● Machines with an oil-injection interference fit and a center hole ≥ M56 have an adapter

installed between the shaft and the shipping brace.

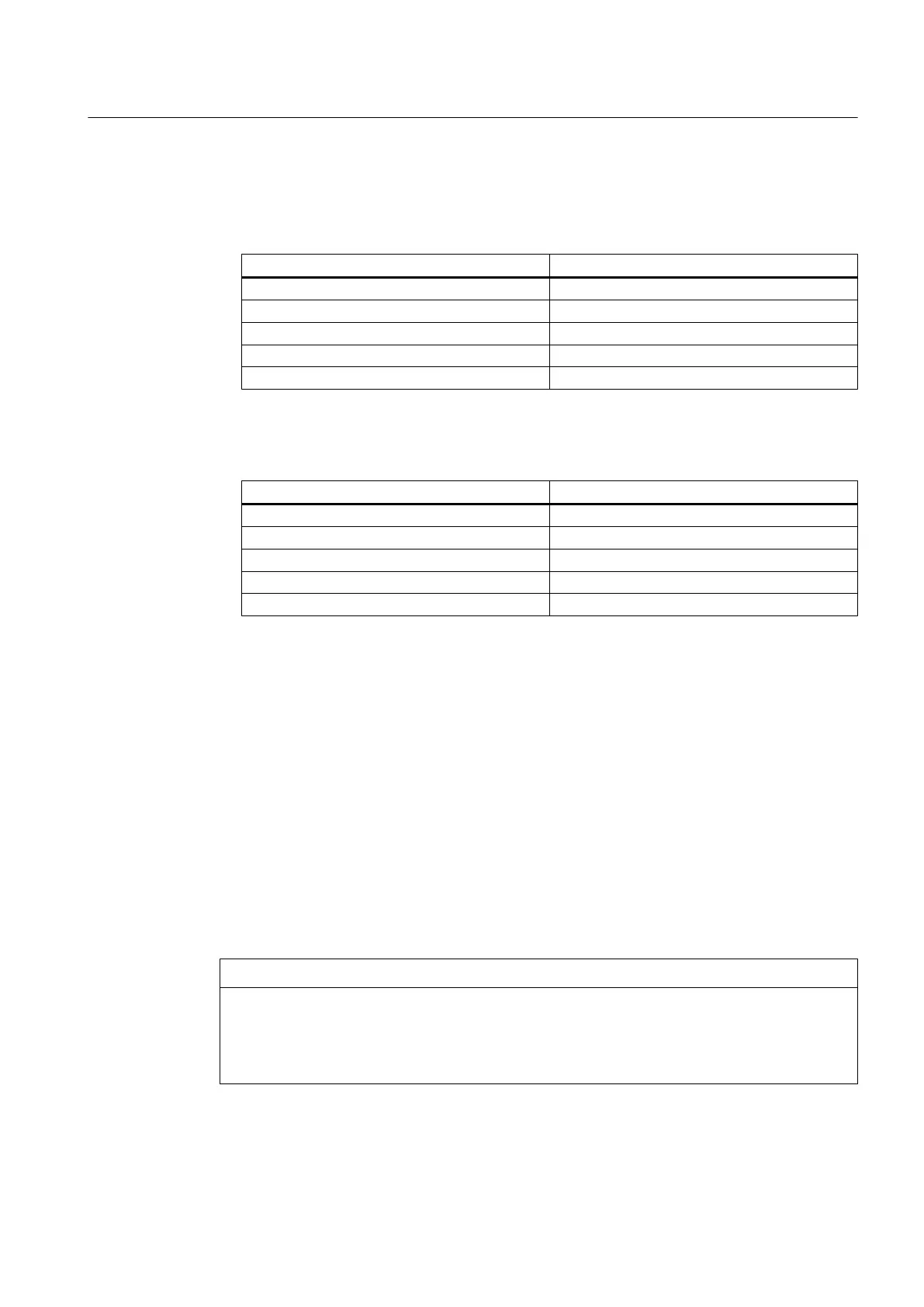

● Tighten the shaft screw ② on the rotor shipping brace to the following torques.

Thread in the shaft extension Tightening torque

M20 80 Nm

M24 150 Nm

M30 230 Nm

M36 350 Nm

M42 450 Nm

Tightening torques for other rotor shipping brace types

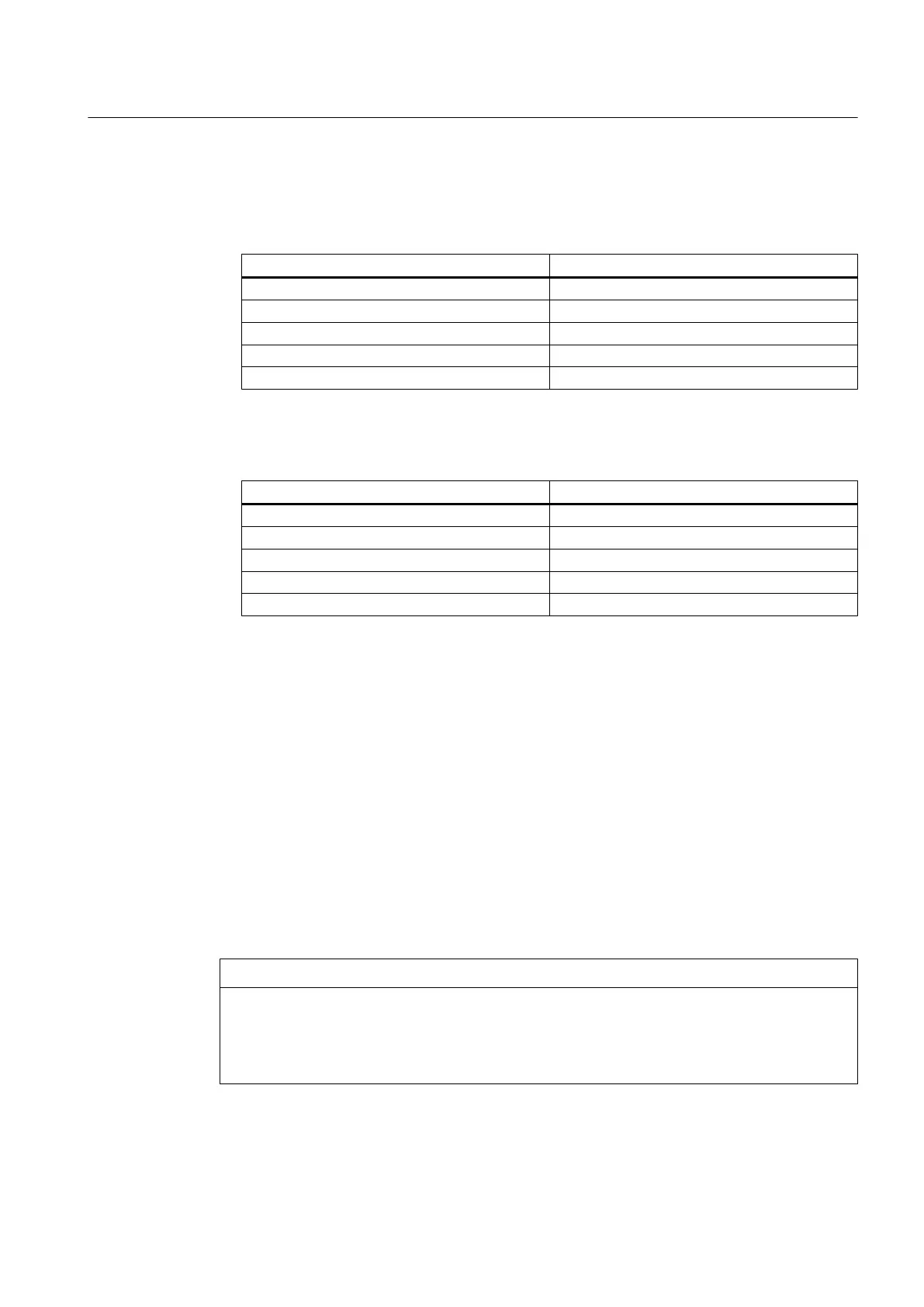

● The thread in the shaft extension indicates the rotor weight. This indirectly specifies the

required preload force when axially fixing the rotor.

Thread in the shaft extension Preload

M20 20 kN

M24 30 kN

M30 40 kN

M36 50 kN

M42 60 kN

Axial preload force for other rotor shipping brace types

4.13.7 Working on the underside of the machine

● Never remain under or in the immediate vicinity of the machine when it is lifted. If the lifting

gear or load handling attachments were to fail, the machine could fall. This can result in

death, serious injury or material damage.

● In order to gain easy and safe access to the underside of the machine, place it in a secure

and raised position.

4.13.8 Storage

You must correctly store the machine if you do not install and use it after it has been delivered.

NOTICE

Bearing seizure damage if incorrectly stored

If storage conditions are inappropriate there is a risk of bearing seizure damage. Resulting

damage can include scoring (brinelling) and corrosion.

● Follow the storage guidelines.

Preparations for use

4.13 Transport and storage

SIMOTICS HV C 1NB1402-2AA84-4CA0-Z

Operating Instructions 06/2018 33

Loading...

Loading...