Maintenance

Startup 250:Users:Danny:Desktop:Operation manuals:line pumps:maverick

(P305):pHseriesMAINTENANCE.fm

43

Operation Manual - SP 305

• If you lower the pressure at which the system runs,

you can defeat the power of the system. For

example, you ask the machine to develop 2400 PSI

hydraulic pressure to push the concrete where you

want it to go. You want to replace a hydraulic hose

with a less expensive, lower pressure hose, so you

lower the hydraulic pump pressure setting from

2500 PSI to 1500 PSI. What is the result? The

concrete still requires 2400 PSI to get where you

want it, but your pump can only put out oil up to

1500 PSI. Now the oil that should be pushing the

concrete is instead telling the hydraulic pump to

stop putting out oil. Nothing moves, and your

concrete pump has been rendered useless by a

cheap hydraulic hose.

• If you raise the pressure at which the system runs,

you can harm the system. Using a new example,

the concrete requires that the machine develop

2900 PSI hydraulic pressure to push it where you

need it. Your machine is factory set to run at a

maximum of 2500 PSI, so you raise the setting of

the pump compensator to do the job. The hydraulic

pump can’t withstand 2900 PSI for more than a

few minutes, and it breaks. You now have to

replace a pump before you can make another pour.

• If you leave the machine at the factory

specification, you DO NOT harm the system. It

gives you years of dependable service. This means

you should only use fittings and hoses that have a

sufficient WORKING PRESSURE to handle the

system requirements. If you take a job that needs

more pressure than your machine has, you should

buy or rent a higher pressure machine.

Specific Information

• Schwing uses high pressure fittings and hoses on

all circuits, even if the relief valve for that circuit is

set to low or medium pressure. The fittings and

hoses are rated at a minimum of 5000 PSI working

pressure, and in the case of some fittings, up to

15,000 PSI. We advise against changing any circuit

to lower rated hoses or fittings.

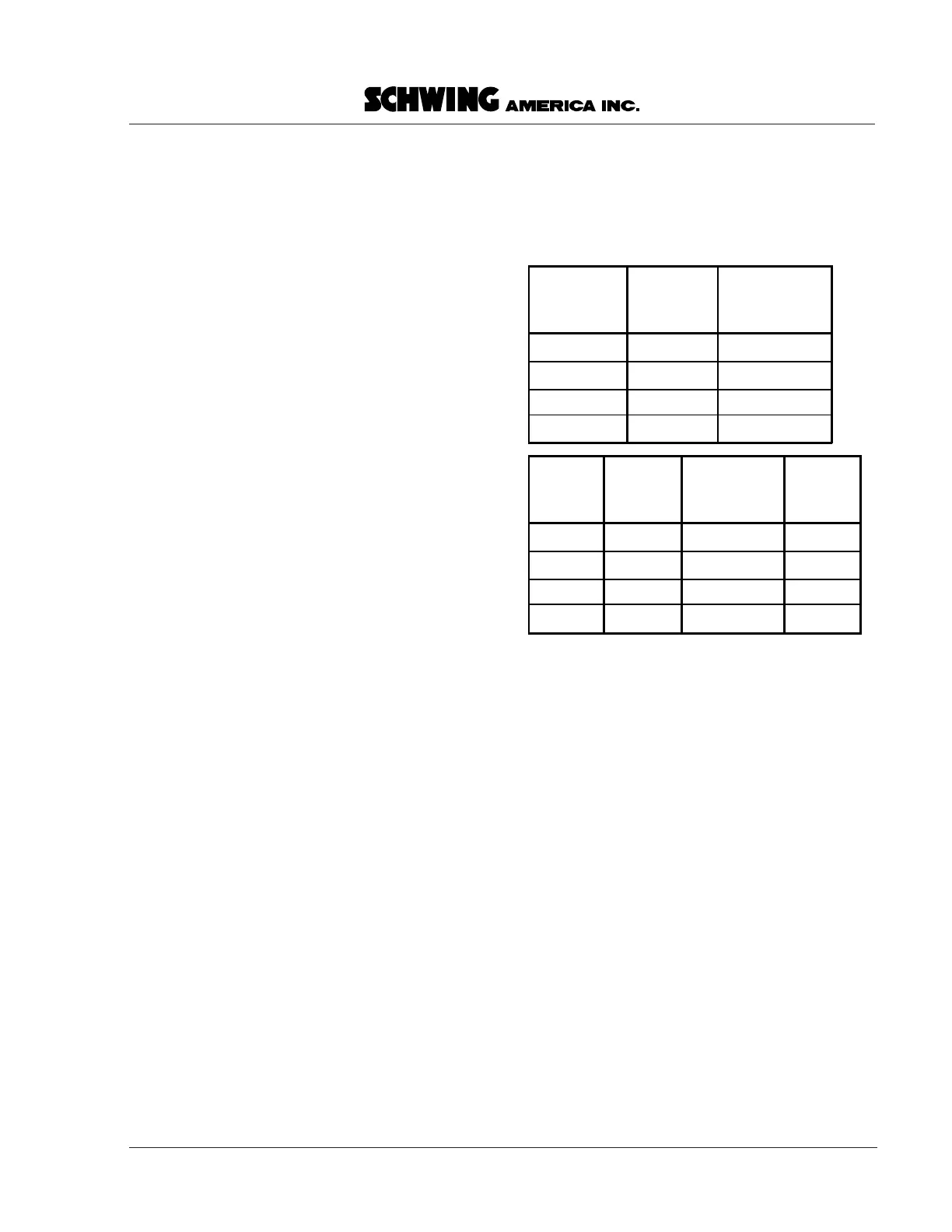

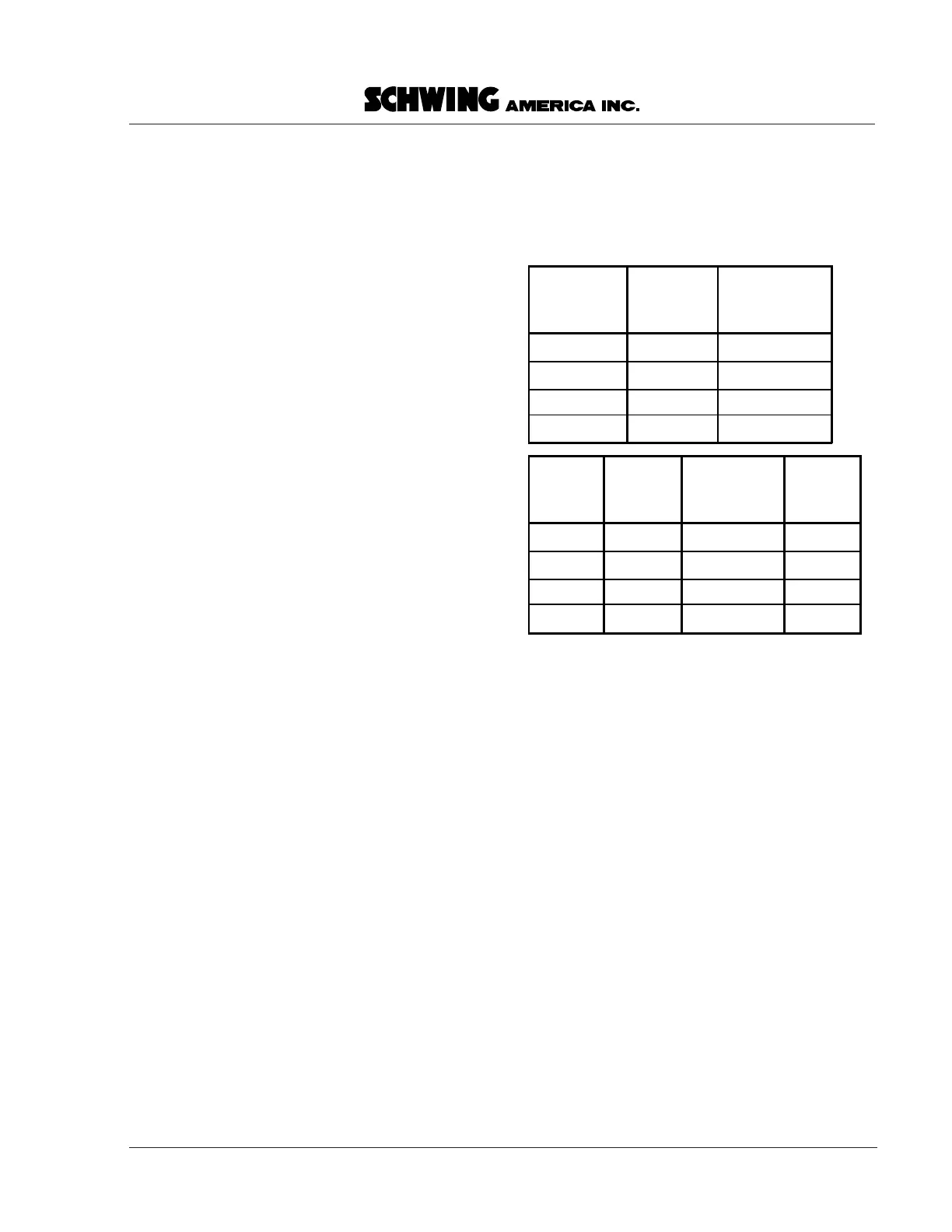

• We use metric fittings and hoses, with metric

threads on the couplings. There are four diameter

sizes of tubes and fittings used on this unit and four

diameter sizes of hoses. The chart in Figure 29 tells

you what the sizes are and what they will attach to.

• All block threads are metric or BSPP.

• Instructions for setting the relief functions are

shown in the preventative maintenance section of

this manual.

Hose Size Hose I.D.

8 8 mm

13 13 mm

16 16 mm

20 20 mm

Connects

with Fitting

& Tube Size

12

16

20

25

12

16

20

25

Tube &

Fitting

Size

8

13

16

20

Connects

with

Hose Size

Tube &

Fitting

O.D.

12 mm

16 mm

20 mm

25 mm

Tube &

Fitting

I.D.

8 mm

13 mm

16 mm

20 mm

1COLPhoseFITTING.eps

Figure 29

Hose, fitting and tube sizes versus

connection sizes

Loading...

Loading...