Appendix

SP 305

Startup 250:Users:Danny:Desktop:Operation manuals:line pumps:maverick

(P305):Appendix.fm

Operation Manual -

77

less than maximum pressure.

Maximum pressure (abbreviated as max P) is

determined by the size of the differential and material

cylinders and the setting of the main relief valve. To be

sure that the unit will handle the job, be careful to

notice max P and max Q. Here is an example of why

that is important: You contract to pump a job that

requires only 20 yards per hour, but you calculate that

you will need 2100 PSI pressure. The PF of this job is

42,000 (20 x 2100). The pump shown in Figure 51 has

a TK of 72,600, so there is enough power available.

However, the maximum pressure available from the

pump is only 1570 PSI. This pump would not do the

job.

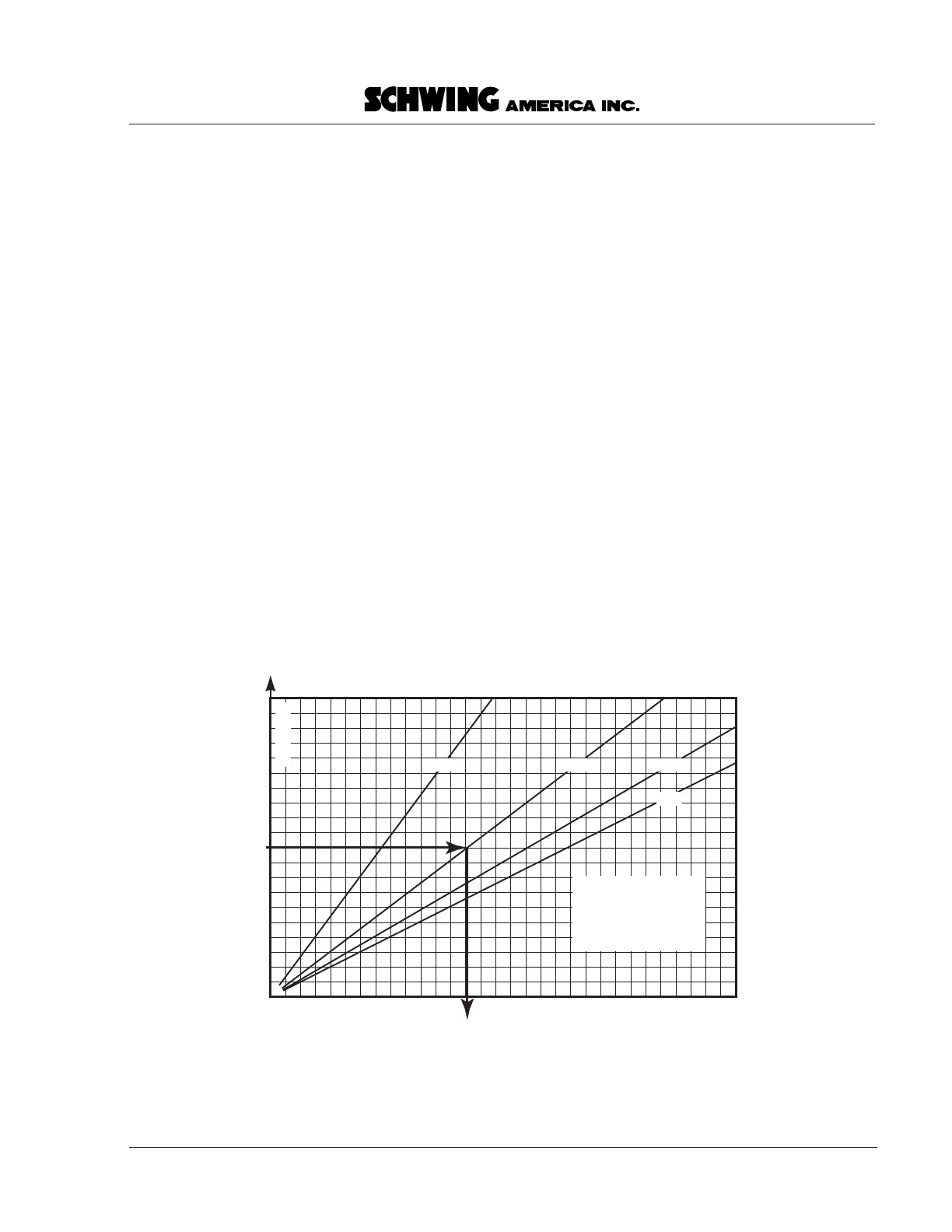

2. Follow the chart in a straight line from required

output into the upper right quadrant until you

come to the size of the pipeline that you will use. A

good rule of thumb for sizing pipeline is to use the

largest diameter pipeline that you can. It takes less

force to move concrete through a 6-inch pipeline

than, for example, a 4-inch pipeline. When

pressure is exerted on concrete in a pipeline, a

paste of water and cement fines coats the inside of

the pipeline and forms a slippery layer on which

the bulk of the concrete slides. While it is true that

a 6-inch pipeline has 49 percent more surface area

to coat than a 4-inch pipeline, the volume of

concrete that can move on the layer is increased by

125 percent, which results in lower velocity of the

concrete (in feet per second), lower friction, and,

therefore, lower pressure. A pump that may not be

capable of completing a difficult job through 4- or

5-inch pipe may be able to do it easily through 6-

inch pipe. Note! Experience has taught us that 5-

inch is the optimum pipeline size for lengthy

vertical runs, such as those found on high-rise

buildings. It is large enough for most aggregate but

small enough that you minimize the amount of

concrete that slides back into the hopper when the

concrete valve cycles, which we call backwash.

You must also consider the people at the point of

placement. Very few hose handlers, if any, can

move 6-inch hose on a slab all day. There is no

provision in the nomograph for mixing pipeline

sizes. For example, if you will be reducing from 5-

inch to 4-inch pipe, you should calculate the chart

as if you were using 4-inch pipe for the entire

distance. This will not be completely accurate, but

you will be safe in your pressure calculation. In our

example, we use 5-inch pipeline (Figure 52).

Q in yd

3

/hr.

Pipeline diameter in inches

6" 5" 4.5"

4"

000023.eps

Make a 90˚ turn when

you intersect with the

pipeline diameter that

applies to your job.

Figure 52

Upper right quadrant—Pipeline diameter

Loading...

Loading...