General Engineering Information for SINAMICS

Engineering Information

SINAMICS Engineering Manual – November 2015

Ó Siemens AG

266/528

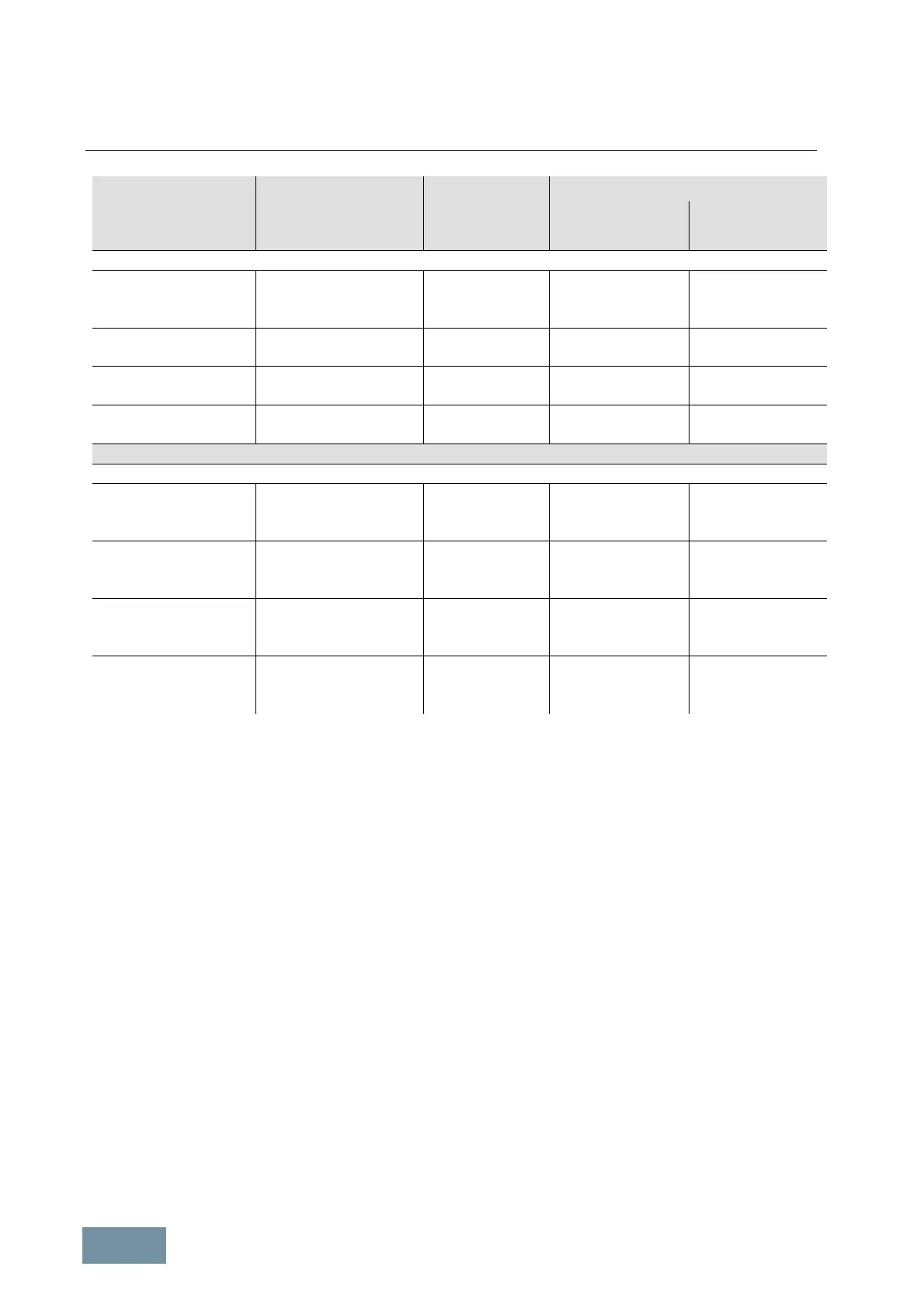

Air-cooled SINAMICS

drive component

Rated power Cooling air

requirement

[m³/s]

Minimum opening cross-section in cabinet

Inlet opening

(bottom)

[m²]

Outlet opening

(top)

[m²]

Motor Modules

§ Frame size FX 110kW at 400V;

132kW at 400V;

75-132kW at 690V

0.17

0.23

0.17

0.1

0.1

0.1

0.1

0.1

0.1

§ Frame size GX 160-250kW at 400V;

160-315kW at 690V

0.36 0.19 0.19

§ Frame size HX 315-450kW at 400V;

400-560kW at 690V

0.78 0.28 0.28

§ Frame size JX 560-800kW at 400V;

710-1200kW at 690V

1.08 0.38 0.38

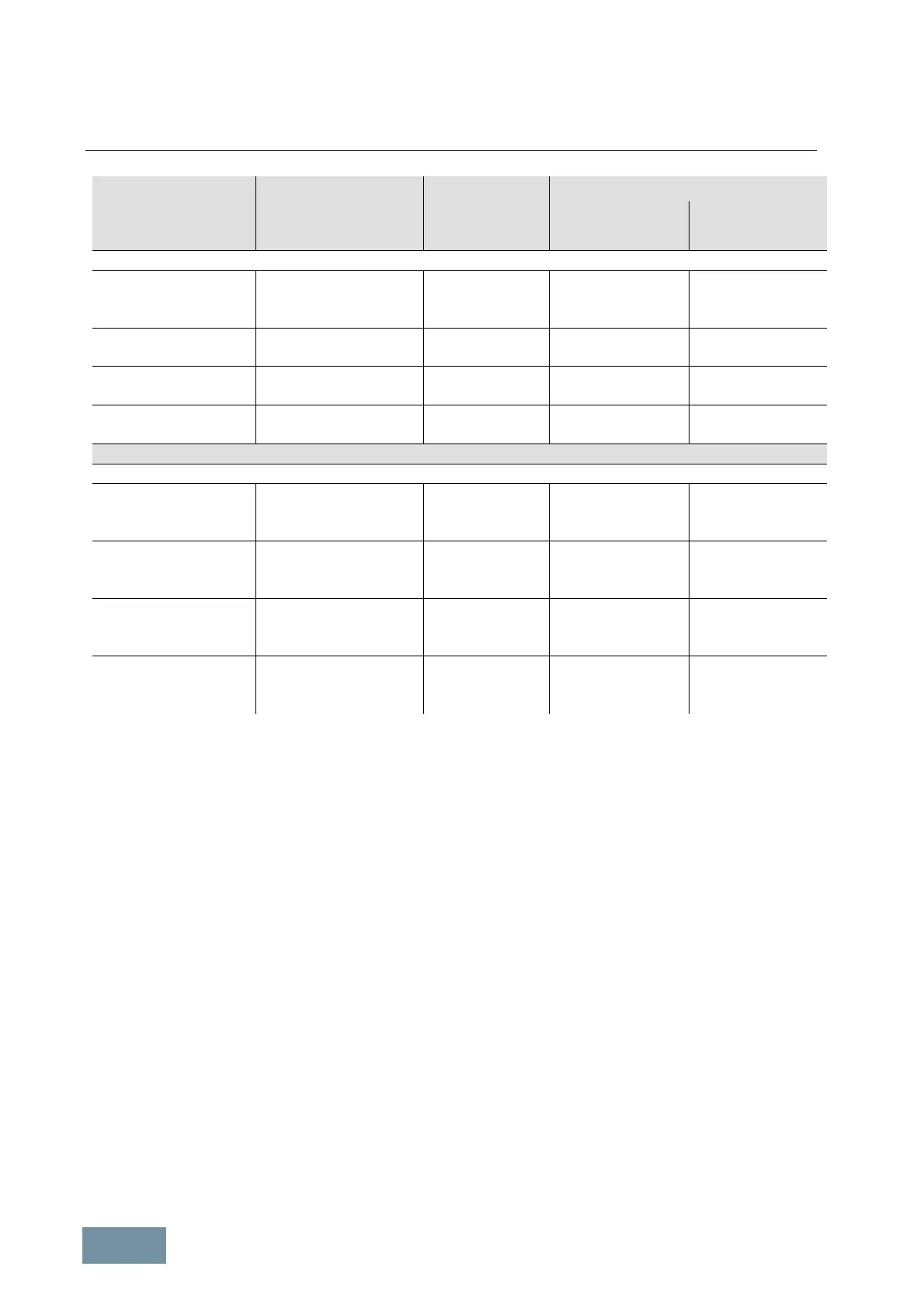

SINAMICS G130

Power Modules

§ Frame size FX 110kW at 400V;

132kW at 400V;

75-132kW at 690V

0.17

0.23

0.17

0.1

0.1

0.1

0.1

0.1

0.1

§ Frame size GX 160-250kW at 400V;

110-200kW at 500V;

160-315kW at 690V

0.36 0.19 0.19

§ Frame size HX 315-450kW at 400V;

250-400kW at 500V;

400-560kW at 690V

0.78 0.28 0.28

§ Frame size JX 560kW at 400V;

500-560kW at 500V;

710-800kW at 690V

1.48 0.47 0.47

Cooling air requirements and cabinet opening cross-sections for SINAMICS S120 Chassis and SINAMICS G130

To ensure reliable operation of the equipment in the long-term, it is essential to prevent the ingress of excessively

large particles of dirt or dust. Degrees of protection adapted to the ambient conditions on site must be provided for

the cabinets in the form of of wire lattices or filter mats. Cabinets installed in an environment where fine dust particles

or oil vapors may pose a risk must be protected by fine filter mats.

For cabinets with degrees of protection up to IP43, the air flow rate of the fans integrated in the Chassis units is

generally sufficient to ensure that sufficient cooling air can be conveyed through the cabinet openings (including wire

lattices or filter mats). This applies on the boundary conditions that the total opening cross-sections specified in this

section are provided on the cabinets and that the information about air guidance and cabinet partitioning in the

sections below is taken into account.

For cabinets which require a degree of protection higher than IP43 which will be achieved through the use of fine filter

mats, the air flow rate of the integrated fans will not be sufficient. In this case, the output power rating of the units

must be reduced or the total opening cross-section in the cabinet must be increased. Another alternative is to use an

"active" hood, i.e. a hood in which additional fans are integrated in order to increase the flow rate of air through the

cabinet. When selecting an "active" hood, it is important to ensure that the air flow rate of the integrated fans is

sufficient to prevent air from becoming trapped inside the cabinet. Trapped air would reduce the cooling capacity and

risk overheating and finally shutdown of the drive. For this reason, the air flow rate of the additional fans in the hood

must at least equal the air flow rate of the Chassis-integrated fans. The necessary air flow rates or cooling air

requirements can be found in the table above.

If the filter mats installed to provide higher degrees of protection become very dirty and clogged, they will pose an

increased flow resistance and thus reduce the flow of cooling air. The integrated fans may become overloaded as a

result, inevitably causing overheating and thus shutdown of the drive. To avoid this problem, filter replacement

intervals appropriate for the degree of contamination on site must be scheduled and strictly observed. In

environments in which the air is continuously heavily polluted, the filter replacement intervals might become very

short. As a consequence cost and effort involved in maintaining can become excessive. In this case, liquid-cooled

drive solutions with hermetically sealed cabinets should be installed instead of air-cooled drive variants.

Loading...

Loading...