10(108)

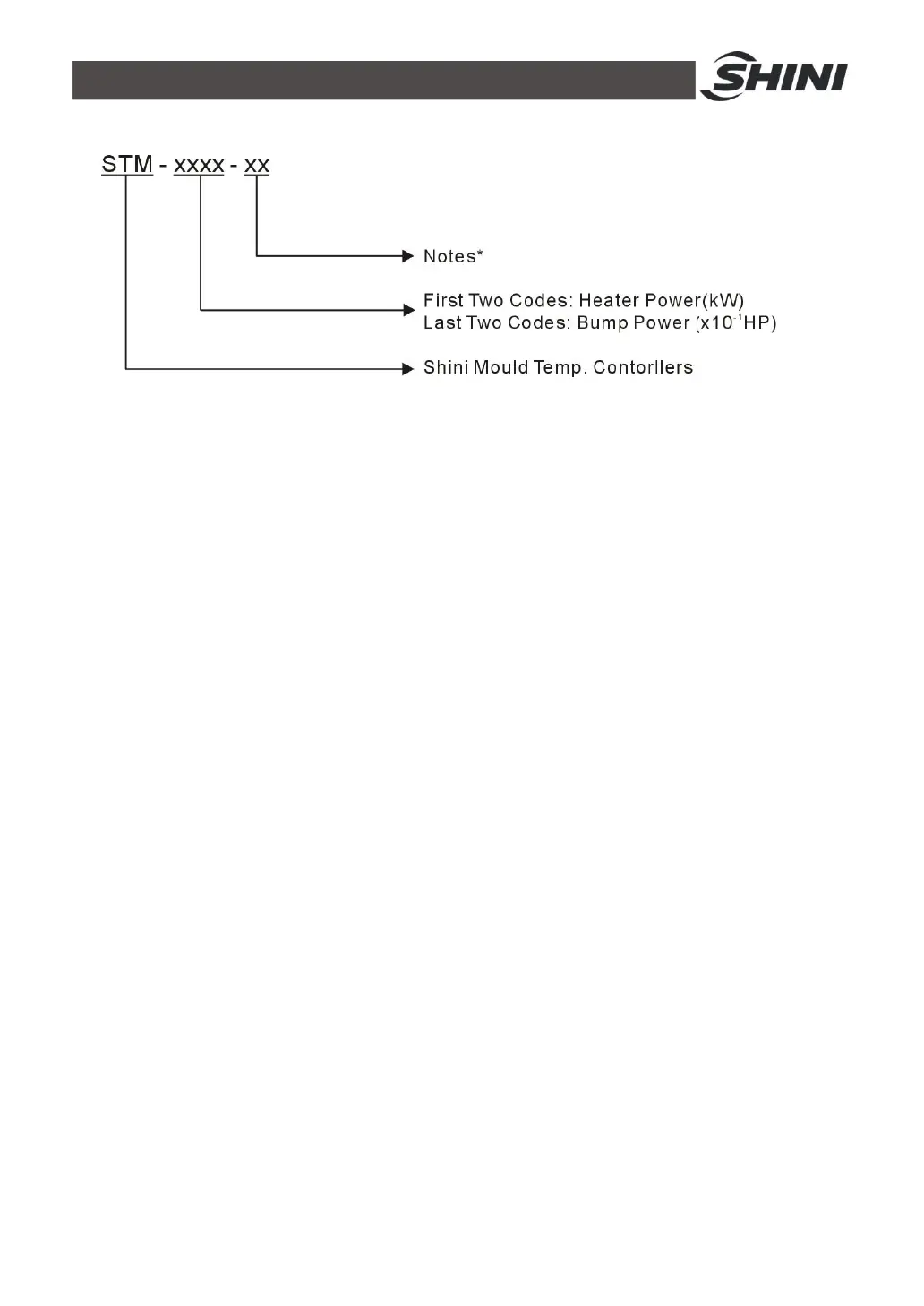

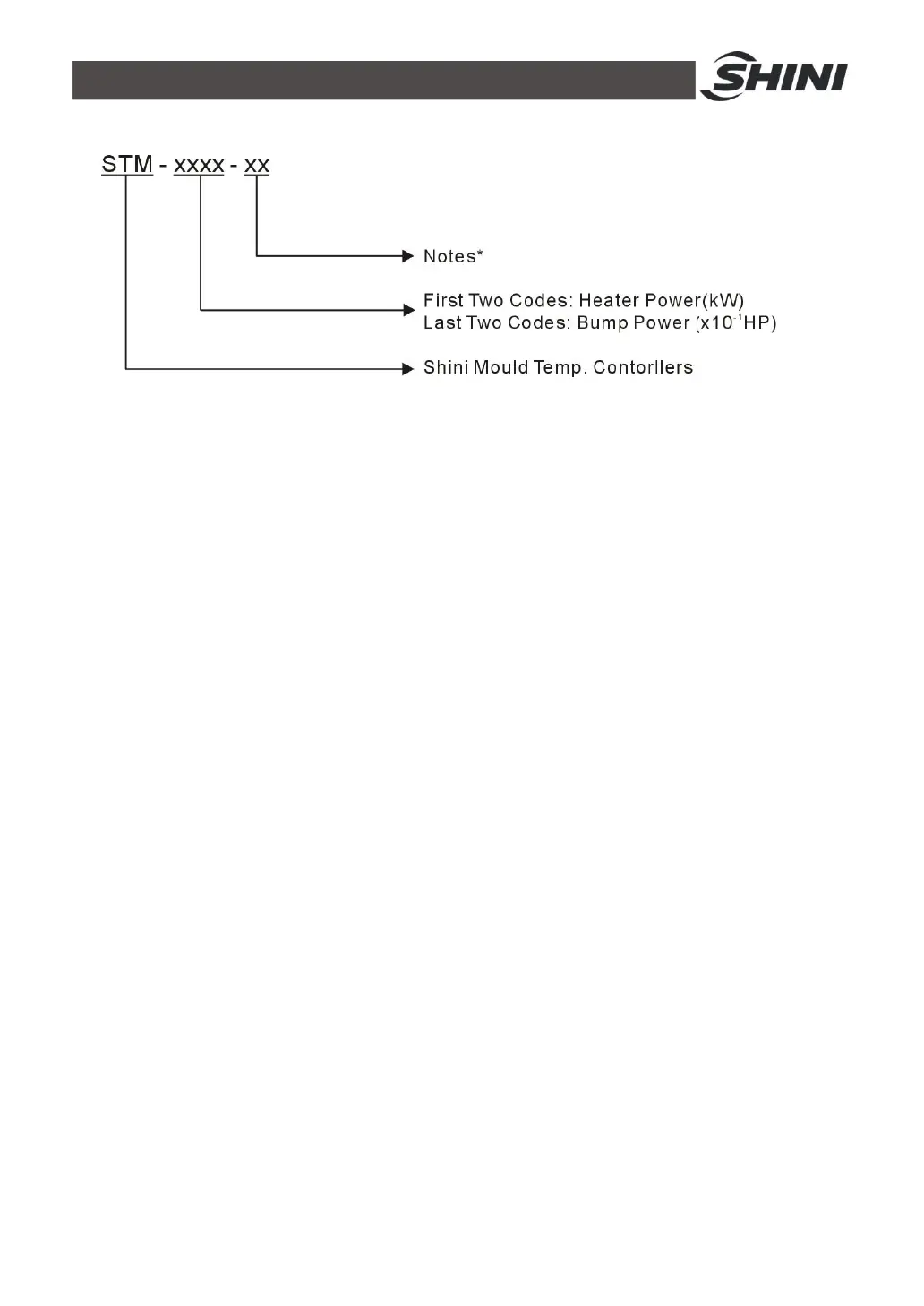

1.1 Coding Principle

Notes*

D=Dual-heating Zones HT=High Temperature Model

CE=CE Conformity M=Magnepic Pump B=Buzzer

1.2 Feature

1) Standard configuration

● Controller adopts 3.2" LCD for easy operation.

● Equipped with the design of 7-day automatic start/stop timer. LCD screen

can be converted between Chinese and English. The unit of temperature

can be converted between

o

F and ℃.

● P.I.D multi-stage temperature control system can maintain mould

temperature with accuracy of ±0.5℃.

● Adopts high efficiency high temperature pump, which can meet the demands

of temperature control for precise moulds and mould loop with minor

diameter to achieve precise temperature control and high efficient heat

exchange.

● Multiple safety devices including power reverse phase protection, pump

overload protection, overheat protection and low level protection that can

automatically detect abnormal performance and indicate this via visible

alarm.

● Pipe heater are made of stainless steel.

● For standard STM, the heating temperature can reach 200℃,while for

STM-HT, it can reach 300℃.

Loading...

Loading...