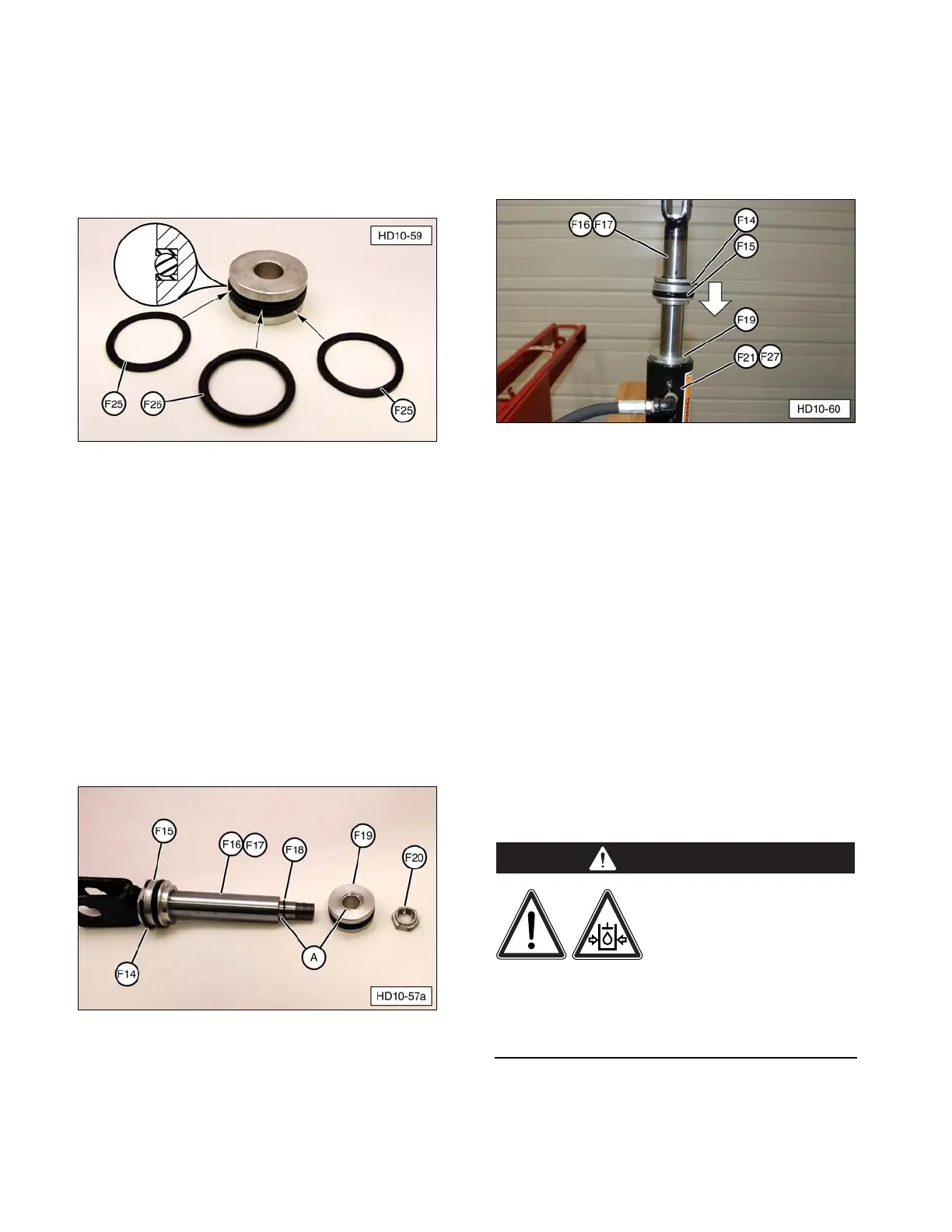

4. Install new scraper seal (F25) in the

cylinder piston groove, followed by O-ring

seal (F26), and the second scraper seal

(F25). Rounded (concave) surface of each

scraper seal (F25) must face (contact)

larger O-ring seal (F26).

(F25) Scraper Seal. (F26) O-ring Seal.

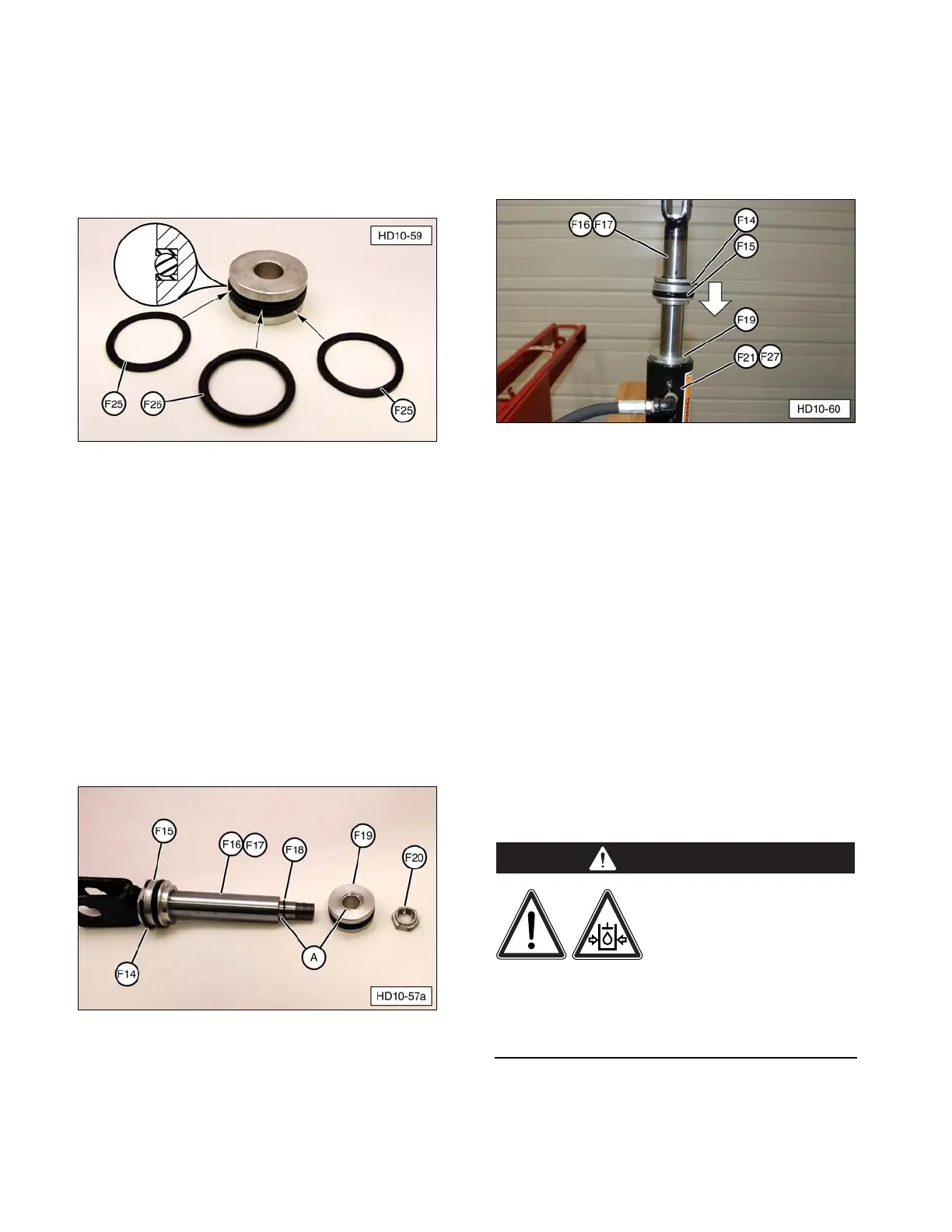

5. Install new O-ring seal (F18) on the

threaded end of cylinder rod (F16 or F17).

6. Lubricate the ID of cylinder cap (F15) with

clean hydraulic oil and install the cap onto

cylinder rod (F16 or F17) with the snap ring

groove facing up (toward the cylinder rod

mounting eye).

7. Lubricate the ID of cylinder piston (F19)

with clean hydraulic oil. Install the cylinder

piston on cylinder rod (F16 or F17) with the

O-ring relief (groove) (A) toward O-ring seal

(F18). Install new self locking nut (F20) and

tighten securely.

(F14) Snap Ring. (F15) Cylinder Cap.

(F16 or F17) Cylinder Rod. (F18) O-ring Seal.

(F19) Cylinder Piston (with seal). (F20) Self Locking Nut.

8. Lubricate cylinder tube (F21, F27) bore,

piston (F19) seals, and cylinder cap (F15)

seals. Install cylinder rod (F16, F17)

assembly into the cylinder tube, being

careful not to damage any seals.

(F14) Snap Ring. (F15) Cylinder Cap.

(F16 or F17) Cylinder Rod. (F19) Cylinder Piston

(with seal). (F21, F27) Cylinder Tube.

9. Push cylinder rod into cylinder tube until

snap ring (F14) in cylinder cap (F15)

contacts the top of the tube.

10. Use heavy-duty snap ring pliers to

completely compress snap ring (F14).

Push cylinder cap (F15) into cylinder tube

until the snap ring is completely seated in

the snap ring groove.

NOTE: It may be necessary to use a soft

(brass or wood) drift to tap the cylinder cap

and snap ring into place. Use caution not to

damage the aluminum cylinder cap.

Make sure the snap ring

is completely seated in

the cylinder tube groove.

Failure to seat the snap

ring in the groove can cause the cylinder cap

to be explosively ejected from the tilt

cylinder tube when hydraulic pressure is

applied, resulting in serious injury or even

death.

Loading...

Loading...