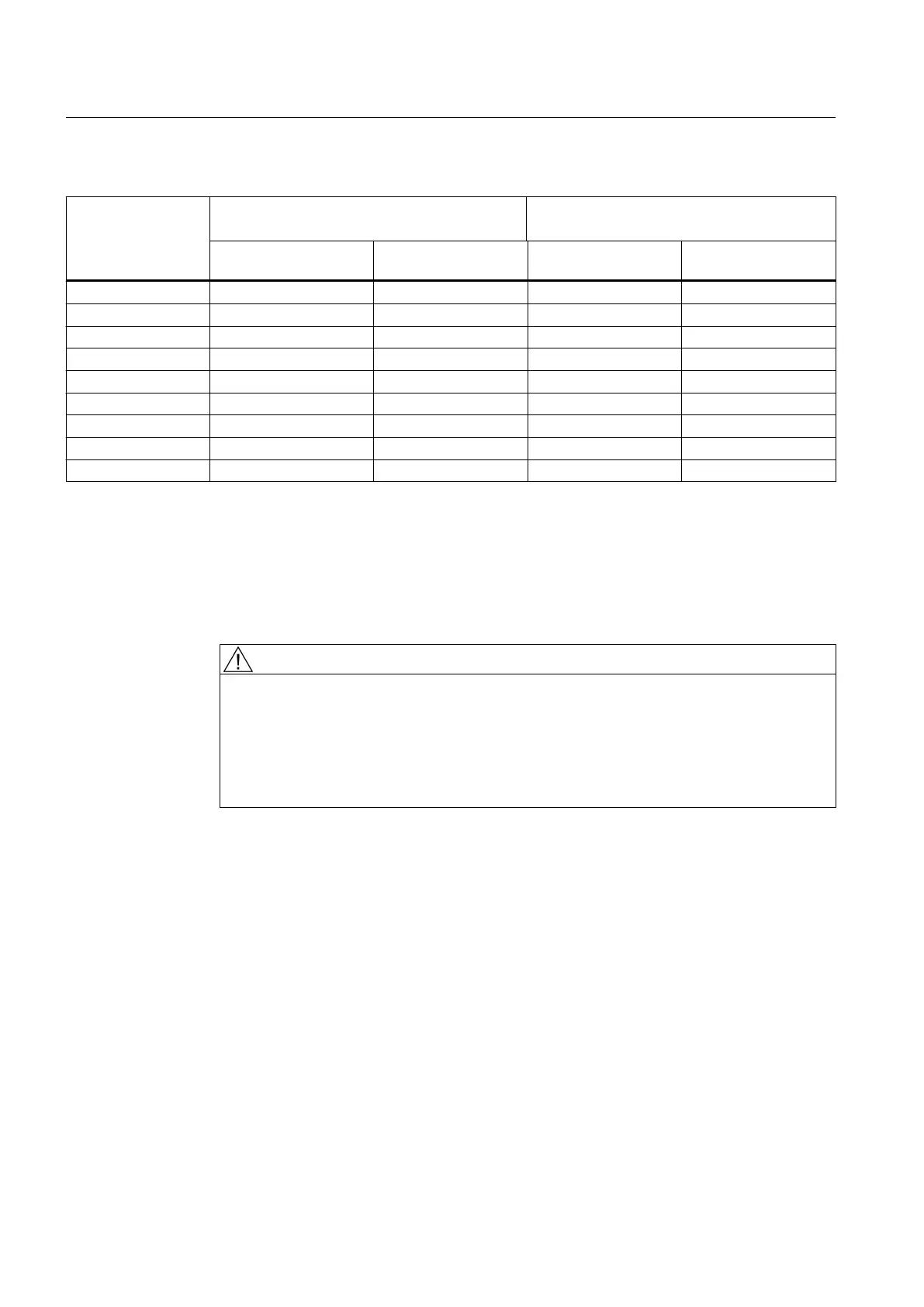

Table 6-2 Tightening torques for standard cable glands [Nm]

Nominal size Cable gland for Ex e II

Type HSK-M

Cable gland for Ex e / Ex d IIC

Type ADE 1F, ADE 4F R... / B...

Union nut Connection thread Union nut / connection

thread

Union nut / connection

thread

M12 x 1.5 5 7 7.5 -

M16 x 1.5 5 7 12.5 17

M20 x 1.5 5 7 20 23

M25 x 1.5 7 10 30 29

M32 x 1.5 7 10 55 33

M40 x 1.5 7 10 75 41

M50 x 1.5 7 10 100 50

M63 x 1.5 7 10 135 75

M75 x 1.5 - - 175 100

6.3.3 Cable ends with wire end sleeves

1. Preferably use end sleeves instead of soldering cable ends.

2. Before connecting, attach the end sleeves so as to form a technically correct, current-

carrying crimped joint at the end of the conductor.

WARNING

Risk of explosion due to excessive temperature rise

If the end of the conductor is not correctly enclosed by the end sleeve, but is trapped by

it, this can lead to overheating. The temperature class of the machine can be exceeded.

This can trigger ignition of an explosive mixture. This can result in death, serious injury or

material damage.

● Insert only one conductor end into each end sleeve. Attach the end sleeve correctly.

Electrical connection

6.3 Inserting and routing the cables

SIMOTICS HV C 1NB1402-2AA84-4CA0-Z

62 Operating Instructions 06/2018

Loading...

Loading...