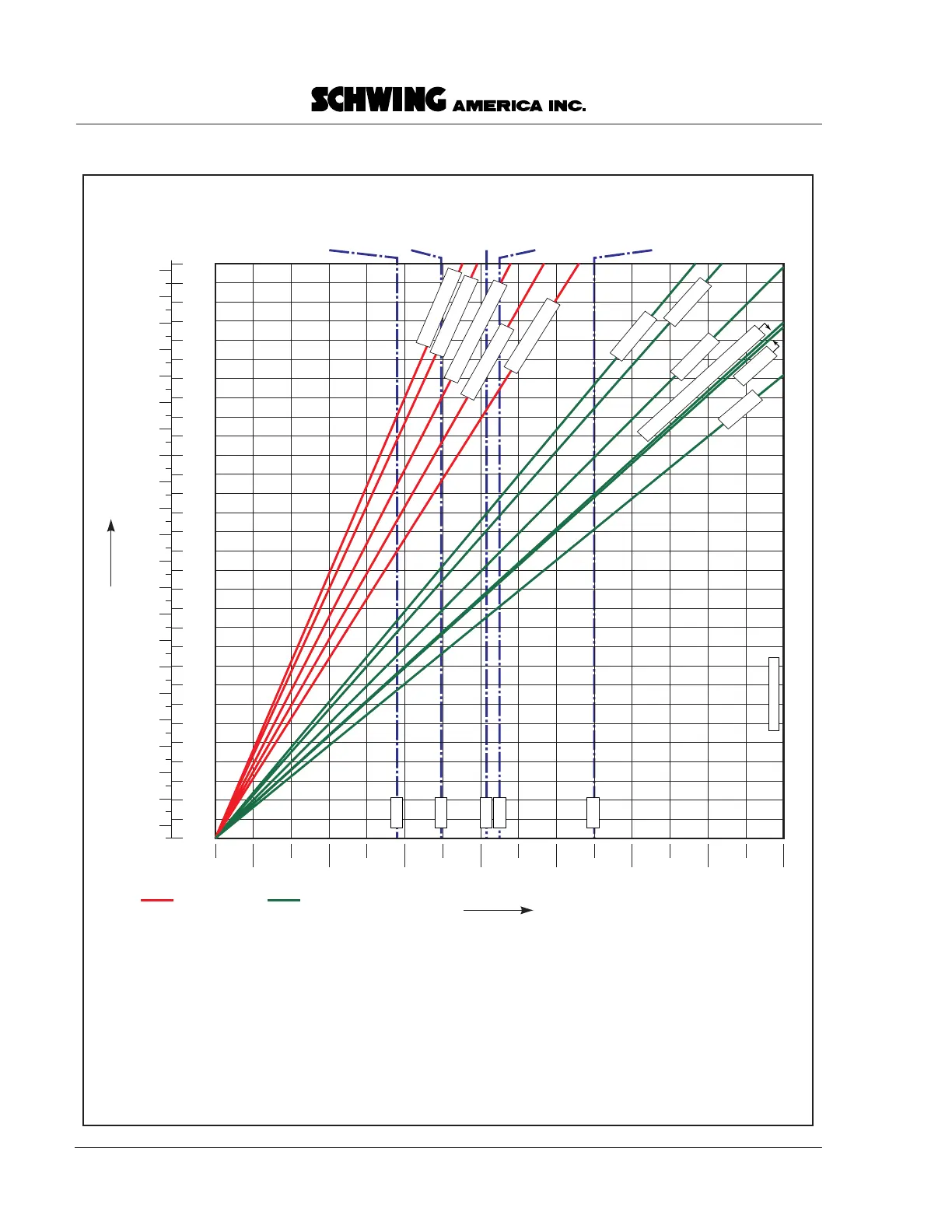

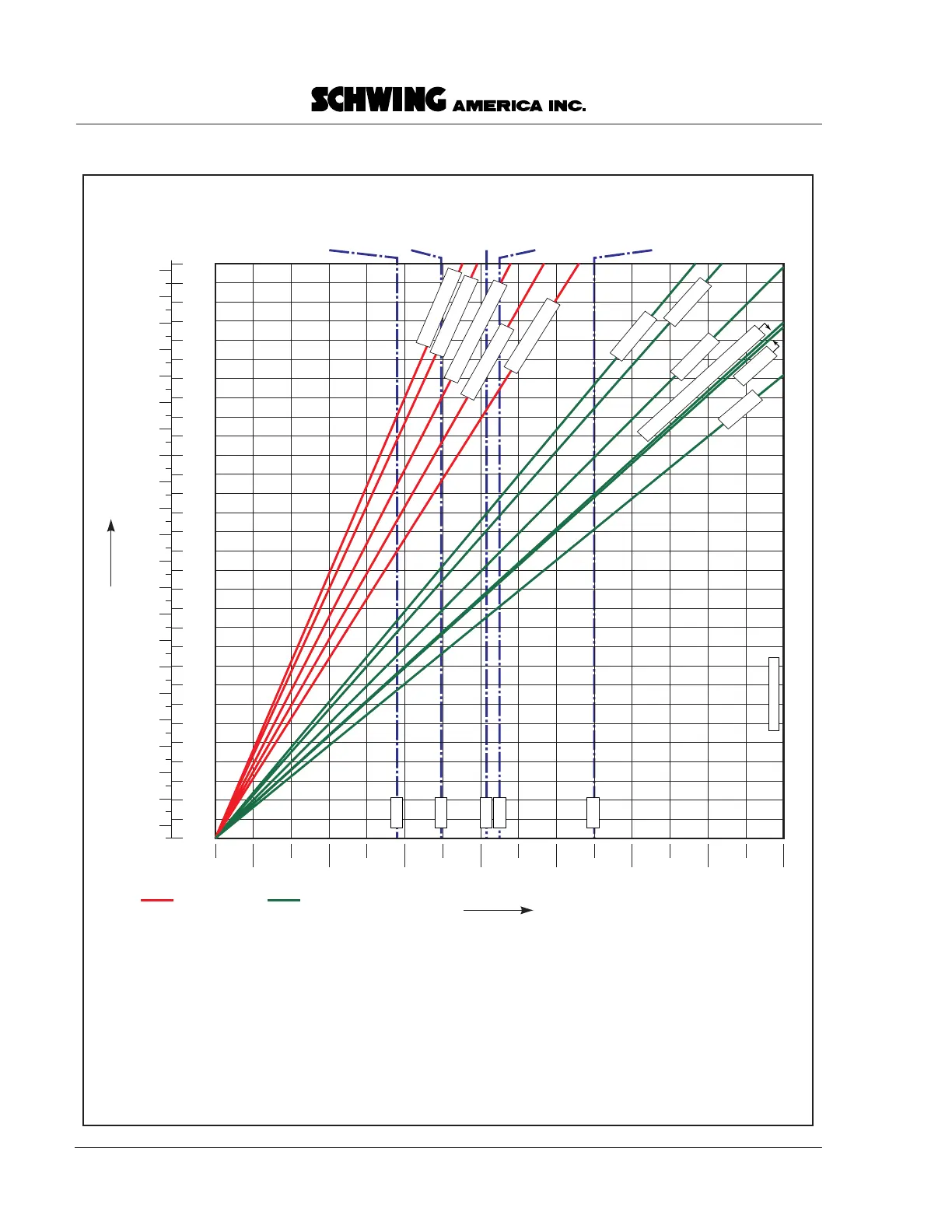

Minimum Pipe Wall Thickness

PIPE WALL THICKNESS

0

.025"

.050"

.075"

.100"

.125"

.150"

.175"

.200"

.225"

.250"

.275"

.300"

.325"

.350"

.375"

0

200

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

280

290

300

SCHEDULE 40

(1/4 wall)

9 gauge 3/16”

11 gauge 7 gauge

MATERIAL PRESSURE

BARPSI

1. This chart assumes a safety factor of 2:1. Higher safety factors may be required in some circumstances.

2. Wear reduces wall thickness. Thickness must be checked on a regular basis.

3. Pressures may be limited even more by clamp style or pipe end used.

4. The chart is based on 62,000 PSI tensile strength. Heat-treated calculations are based on 120,000 PSI tensile strength.

5. The chart is for pressure calculations ONLY. There is no allowance for mechanical forces other than pressure, and thicker

walls may be needed for mechanical strength because of support or restraint considerations.

6. The chart does not take into account metal fatigue caused by pressure cycles.

Note! This chart is intended as a guide for concrete pumping applications and is subject to the notes,

assumptions, and conditions listed above. Any other use of this chart is not recommended.

This chart does not apply to double-wall pipe. Double wall pipe can be checked by inspecting the inside of the pipe. If the insert is intact, the pipe is

okay. If the insert is worn through, the pipe must be replaced. Contact your pipe supplier for the pressure capacity of your double-wall pipe.

pipewallvsPress2.eps

.heat treated .standard

4“ HEAT TREATED

5“ HE

AT TREATED

6

“ HEAT TREATED

4.8” & 4.9“

HEAT TREATED

4.4” HEA

T TREATED

4.9“ (7, 9, 11

gaug

e) sys

te

m (125 mm)

6“ system

5“ system

4.0“ system

4.4“ system

4.8“ system

0.120”

0.150”

0.177”

0.188”

0.250”

Minimum Pipe Wall Thickness As a Function of Pressure

Loading...

Loading...