3.4 Features of the PCS 7 redundancy concept at a glance

Introduction

The easiest way to increase availability is to keep replacement parts in stock on site and to

have fast service at your disposal to replace defective components.

In this documentation, we provide you with PCS 7 software and hardware solutions that go

well beyond fast service and replacement part warehousing. It focuses on "automated high

availability process control systems".

System-wide, scalable solutions in PCS 7 available

Plants are divided into the following layers in PCS 7:

● Field layer

● Process layer

● Management level

The components of PCS 7 enable you to implement high availability solutions at all automation

system levels in the form and to the degree you desire. In PCS 7, individual components (such

as signal modules), complex systems (such as operator control and monitoring systems) and

complete plants can be configured in such a way that one sub-component can automatically

take on the function of another sub-component if it fails.

You decide which components in the plant require increased availability.

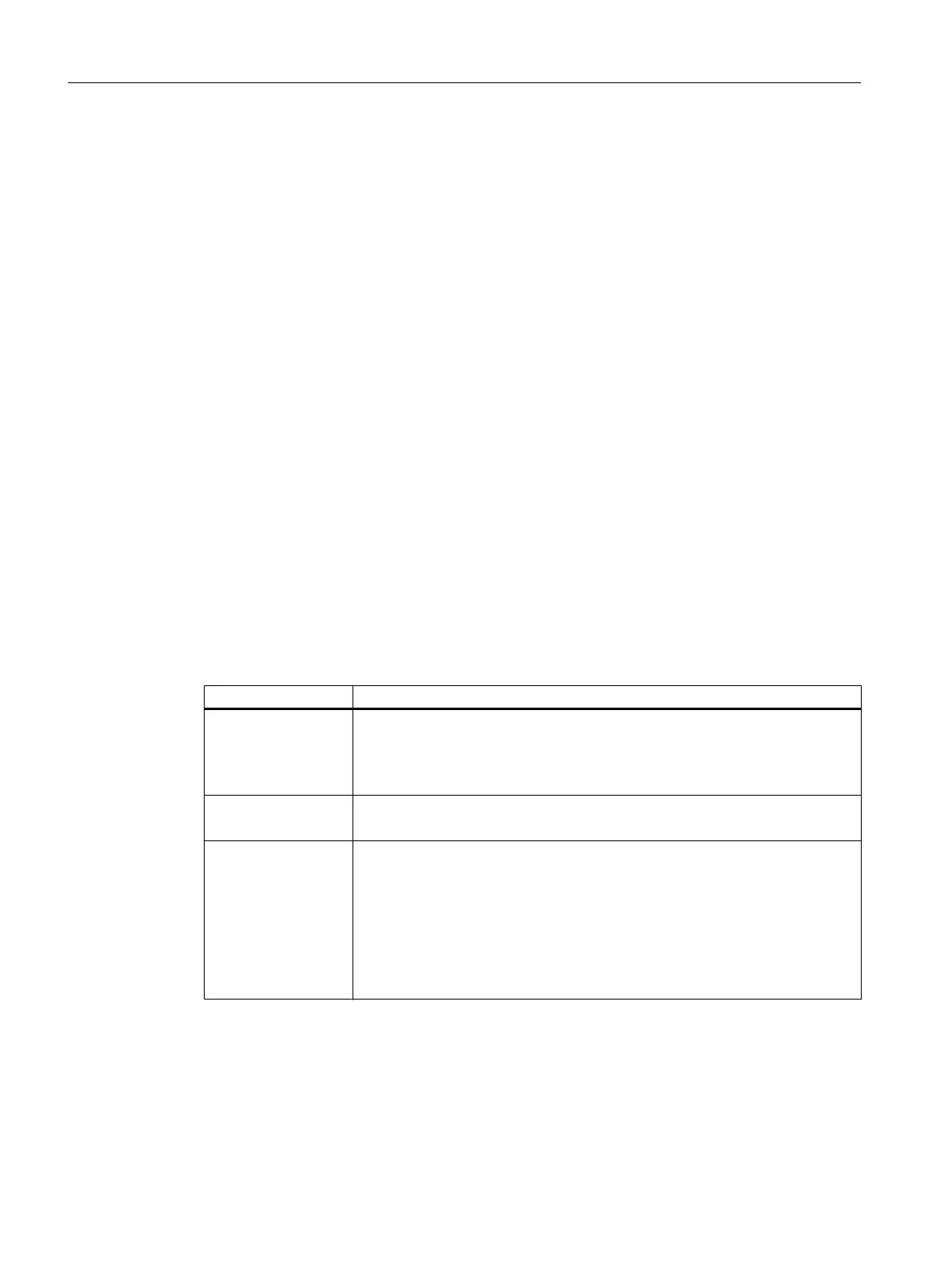

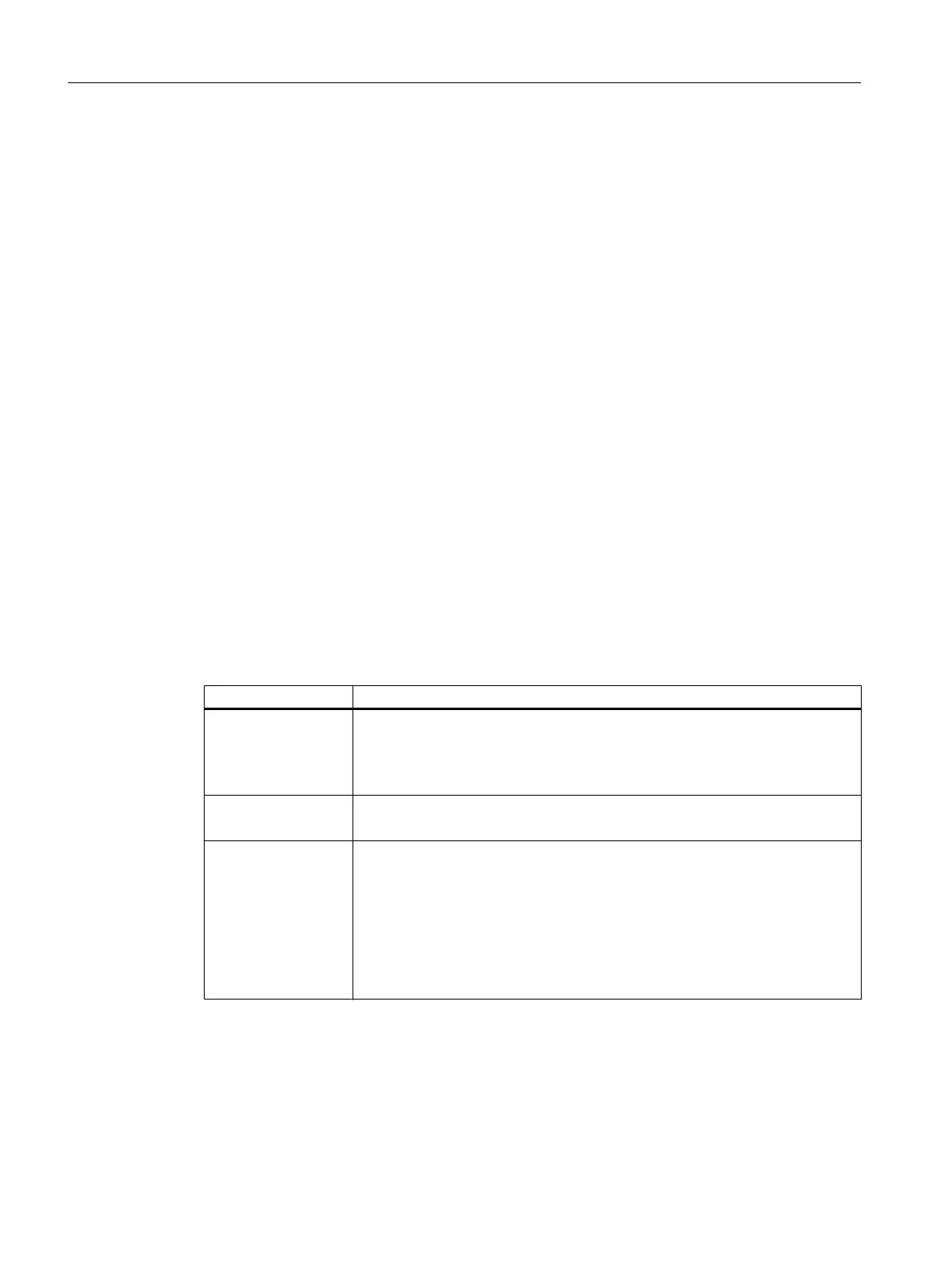

The following table lists the high availability components for the three layers.

Process layer Components

Management level OS clients, maintenance clients, BATCH clients, Route Control clients

OS servers, maintenance servers, Process Historian, information servers,

BATCH servers, Route Control servers

Terminal bus (Industrial Ethernet)

Process layer Plant bus (Industrial Ethernet)

Automation system AS 41xH

Field layer Fieldbus

● PROFIBUS DP, PROFIBUS PA, FOUNDATION Fieldbus, PROFINET IO

Distributed I/O device

● ET 200SP HA, ET 200M, ET 200SP, ET 200iSP, ET220S, and ET200pro

Field devices

● PROFIBUS DP, PROFIBUS PA, FOUNDATION Fieldbus and HART

devices

Basics of high availability

3.4 Features of the PCS 7 redundancy concept at a glance

High Availability Process Control Systems (V9.0)

24 Function Manual, 05/2017, A5E39221836-AA

Loading...

Loading...