13

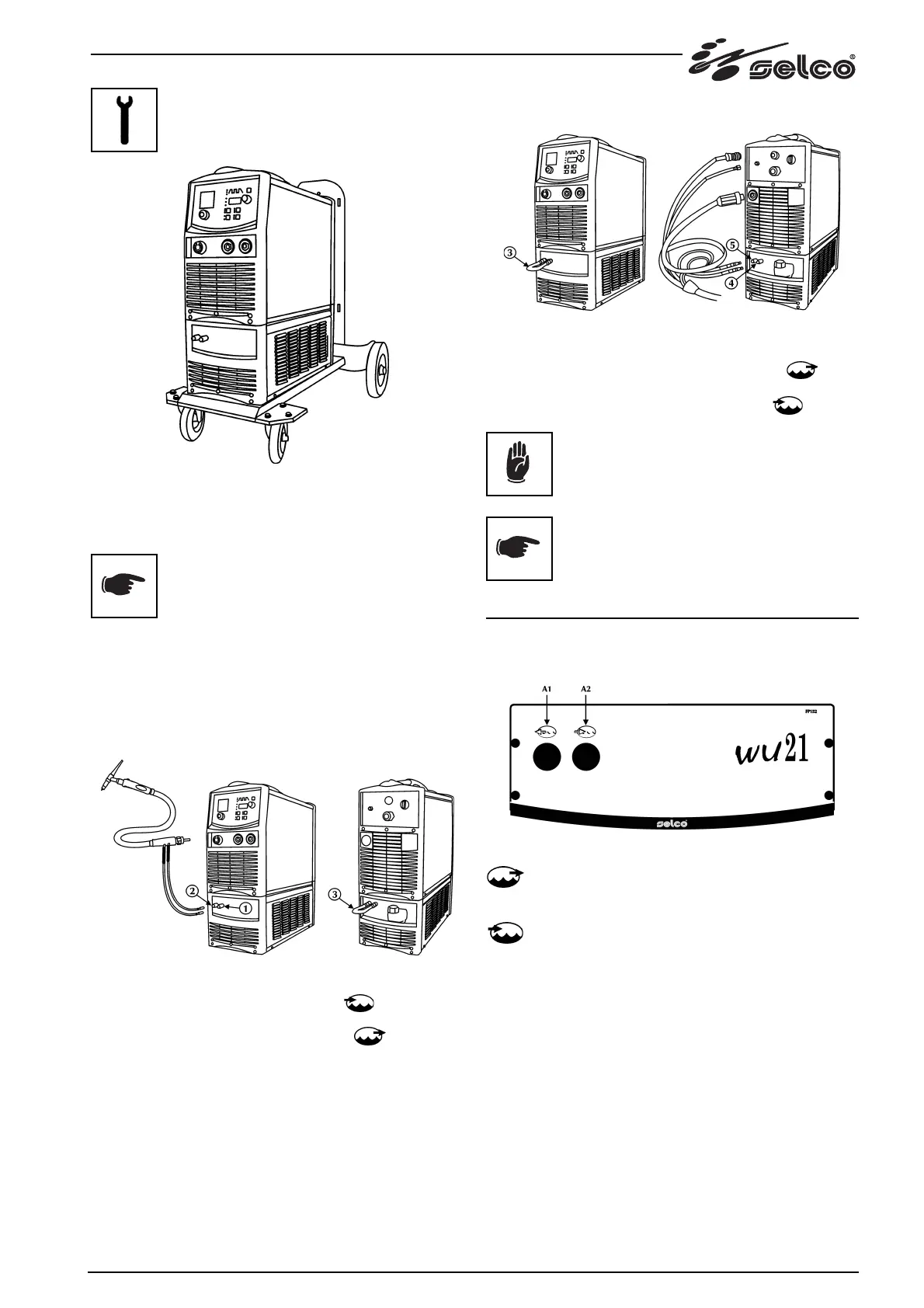

2.4 Installation

- Put the WU on the GT and block it with the 4 screws.

- Position the power source above the cooling unit and secure

it by means of the screws.

Perform the following operations before starting

the unit:

- Remove the refill neck cap.

- Remove the sealing cap from the refill neck, levering by

means of a tool on the edge of the cap.

- Fill the tank with cooling liquid if necessary.

- Keep apart the sealing cap for future transport of the unit.

Connection for TIG welding

- Connect the red hose of the torch to the appropriate inlet

quick connector (1) (red colour - symbol

).

- Connect the blue hose of the torch to the appropriate outlet

quick connector (2) (blue colour - symbol

).

Connection for MIG/MAG welding

- Connect the blue hose of the cable bundle to the appropriate

outlet quick connector (4) (blue colour - symbol

).

- Connect the red hose of the cable bundle to the appropriate

inlet quick connector (5) (red colour - symbol

).

In order not to damage the cooling unit, always

fit the by-pass pipe (3) when the torch is not con-

nected to the cooling liquid inlet/outlet termi-

nals.

Filling or topping up of the tank must be per-

formed with cooling liquid, code 18.91.001.

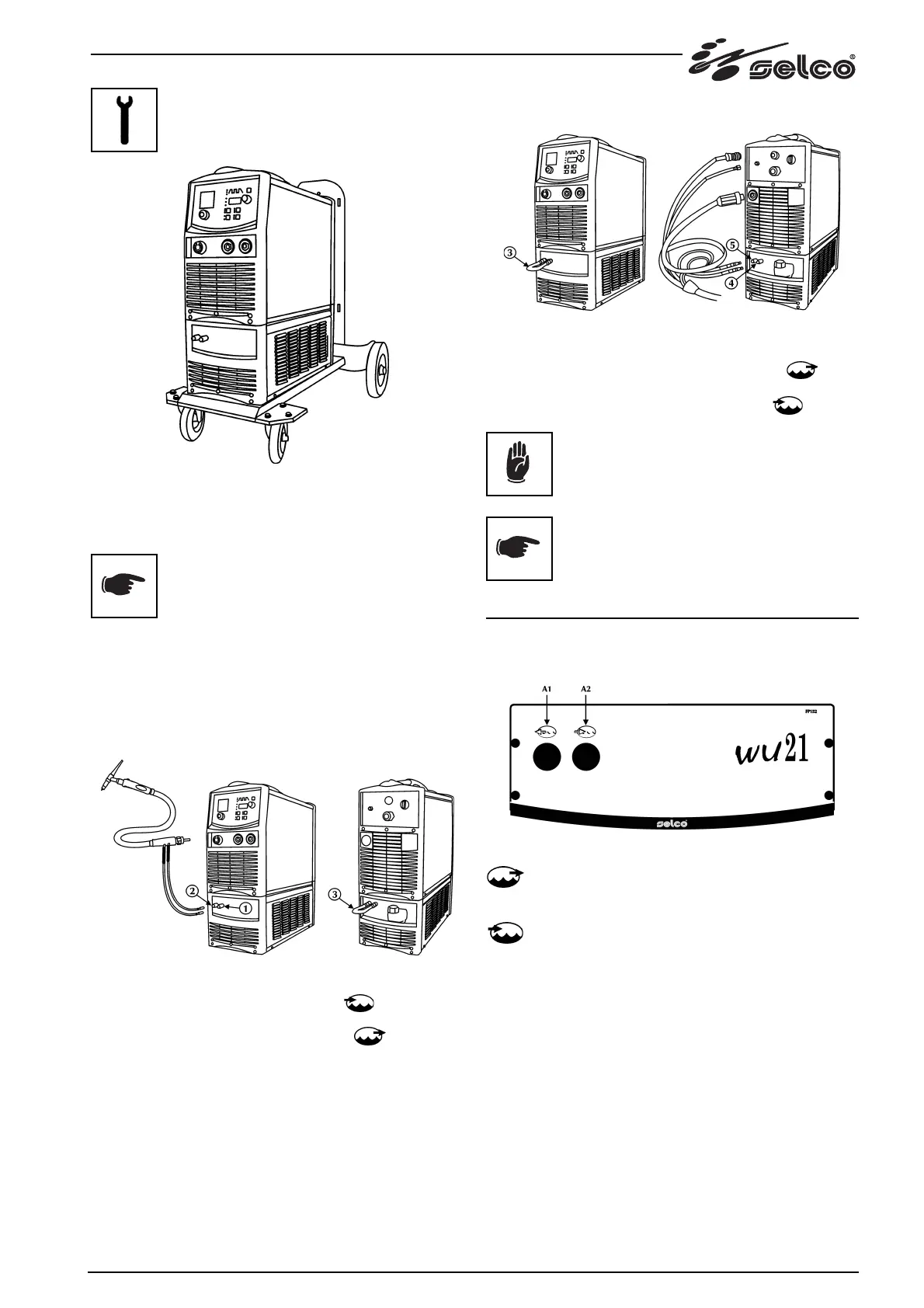

3 SYSTEM PRESENTATION

3.1 Front panel

A1: cooling liquid outlet connector.

To supply low temperature liquid into the torch cooling

circuit.

A2: cooling liquid inlet connector.

To return the liquid that has been heated by the torch

into the cooling circuit inside the WU.

Loading...

Loading...