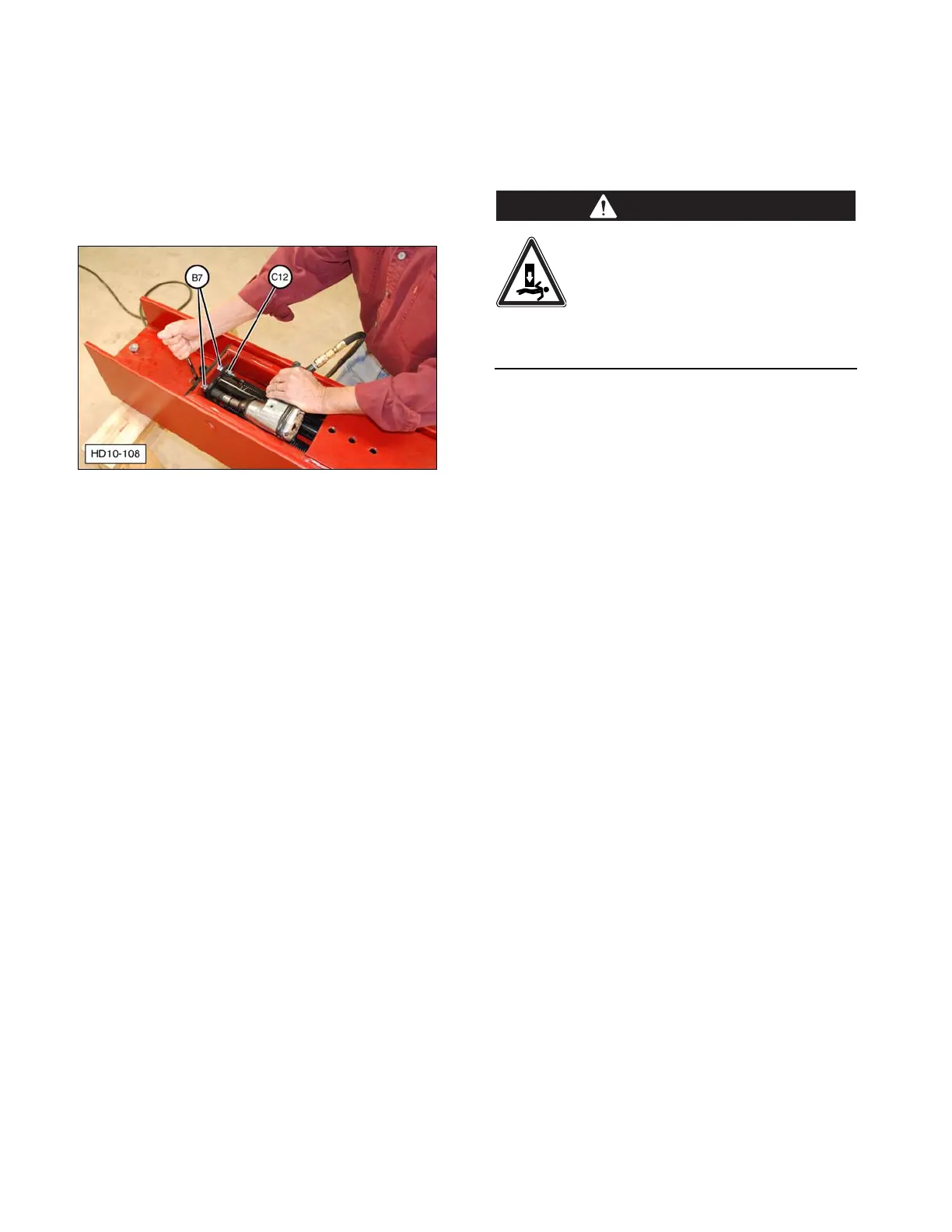

b. Completely tighten road lock bracket

nuts (B7) that were left loose in Step 7.

c. Completely tighten self-locking nuts

(C12) that were left loose in Step 8.

Tighten each nut slightly, in turn, to

align the drive cylinder inside the main

carriage channel.

(B7) Road Lock Bracket Nuts. (C12) Self-locking Nuts.

13. Pull main carriage channel (B1) down and

install road lock pin (B8) and Lynch pin

(B9) in lower hole in drive ram (A1).

14. To avoid binding, the drive cylinder and

rod must be parallel to the sides of the

main carriage channel. If necessary,

make the following adjustments:

a. Make sure the top drive ram cylinder

self-locking nut is loosened 1/2 turn.

b. Loosen lower drive ram cylinder

self-locking nuts (C12).

c. Tighten or loosen each nut slightly, in

turn, to align the drive cylinder inside

the main carriage channel.

NOTE: Self-locking nuts (C12) do not have to

be completely tightened against the lower

spring bracket.

Forward and Side Tilt Cylinder

Maintenance

Cylinder Disassembly

Removing tilt cylinder(s) from the

assembled Post Driver can cause an

unstable condition. To avoid

personal injury or death, make

sure the drive ram is stable and fully

supported by other means before removing

the tilt cylinders for service.

1. If removing cylinder(s) from the assembled

Post Driver, make sure the drive ram is fully

supported by other means, such as a

suitable overhead lifting device, before

disconnecting the tilt cylinders.

2. Disconnect the tilt cylinder hydraulic hoses

from the hydraulic control valve. Plug the

hoses and control valve fittings to prevent

dirt from entering the hydraulic system.

NOTE: Be prepared to collect any hydraulic

fluid that drains from the cylinder and hoses

into a suitable container.

3. Clean the outside of tilt cylinders (F3, F4).

Remove the tilt cylinders from the base

plate by removing the mounting pins.

4. Inspect the tilt cylinder mounting points.

Replace any worn or damaged

components.

Loading...

Loading...