Start-Up

4-6

SINUMERIK 802C base line

Start-Up

4.2 Turning on and booting the control system

Procedure

z

Inspect the system visually for:

proper mechanical installation with tight electrical connections

supply voltages

connections for shielding and grounding.

z

Turn on the control system.

Notice

Providing memory and start–up switch S3 are set correctly (see Fig.2–6), the

control system boots.

Start–up switch S3 (hardware)

The CNC is provided with a start–up switch to assist start–up of the control

system.

This switch can be actuated using a screw driver.

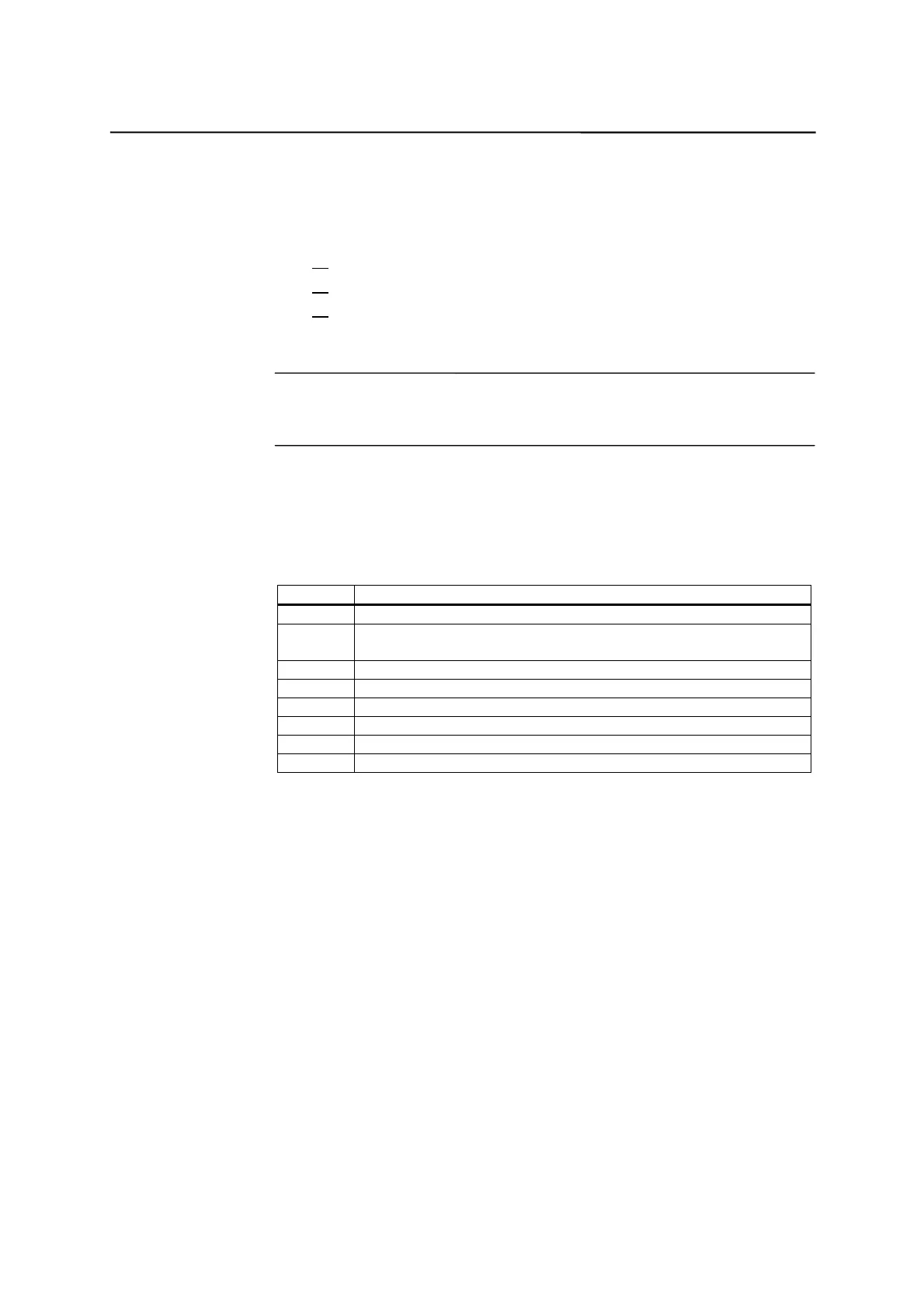

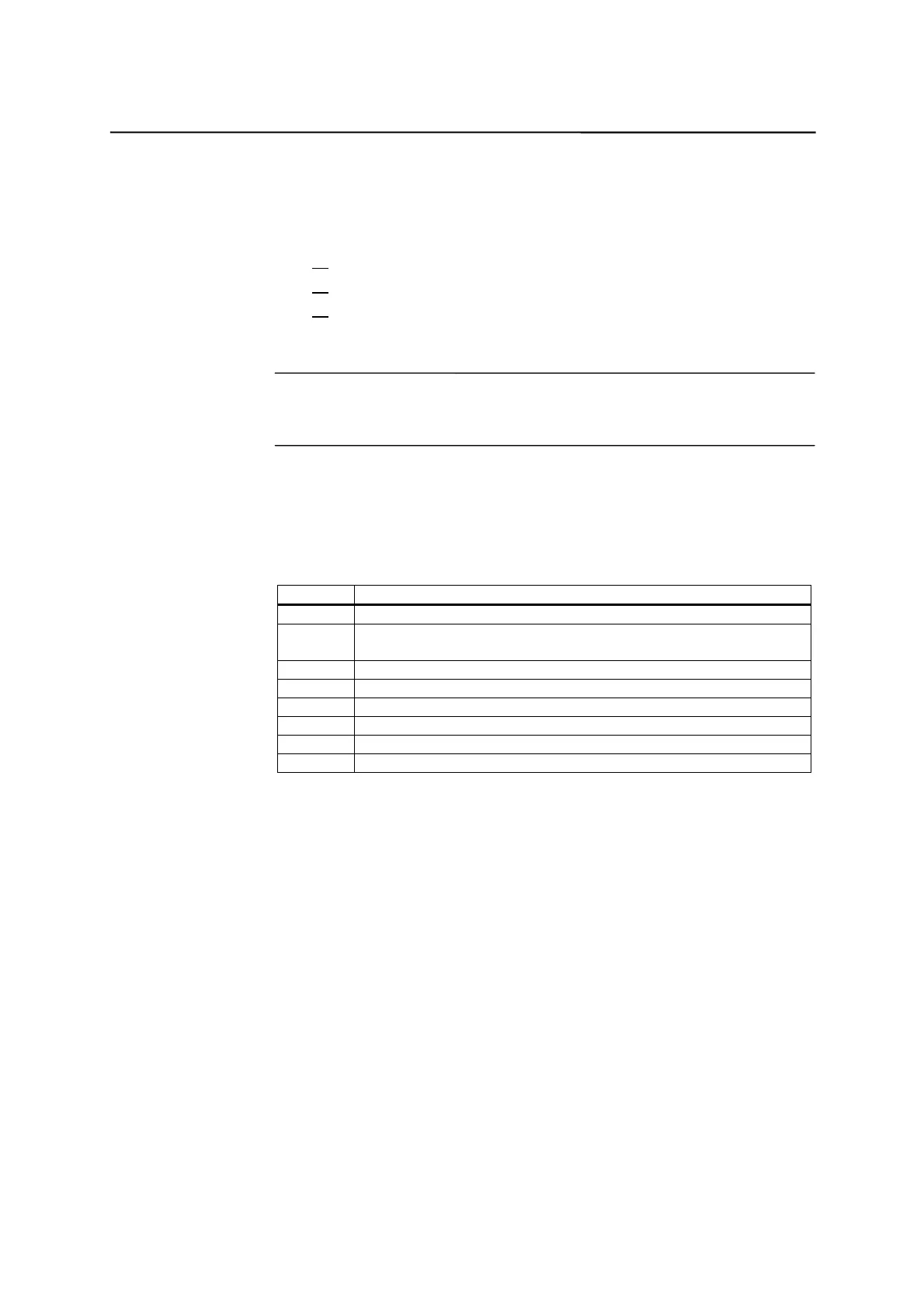

Table 4–2 Start–up switch settings

Position Meaning

0 Normal power-up

1 Power-up with default machine data (user data determined by the

software version)

2 System software update

3 Power-up with saved data

4PLC stop

5 Reserve

6 Assigned

7 Assigned

The switch position comes into effect with next power-up and is displayed on

the screen when the control system powers up.

Start–up switch

(software)

In addition to the hardware start–up switch, the following functions can also be

carried out in the Diagnosis/Start–up/Start–up switch menu:

z

Normal boot (Start–up switch position 0)

z

Boot with default machine data (Start–up switch position 1)

z

Boot with saved data (Start–up switch position 3)

These power-up functions have a higher priority than the hardware start-up

switch.

Booting the control system

When the control system is turned on for the first time, an initial state of the

control system is established automatically. All memory areas are initialized

and are loaded with previously stored default data.

The PLC area of retentive bit memories is explicitly erased.

Loading...

Loading...