Result

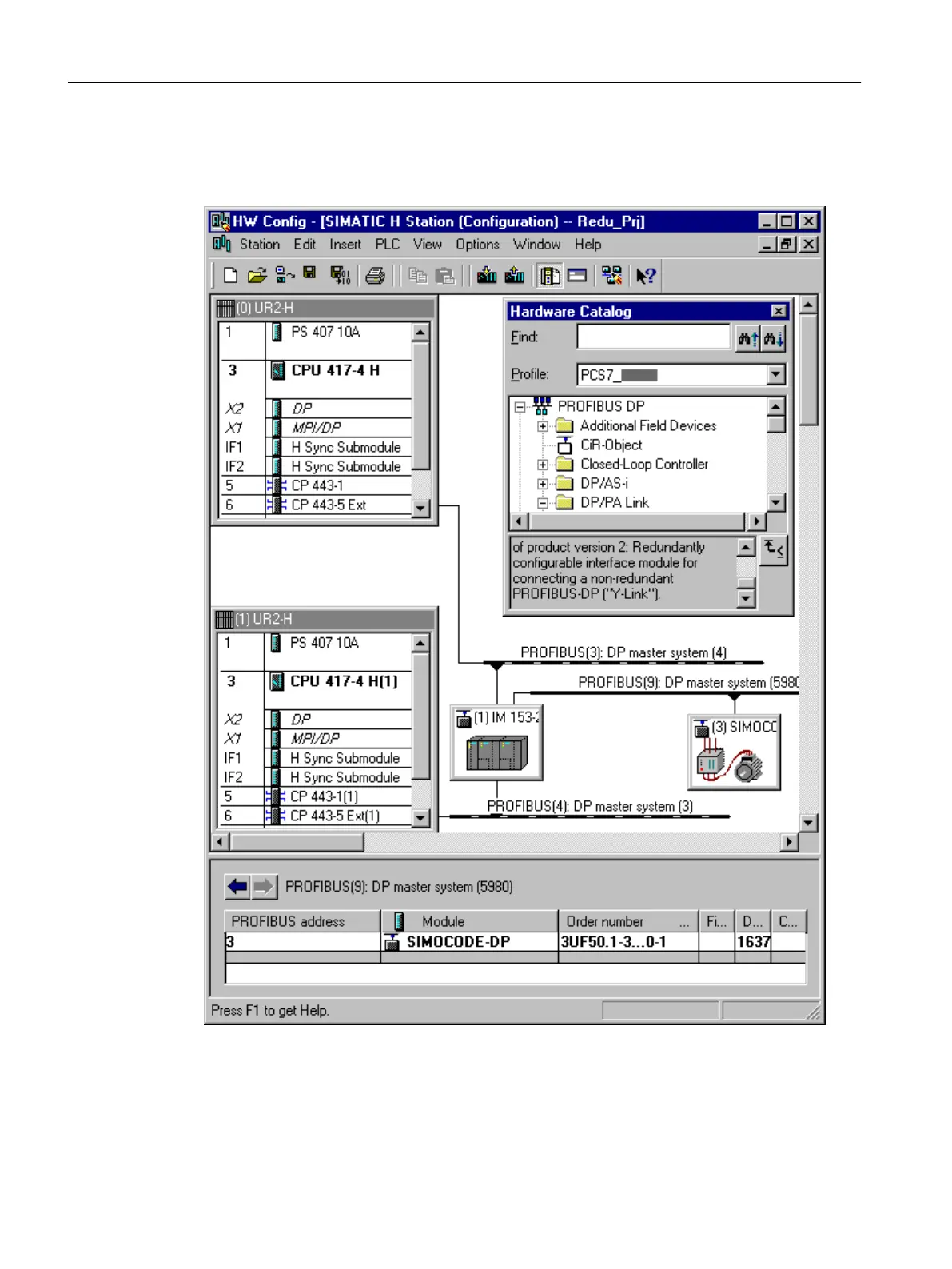

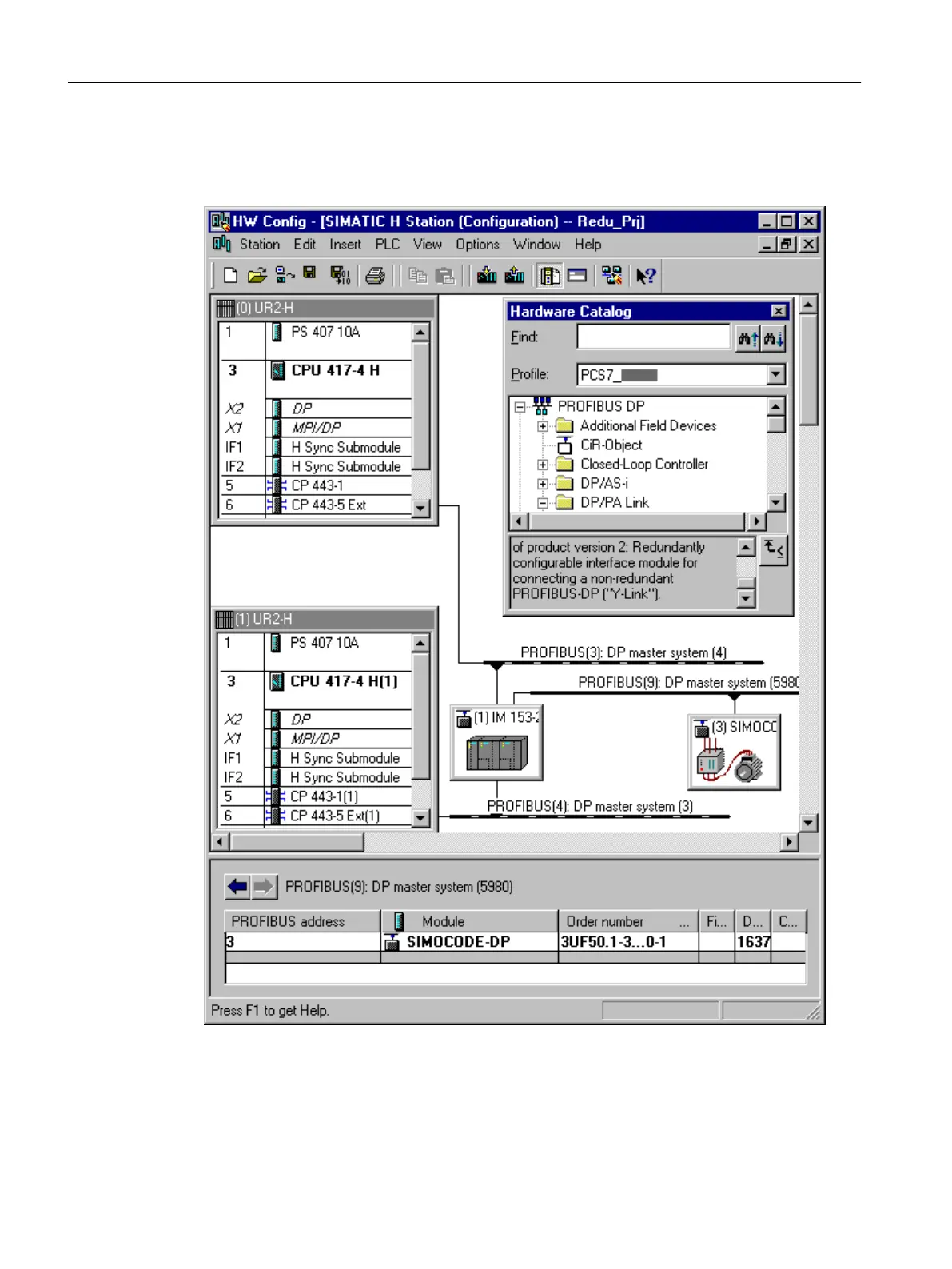

The following figure shows an example configuration in HW Config:

Additional information

● Manual

DP/ PA Link and Y Link Bus Couplings

Advantages of high availability components

5.4 Distributed I/O

High Availability Process Control Systems (V9.0)

146 Function Manual, 05/2017, A5E39221836-AA

Loading...

Loading...