Maintenance

Startup 250:Users:Danny:Desktop:Operation manuals:line pumps:maverick

(P305):pHseriesMAINTENANCE.fm

45

Operation Manual - SP 305

Preventative Maintenance

NOTE!

There is a sample maintenance chart shown

in this section of the manual, page 57.

Daily maintenance

1. Check the levels and condition of the lubricants

and coolant in the towing truck. Follow the

manufacturers recommendations for quantity

and type.

2. If the towing vehicle has air brakes, bleed the

moisture out of the truck air system by opening

the pet cocks located on the bottom of the air

tanks. This is especially important if there is a

chance that the moisture will freeze.

3. Check the condition of the tires on both the

towing truck and the trailer. Do not drive the unit

with bald, cracked or damaged tires.

4. Check the level and condition of the hydraulic oil

(Figure 31). Top up, if necessary, with the same

brand and type of oil. If you have a filter buggy

to pump oil into the tank, use it. Replace milky

looking oil, which is a sign of water

contamination. Try to determine the source of the

water, if possible. If the oil has turned milky

quickly, like from one day to the next, then just

replacing the oil will not solve your problem, and

the new oil may be milky looking the next

morning. If you need help with ideas of where to

look for the source of water contamination, call

Schwing America’s Service Department at (651)

429-0999.

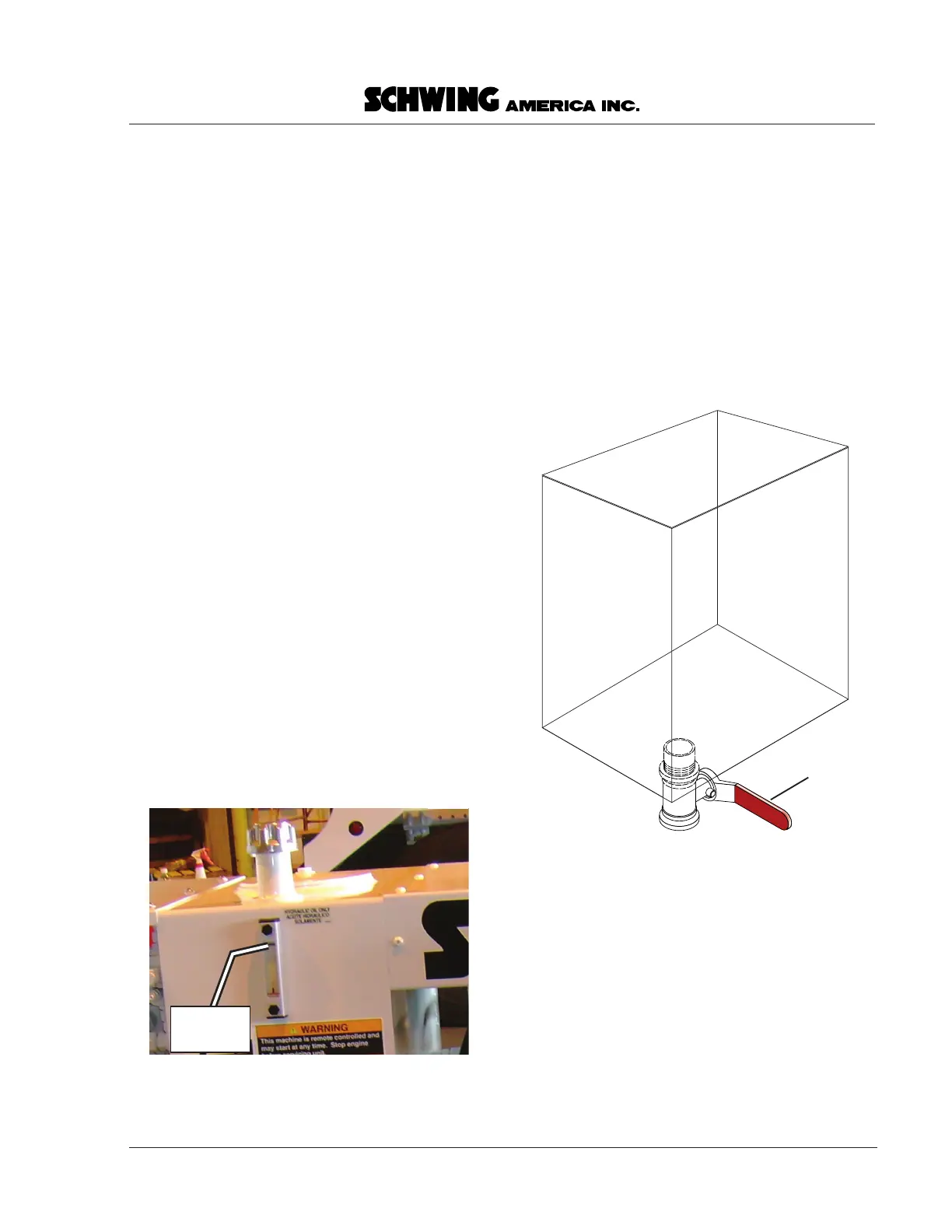

5. Bleed the water out of the bottom of the

hydraulic oil reservoir by opening the drain cock

or faucet located at the bottom of the reservoir

(Figure 32). Place a drain pan under the outlet

hose, open the valve, and watch the liquid as it

leaves the hose. When the liquid changes from

water to oil, close the valve. Because of

condensation, which is aggravated by large

heating-cooling cycles, it is normal that there

will be a small amount of water in the tank every

day, but it should settle to the bottom of the tank

overnight. The water that is drained should be

clear, and the oil that follows it should also be

clean, not milky.

6. Check the differential cylinder rod packings for

wear by filling the waterbox with water above

the level of the differential cylinder rods (if no

grate is installed) or above the bolt down grates

(if installed). Let it sit for a few minutes. If oil

begins to float to the top of the water, it is an

indication that the rod packings are worn. (Oil is

lighter than water, and will float.) Don’t forget to

Figure 31

The hydraulic oil level indicator

Oil Level

Indicator

OilLEV.eps

tankdrain.eps

Drain cock

Figure 32

The drain cock used to drain water

from the reservoir

Loading...

Loading...