Technical Instructions LMV Series

Document No. LV5-800

0

Appendix A Page 12 SCC Inc.

Hot Standby with a Temperature Switch

Introduction

Hot standby is recomme

nded on multi-boiler systems to maintain one or more backup boilers

close to operating temperature. A simple hot standby with an LMV5 is accomplished through

the use of a temperature switch. A temperature switch closes a contact which allows the

burner to release to modulation and exit hot standby mode. With proper wiring and parameter

setup, this simple device will create an effective hot standby with an LMV5 controller.

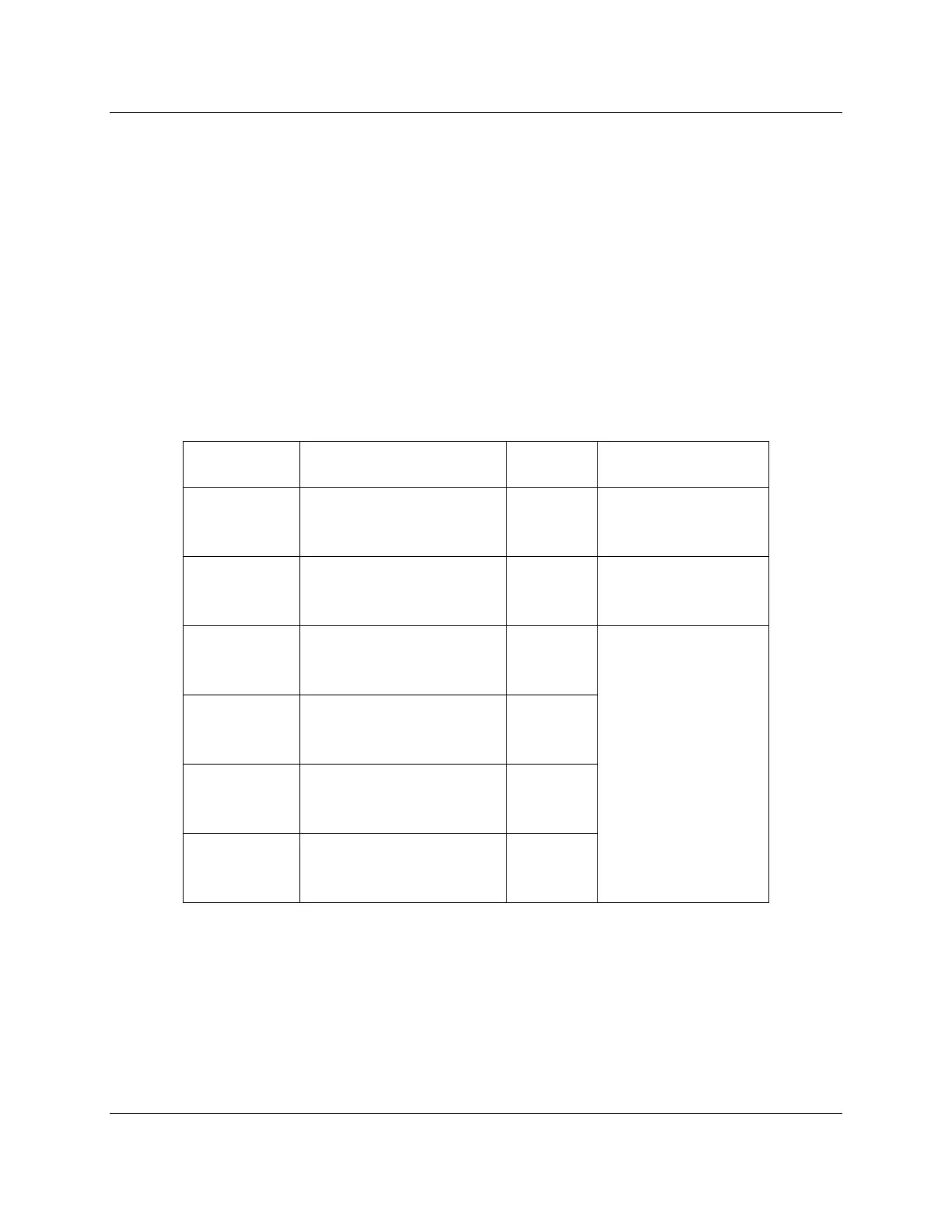

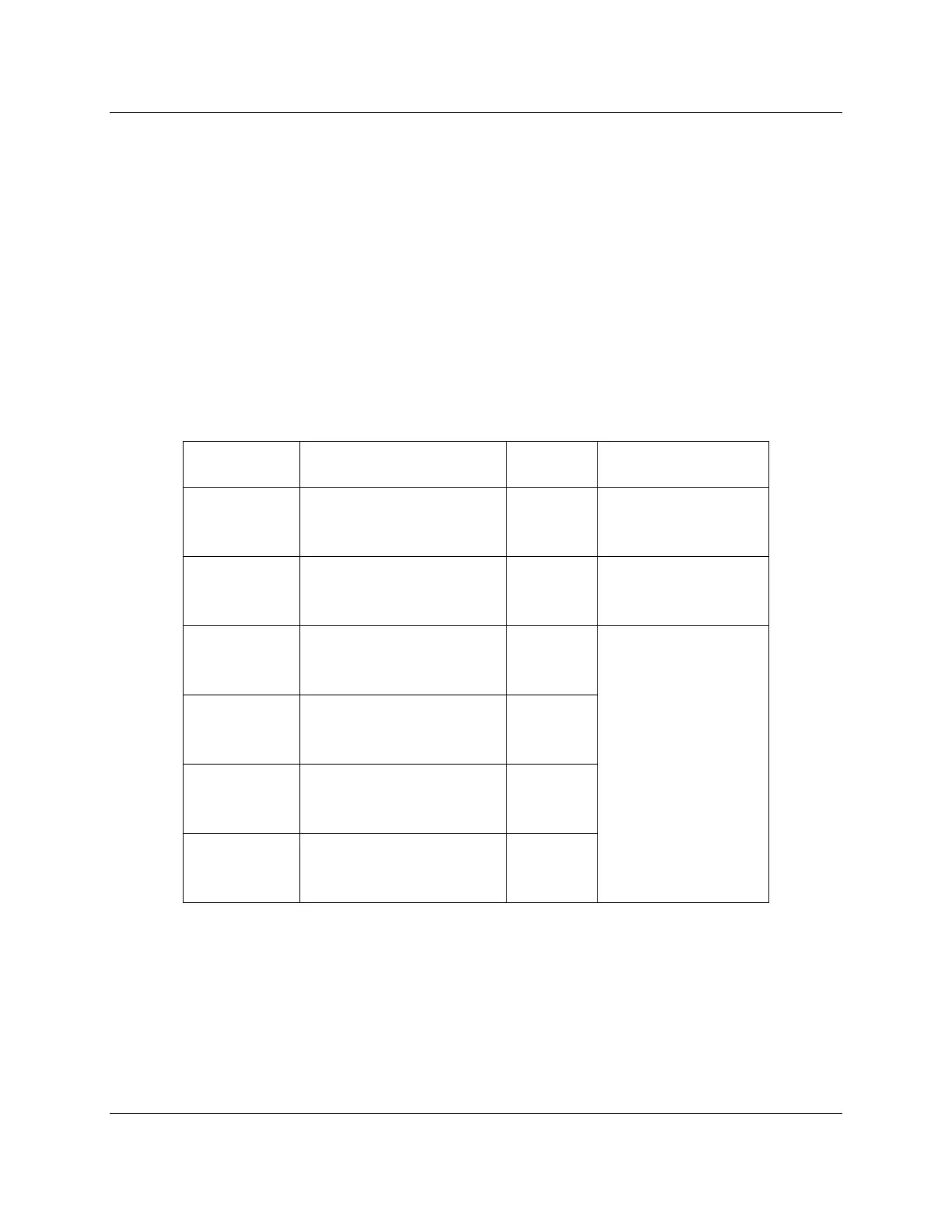

Table 3 describes the six different load controller operating modes in the LMV5.

Table 3: Description of LMV5 Load Controller Operating Modes

Label Description Setpoint

Upon X62.1 – X62.2

Contact Closure

ExtLC X5-03

External load control,

firing rate from

3-position input

N/A

Change to “IntLC”,

setpoint W1

IntLC

Internal load control,

setpoint set locally o

n

LMV5

W1

Remain in “IntLC”,

setpoint W2

IntLC Bus

Internal load control,

setpoint from

Modbus

command

W3

Change to “IntLC”,

setpoint W1

IntLC X62

Internal load control,

setpoint from a

nalog

signal on terminal X62

Remote

setpoint

ExtLC X62

External load control,

firing rate from a

nalog

signal on terminal X62

N/A

ExtLC Bus

External load control,

firing rate from

Modbus

command

N/A

If any operating mode other tha

n “IntLC” is used, a contact closure between terminals X62.1

and X62.2 will cause the LMV5 to revert back to operating mode “IntLC”. This concept is

necessary to achieve a hot standby with a temperature switch.

Loading...

Loading...