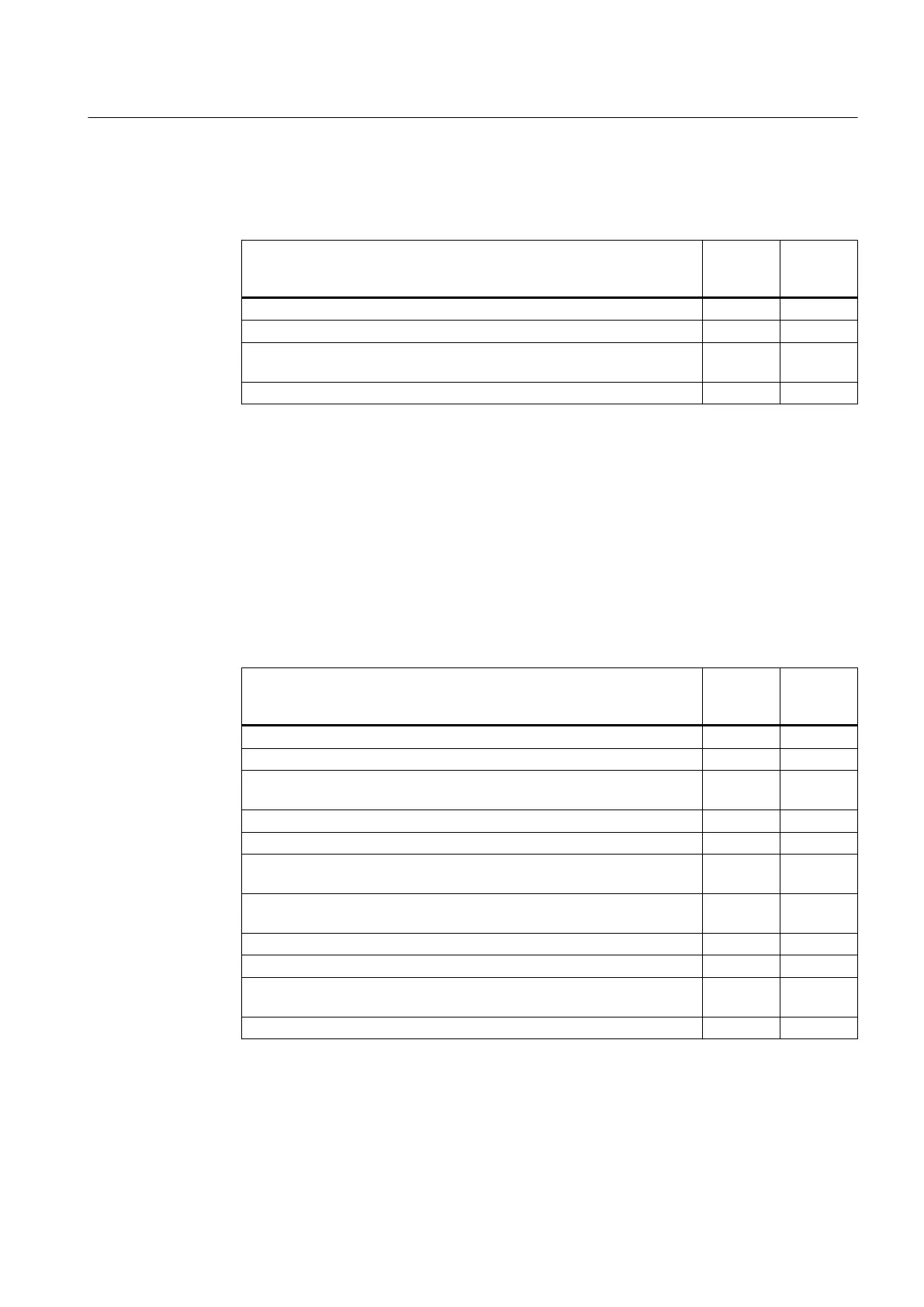

9.3.3 First service after installation or repair

● Check after approx. 500 operating hours, but after not more than one year:

Check When the

motor is

running

At stand‐

still

The electrical parameters are maintained. X

The permissible bearing temperatures are not exceeded. X

The smooth running characteristics and machine running noise have not

deteriorated.

X

The foundation has no cracks or indentations. (*) X X

(*) You can perform these checks while the motor is at standstill or, if required, while running.

● Further checks may be required if so specified in operating instructions of components

(Page 149) or in accordance with the plant-specific conditions.

● If you find any deviations during the inspection, you must rectify them immediately. They

may otherwise damage the motor.

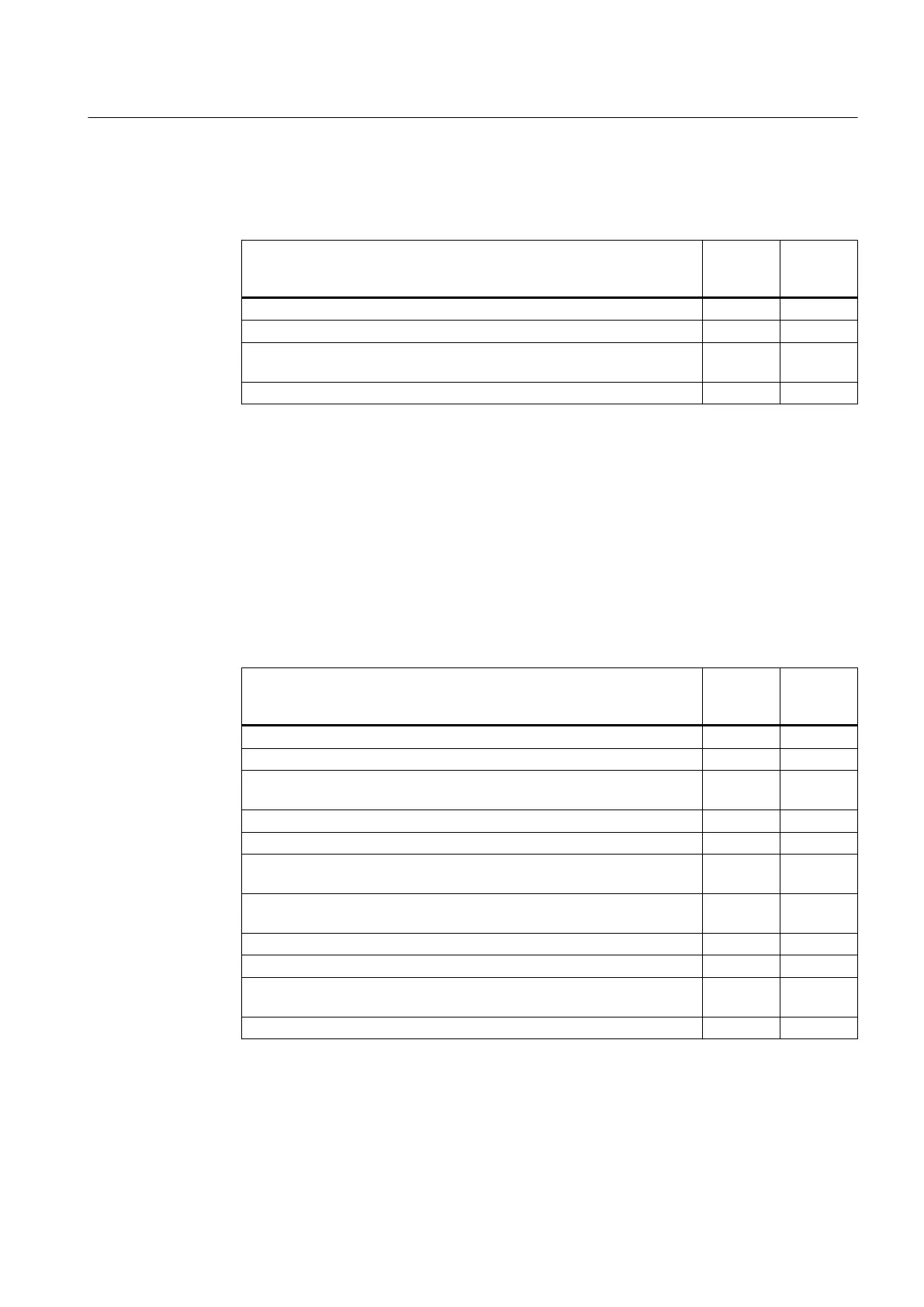

9.3.4 General inspection

● Check that the installation conditions are observed. Perform the following checks after

approx. 16 000 operating hours or at the latest after two years:

Checking When the

motor is

running

At stand‐

still

The electrical parameters are maintained X

The permissible bearing temperatures are not exceeded X

The smooth running characteristics and machine running noise have not

deteriorated

X

The foundation has no cracks or indentations. (*) X X

The machine is aligned within the permissible tolerance ranges. X

All the fixing bolts/screws for the mechanical and electrical connections

have been securely tightened

X

All the potential connections, grounding connections and shield supports

are correctly seated and properly bonded

X

The winding insulation resistances are sufficiently high (Page 40) X

Any bearing insulation is fitted as shown on the plates and labels X

The CABLES and insulating parts and components are in good condition

and there is no evidence of discoloring

X

Condensation can freely flow away. X

(*) This check can be made at standstill or when running.

● If you detect any deviations during the inspection, you must rectify them immediately. They

may otherwise cause damage to the machine.

Maintenance

9.3 Inspection and maintenance

SIMOTICS HV C 1NB1402-2AA84-4CA0-Z

Operating Instructions 06/2018 89

Loading...

Loading...