Operation

Startup 250:Users:Danny:Desktop:Operation manuals:line pumps:maverick

(P305):pHseriesOPERATION.fm

35

Operation Manual - SP 305

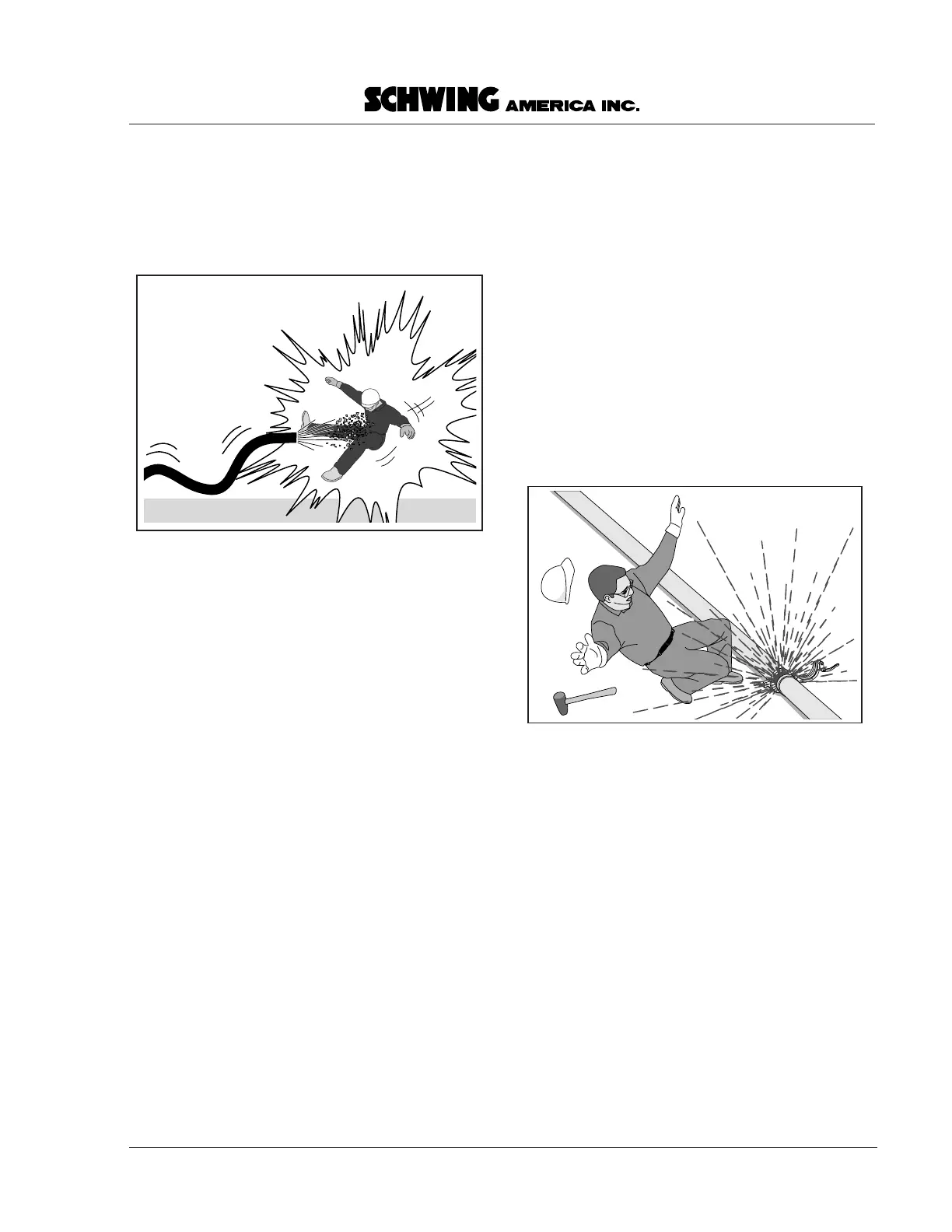

WARNING! Release of stored energy hazard

(Figure 26). If you are successful at rocking the plug

loose, air will be introduced into the line at the delivery

end. If a blockage would then form in front of the air,

the air would become compressed when you switch

back to forward pumping. Clear the discharge area of

personnel before rocking the plug.

To rock the plug: When the unit stops pumping,

immediately put the pump forward - reverse switch

into the reverse position. Pump in reverse for two

strokes. Put it back in forward and pump for two more

strokes. Put it in reverse for two strokes, then to

forward, etc. Sometimes this method dislodges the

plug. It is less likely that reversing the pump will help

dislodge a blockage in a longer pipeline, because the

suction you create at the pump doesn’t have enough

power to move a long horizontal line of concrete.

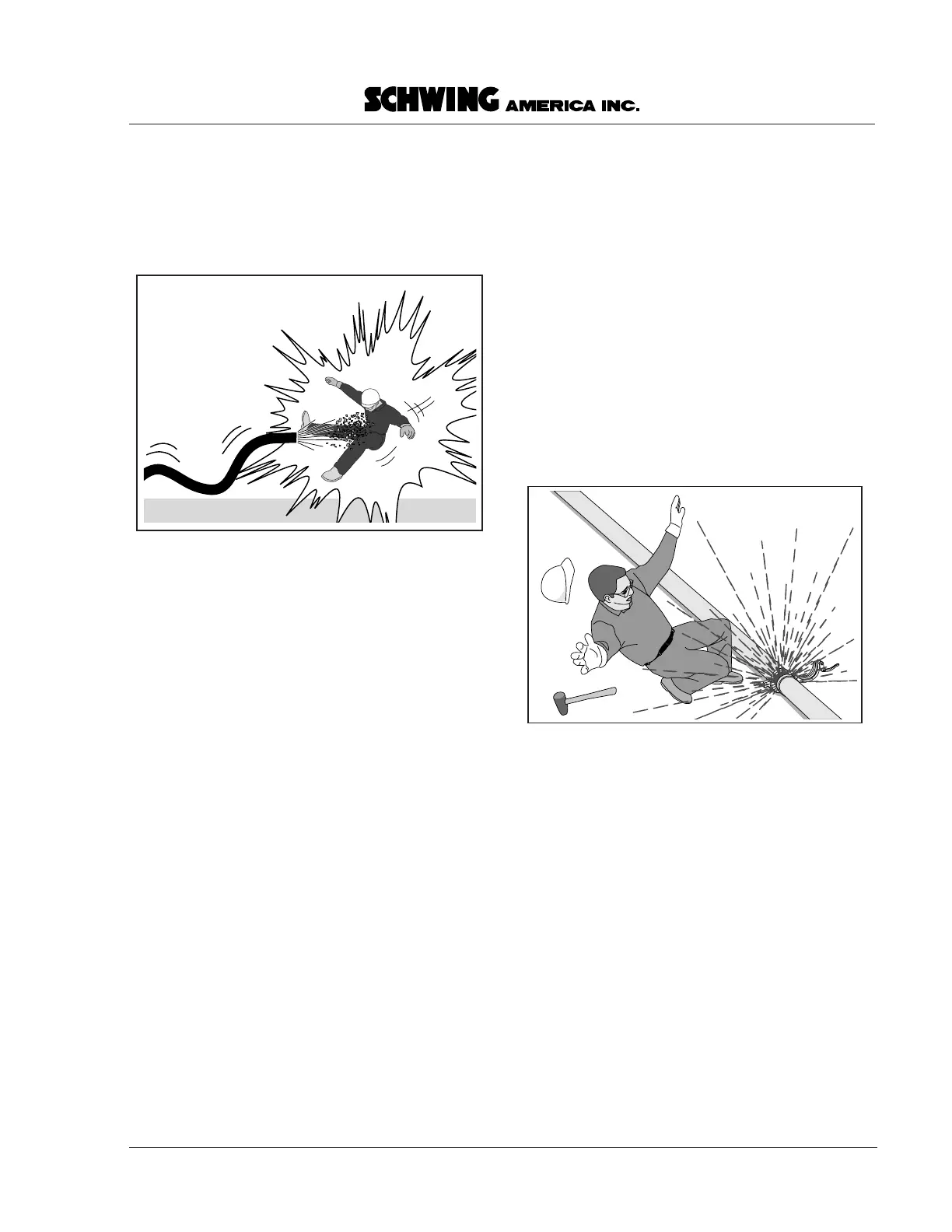

3. Remove the plug manually. If the above step

didn’t help, you will have to locate the plug and

remove it manually. Never open a delivery

system line that is pressurized! First, relieve

the pressure in the line by pumping in reverse

for at least two strokes. Locate the plug by

tapping on the line with a hammer. (NOTE! TAP

is the key word. If you hit the line too hard it will

dent. A dented line wears out at the dent

quickly.) When pressure is removed from the

line, it has a hollow sound, except for the plug,

which sounds solid. Reducers, elbows, and

rubber hoses are most susceptible to plugs, so

start by checking them. If you cannot locate the

plug by tapping, break the line at about the

halfway point. Clear the discharge area of

personnel, then try pumping in forward again. If

the machine still stops, the plug is in the half of

the line that is still connected to the pump. If

concrete comes out of the line where you

disconnected it, then the plug is in the half of the

line that was disconnected. Remember to

relieve the pressure on the line again before

breaking the line anywhere else! You can

locate the plug by the process of elimination if

you keep breaking the line in different spots and

trying to push concrete to the disconnected point.

When you locate the plug, remove it.

Reassemble the line, including the clamp

gaskets. NOTE: Air is introduced into the line

when you break it apart, so remember to clear the

discharge area of personnel before starting again.

Lower the volume control to stroke slowly until

concrete is running steadily.

Cold weather pumping

Keep these things in mind if you must pump at

temperatures below 32° F (0° C):

• Water freezes below 32°F, so cleanout must be

done with heated water.

• If concrete sits for too long, it freezes. When it

freezes, setting action stops. To prevent this, the

engineer will probably order the concrete with

calcium chloride or a similar chemical intended to

make the concrete set before it can freeze. This can

work against you if you take too long to clean out

or if you have to wait during the pour. Speed up the

cleanout process as much as possible without

taking risks.

Figure 26

Successfully rocking a plug loose

introduces air into the line

explode2.eps

Figure 27

Never open a pressurized delivery line

Loading...

Loading...