Unpacking

Due to the size and weight of the

Post Driver, two people are required

for the assembly procedures.

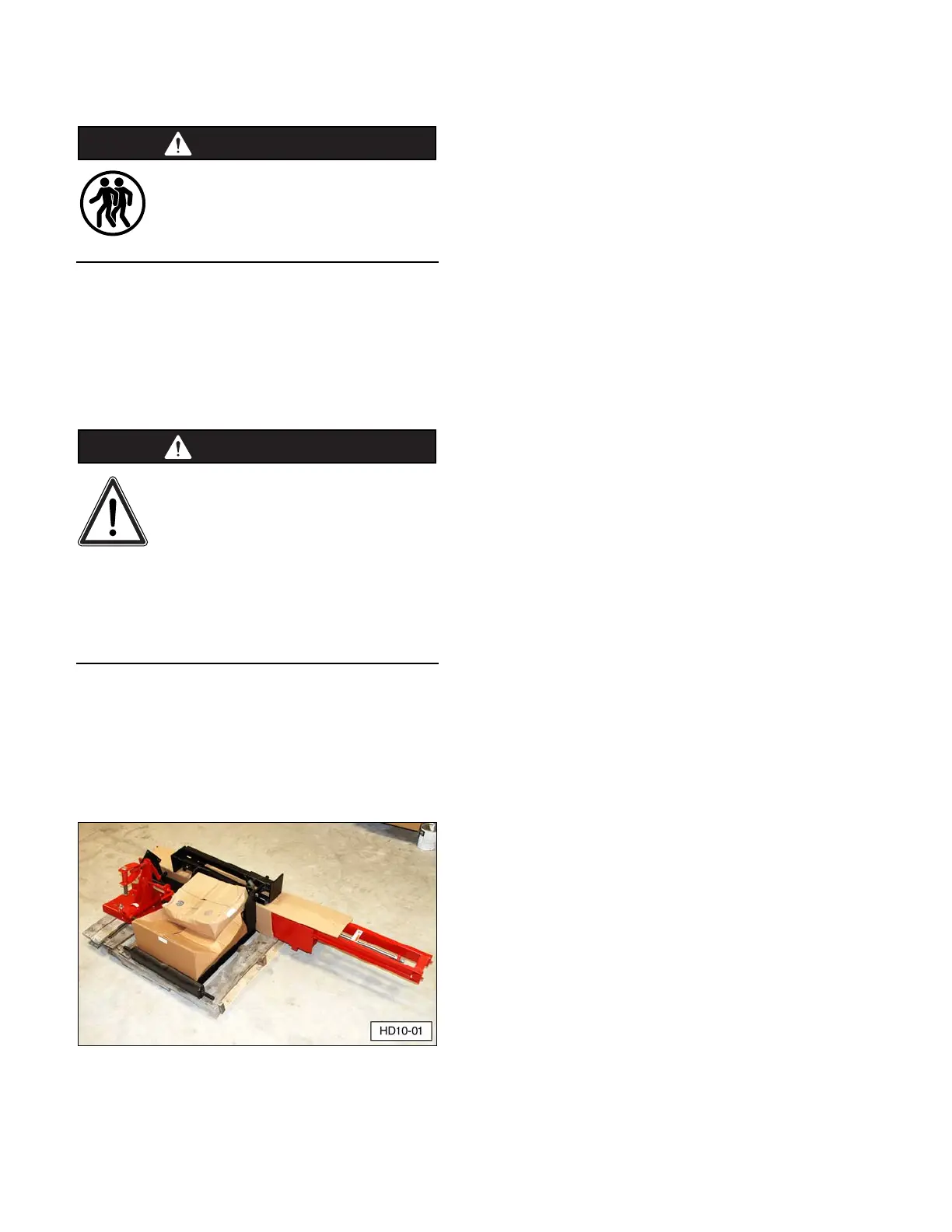

The Post Driver is shipped in several sections:

the driving ram assembly, base plate

assembly, short channel bracket, hose and

valve carton, safety arm carton, and on model

HD-10-H, the tilt cylinder carton.

Before starting the unpacking

procedure, make sure the

overhead lifting device or material

handling device (forklift) has

adequate lifting capacity. Follow all safety

recommendations when unpacking the Post

Driver. Some components are heavy and

can cause serious injury or death if not

adequately supported during removal and

assembly.

For ease of assembly, unload the Post Driver

components in the area where they will be

assembled. Choose a large, hard surface

area that can safely support the weight of the

assembled Post Driver and is accessible by

the machine it will be mounted on.

Assembly

NOTE: Refer to the Service Parts section of

this manual for a photo and description of all

the parts.

The HD-10 main carriage channel has

provisions for mounting the short carriage

channel bracket in three positions.

• Six middle bolt holes - three-point hitch

(most common position).

• Six upper bolt holes - tractor front mount.

• Six lower bolt holes - for driving

10 ft (3.0 m) tall posts only - three-point

hitch or front tractor mount.

The HD-10 and HD-10-H are shipped with the

carriage channel bolts installed in the middle

mounting position.

The Post Driver assembly procedure consists

of the following subsections:

1. Main Carriage Channel

2. Stabilizer Legs

3. Base Plate

4. Hydraulic Valve

5. Safety Stop Adjustment

6. Rubber Debris Guard

7. Safety Arm

8. Document Storage Tube

Loading...

Loading...