SINAMICS S120 Cabinet Modules

Engineering Information

SINAMICS Engineering Manual – November 2015

Ó Siemens AG

387/528

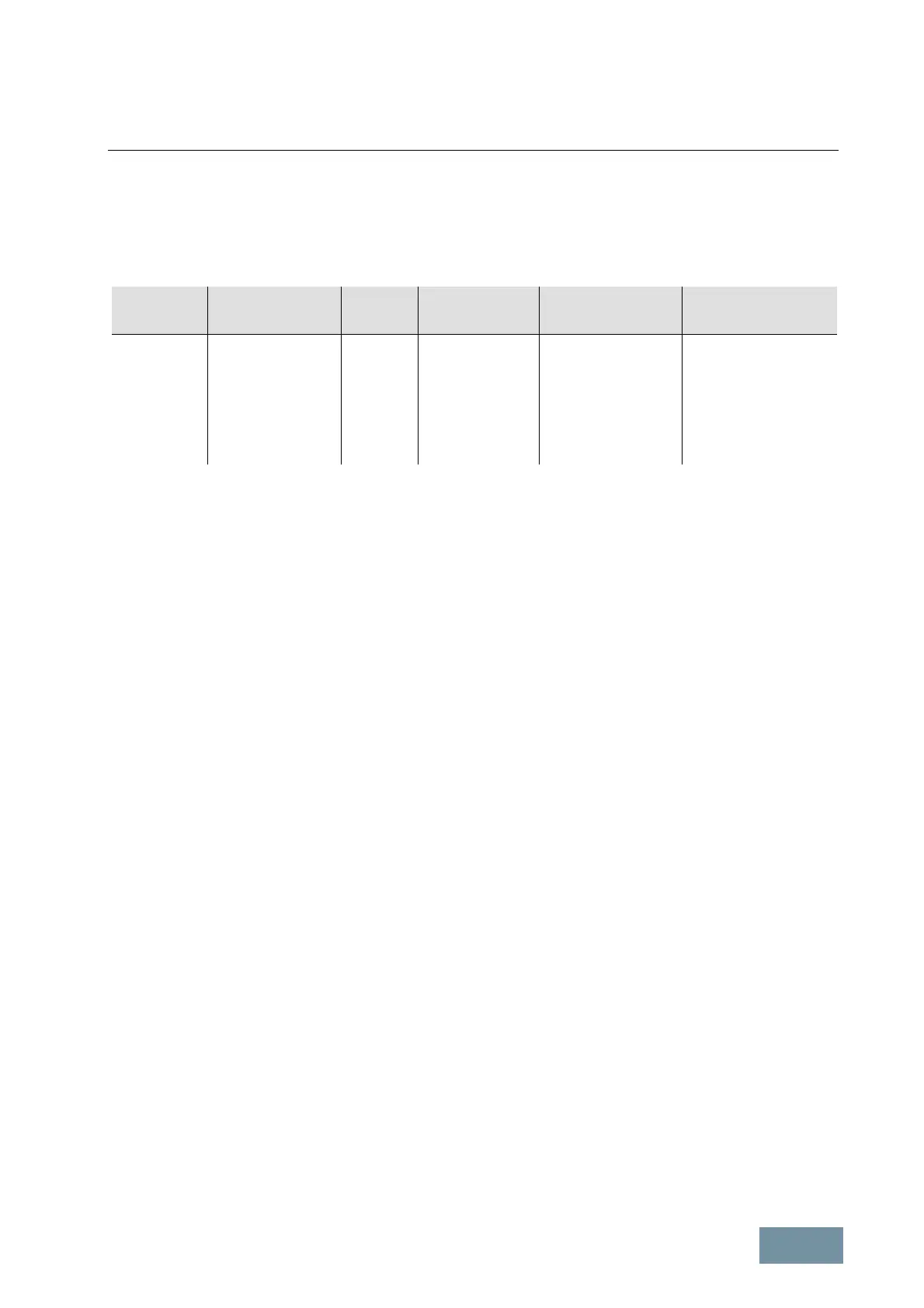

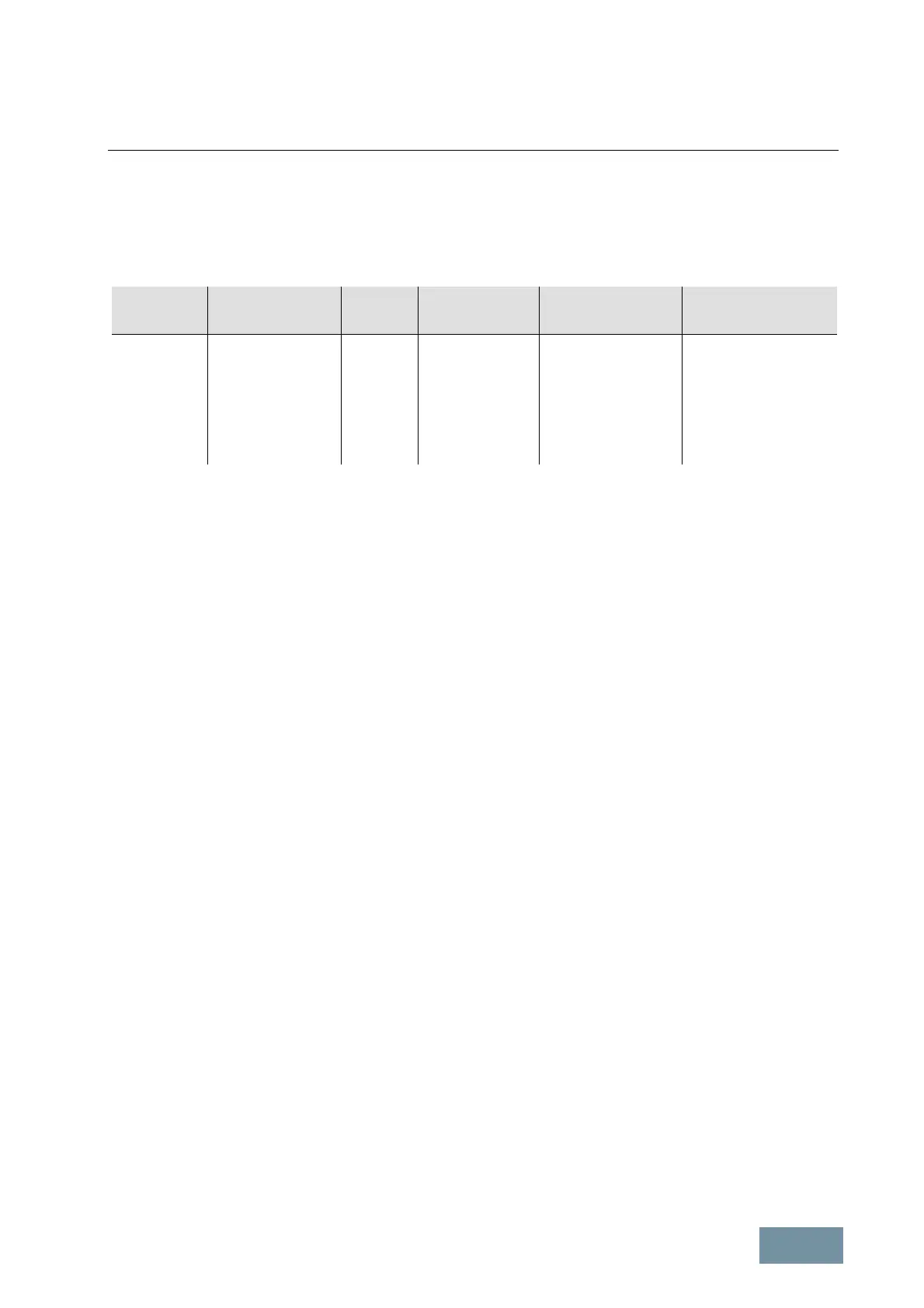

In order to determine the required DC busbar cross-sections, the potential DC link currents in normal operation must

be calculated as a function of the output of the individual Motor Modules and other general operating conditions

(simultaneity factors, overload factors, motor / generator operation). For optimum cost-effectiveness, different

combinations of DC busbar sizes can be selected. When selecting busbars, it is important to take in account that the

DC busbar systems of adjacent Cabinet Modules must be of compatible mechanical design (see table below and

option selection matrix for S120 Cabinet Modules in Catalog D 21.3).

Option

Order code

DC busbar

Rated current I

DC

[A]

Number

of parallel

bars

Bar

Dimensions

[ mm ]

Compatible with

option order code

Permissible

Peak short-circuit current

[ kA ]

M80 1170 1 60 x 10 M83 90

M81 1500 1 80 x 10 M84 and M86 85

M82 1840 1 100 x 10 M85 and M87 80

M83 2150 2 60 x 10 M80 180

M84 2730 2 80 x 10 M81 and M86 170

M85 3320 2 100 x 10 M82 and M87 160

M86 3720 3 80 x 10 M81 and M84 255

M87 4480 3 100 x 10 M82 and M85 240

DC busbar options

With some applications such as a gearing test stand, for example, one Motor Module is used to supply the

asynchronous motor which simulates a combustion engine, while other Motor Modules are driving asynchronous

motors that simulate the load. While the asynchronous motor simulating the combustion engine operates as a motor,

the load-simulating motors are feeding all their energy back into the DC link. As regards the total energy balance, this

means that only a small proportion of energy is drawn from the line supply (power losses of the complete drive

configuration plus energy required for acceleration). In this application, energy is mainly exchanged between Motor

Modules over the DC busbar. As regards the DC busbar design, this generally means that the busbar between the

Infeed (Line Module) and the first Motor Module can have a smaller cross-section than the busbars between the

Motor Modules when the modules are arranged in a line with the Infeed at the beginning of the line.

The Modules must be arranged according to the relevant load conditions and the simultaneity factor so that the DC

busbars can be selected as efficiently as possible with regards to the dimensions and costs.

After the DC busbars have been selected, it must be verified that all parts of the DC busbar system have sufficient

short-circuit strength. The permissible peak short-circuit currents are specified in the table above. The contribution of

the connected Line Modules (BLM, SLM, ALM) and Motor Modules (MoMo) to the total peak short-circuit current on

the DC busbar is specified in the tables in section "Short-circuit currents on the DC busbar" in chapter "Fundamental

Principles and System Description".

The DC busbars between the individual Cabinet Modules are interconnected by means of special busbar links. These

are part of the busbar system and are attached to the right-hand side of the bar for a module / transport unit when it is

delivered. When the Cabinet Modules have been lined up, the links can be unfastened, taken into the adjacent

cabinet and fastened tight again.

If option Y11 is selected for Cabinet Modules, i.e. if they are ordered as factory-assembled transport units, a uniform

cross-section of the DC busbar must be selected for each transport unit, as a continuous copper bar is installed

within each transport unit in this case.

7.2.2.4 Required cable cross-sections for line and motor connections

Generally speaking, unshielded cables can generally be used to make the line connection. 3-wire or 4-wire three-

phase cables should be used wherever possible. By contrast, it is always advisable to use shielded cables and, in the

case of drives in the higher output power range, symmetrical 3-wire, three-phase cables, between the converter and

motor and to connect several cables of this type in parallel where necessary. There are basically two reasons for this

recommendation:

- This is the only method of achieving the high IP55 degree of protection on the motor terminal box, as the

cables enter the terminal box via screwed glands and the number of glands is limited by the geometry of the

terminal box. Single cables are therefore less suitable.

- With 3-wire, three-phase cables, the the summed ampere-turns over the cable outer diameter are equal to

zero and they can be installed without any problems in conductive metal cable ducts or cable racks without

inducing significant current in the conductive metal connections (ground or leakage currents). The risk of

induced leakage currents and thus increased cable shield losses is signicantly higher with single-conductor

cables.

Loading...

Loading...