11. Install piston guide (C10) and new

self-locking piston guide nut (C11), using

a 1-1/4” wrench to hold the piston guide

while installing the piston guide nut. Do

not over-tighten the self-locking nut.

Piston guide (C10) must be able to rotate

on cylinder piston rod (C3).

12. Install cylinder piston rod (C3) assembly

into drive cylinder tube (C2).

NOTE: Care must be taken during installation

to prevent scoring of cylinder piston rod (C3) or

the inside of drive ram cylinder tube (C2).

13. Apply paste-type thread sealant (T12) on

drive cylinder tube (C2) external threads

and install cylinder cap assembly (C7).

Tighten cap securely.

IMPORTANT NOTICE

Hydraulic system fittings that require a thread

sealant must be installed with a paste-type

sealer only. Do not use a tape-type sealer, such

as Teflon Tape, as this can contaminate the

system and voids the valve warranty.

14. To install drive cylinder assembly (C1) in

the Post Driver, follow the instructions in

the Main Carriage Channel Assembly

section.

Main Carriage Channel Assembly

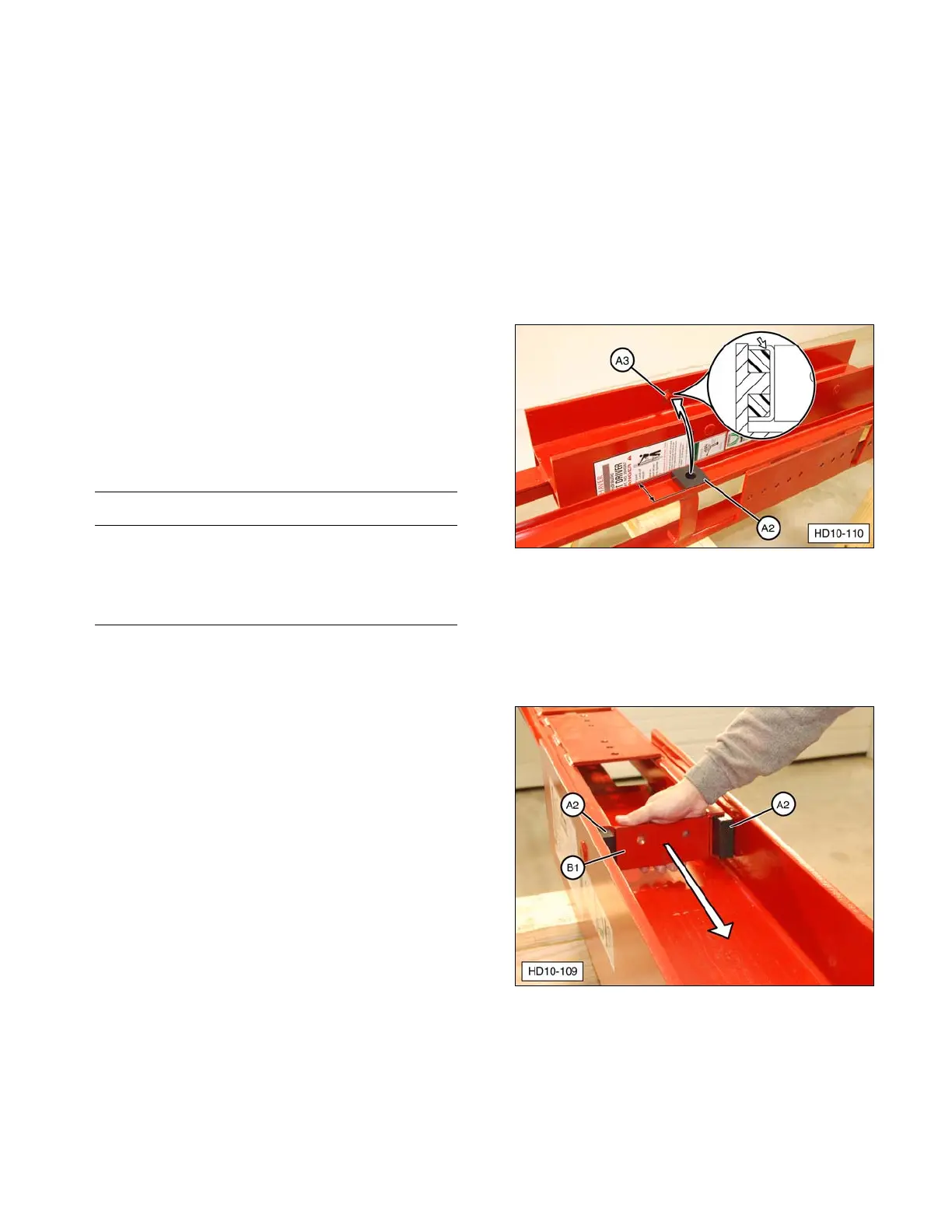

1. Install guide block shims (A3) and guide

blocks (A2) on the pins inside the drive ram

I-beam. Make sure the shims are installed

in their original locations.

NOTE: Chamfer (rounded edges) on guide

blocks must be positioned horizontally to

match the chamfer on the inside of the main

carriage channel frame.

(A2) Guide Blocks. (A3) Guide Block Shims.

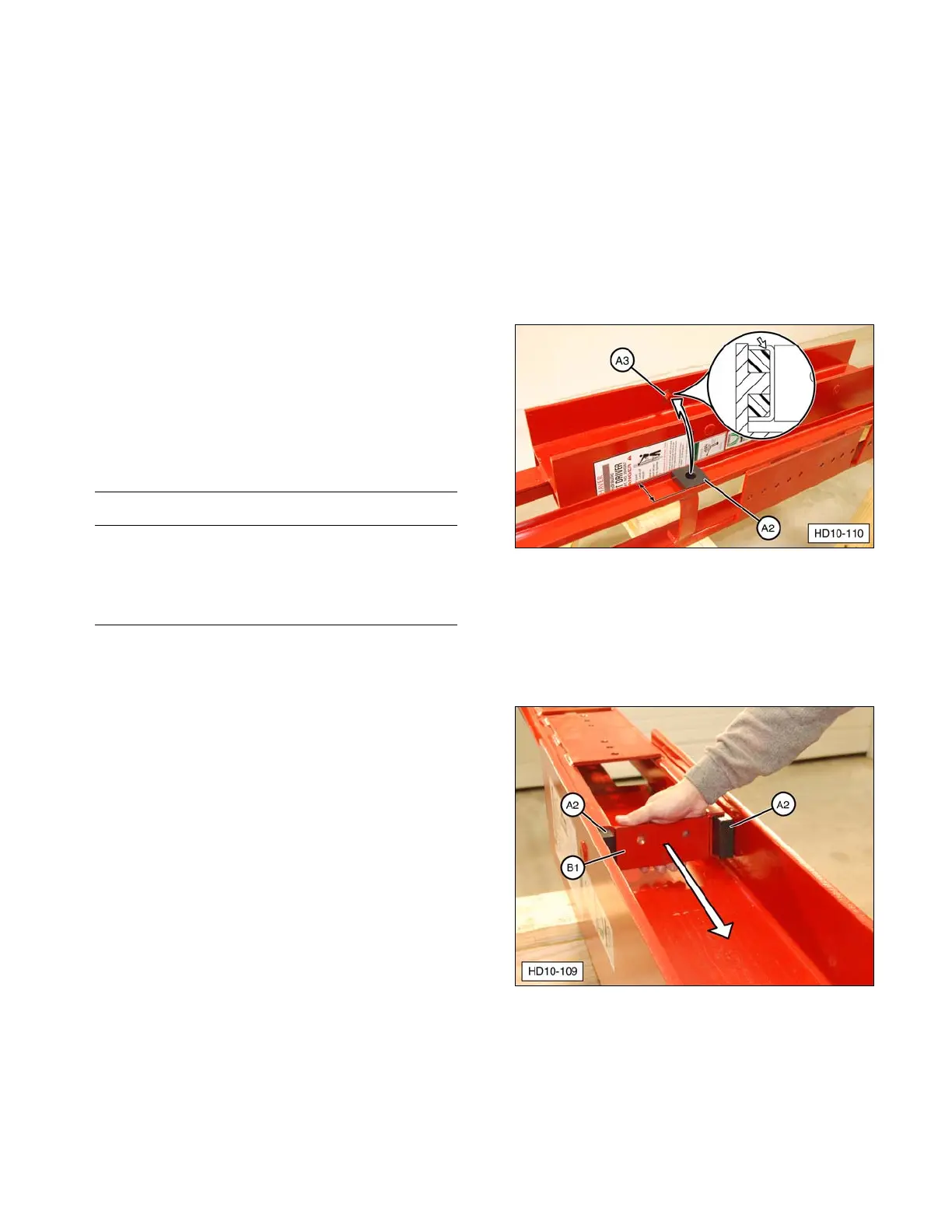

2. Lubricate the guide blocks with clean oil to

reduce friction. Get assistance to slide

main carriage channel (B1) over guide

blocks (A2) from the top of the drive ram.

(A2) Guide Blocks. (B1) Main Carriage Channel.

35

Loading...

Loading...