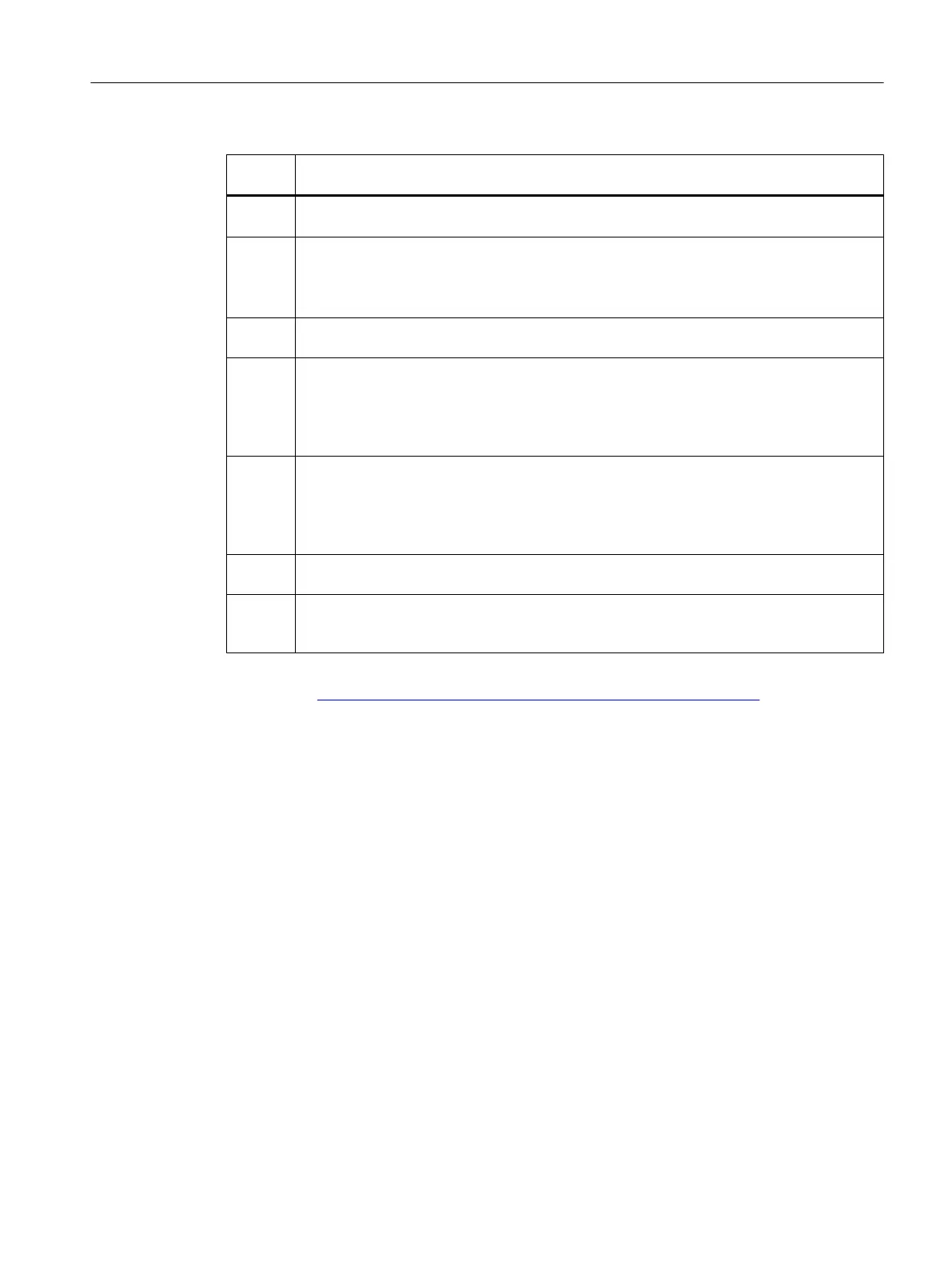

Number

*

Description

1 Several clients (OS clients, BATCH clients, Route Control clients) can access data on a

server (OS server, BATCH server, Route Control server).

2 Communication between the operator stations (client and server) and communication with

the engineering station is over a redundant, high availability terminal bus (Industrial Ether‐

net).

The clients and server are connected to the terminal bus via switches.

3 The servers (OS server, BATCH server, Route Control server, maintenance server, central

archive server) can, when necessary, be set up redundantly.

4 Automation systems communicate with the OS servers/Route Control servers and engi‐

neering stations and among themselves over the redundant, high availability plant bus (In‐

dustrial Ethernet).

The automation system, server and engineering station are connected to the plant bus via

switches.

5 Each part of the redundant, high availability S7-400H automation systems is connected to

the plant bus with an Ethernet communications processor (CP).

Each part of the AS is connected to several fieldbus chains (their PROFINET IO). The in‐

ternal fieldbus interfaces or additional communications processors are used for the attach‐

ment.

6 On PROFINET IO can be connected to the redundant distributed I/O devices based on

ET 200SP HA or ET 200M.

7 The ET 200SP HA IO Redundancy is the possibility to reduce the wiring effort with regard

to the connection of separate peripheral modules. The ET 200SP HA IO Redundancy is

optimized for usage with one sensor/actor per redundant channel pair.

For more information on usage of SIMATIC PCS 7 with PROFINET, refer SIMATIC PCS 7 with

PROFINET (https://support.industry.siemens.com/cs/ww/en/view/72887082).

Basics of high availability

3.3 PCS 7 redundancy concept

High Availability Process Control Systems (V9.0)

Function Manual, 05/2017, A5E39221836-AA 23

Loading...

Loading...