Start-Up

4-18

SINUMERIK 802C base line

Start-Up

4.3.5 PLC programming

The PLC user program is created using the PLC 802 Programming Tool.

The Documentation “S7-200 Automation System, System Manual’’ describes

how this tool is operated for S7-200. The PLC 802 Programming Tool is to be

understood as a subset of this Documentation.

Compared with the S7-200 MicroWin basic system, please note the following:

z

The PLC 802 Programming Tool is delievered in the English language

version.

z

The user program can only be programmed using ladder diagram.

z

Only a subset of the S7-200 programming language is supported.

z

The compilation of the user program is carried out either offline on a

programming device (PG)PC or semi-automatically when downloading

into the control system.

z

The project can be loaded into the control system (download).

z

It is also possible to load the project from the control system (upload).

z

Direct data addressing is not possible; therefore, no programming errors

will result during the operation.

z

The data/process information must be managed by the user in

accordance with the particular type.

Example:

Information 1 T value DWord memory size (32-bit)

Information 2 Override Byte memory size (8-bit)

User data

Byte 0 DWord (Information 1)

Byte 4 Byte (Information 2)

The user is not allowed to access both of these data at the same time;

otherwise, the relevant data access rules must be observed.

Furthermore, the data direction in the memory model (alignment) and the data

type must be observed for all data.

Example:

Flag bit MB0.1,MB3.5

Flag byte MB0,MB1,MB2

Flag word MW0,MW2,MW4

MW3, MW5 ... are not permissible

Flag double-word MD0,MD4,MD8

MD1,MD2,MD3, MD5 ... are not permissible

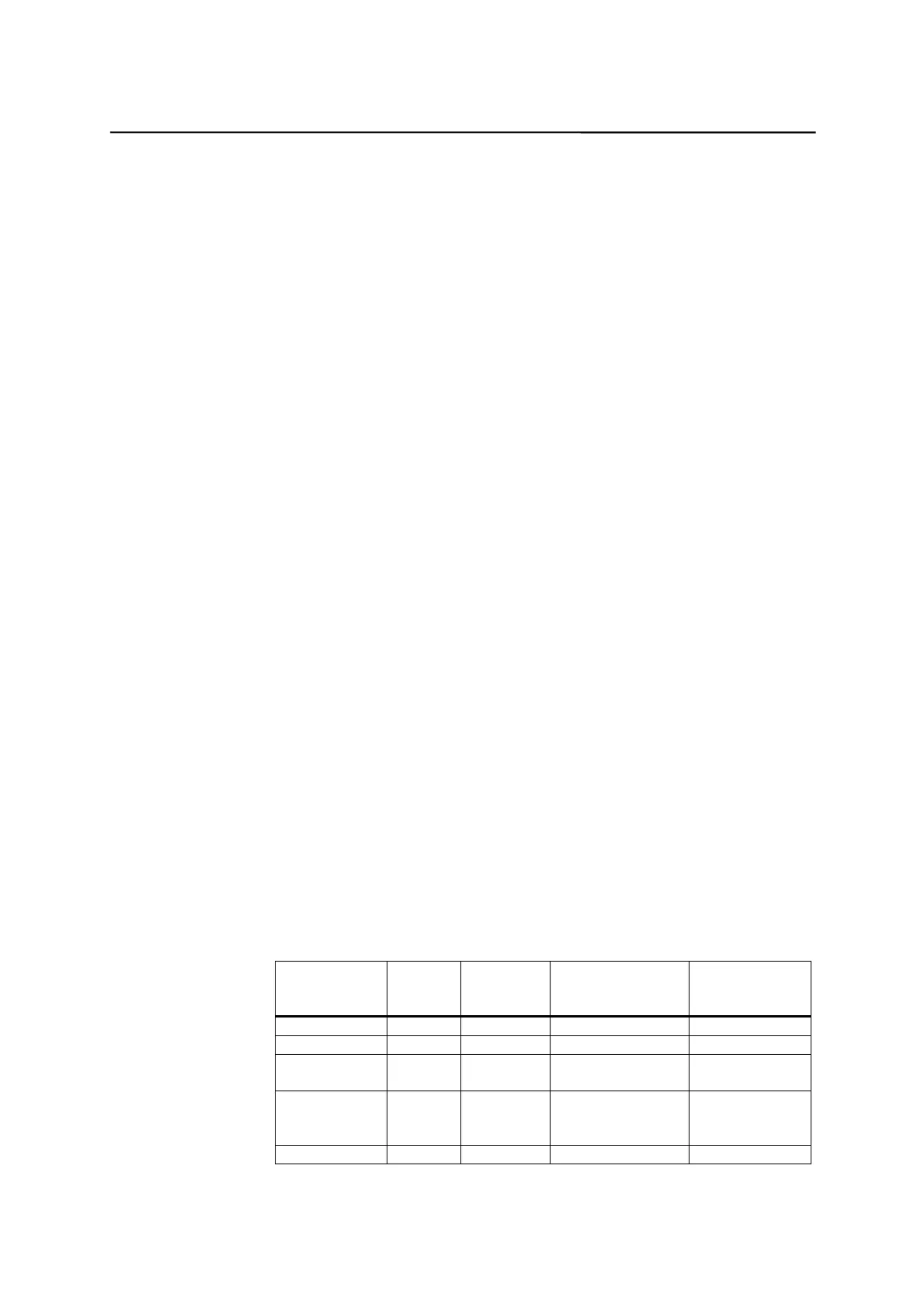

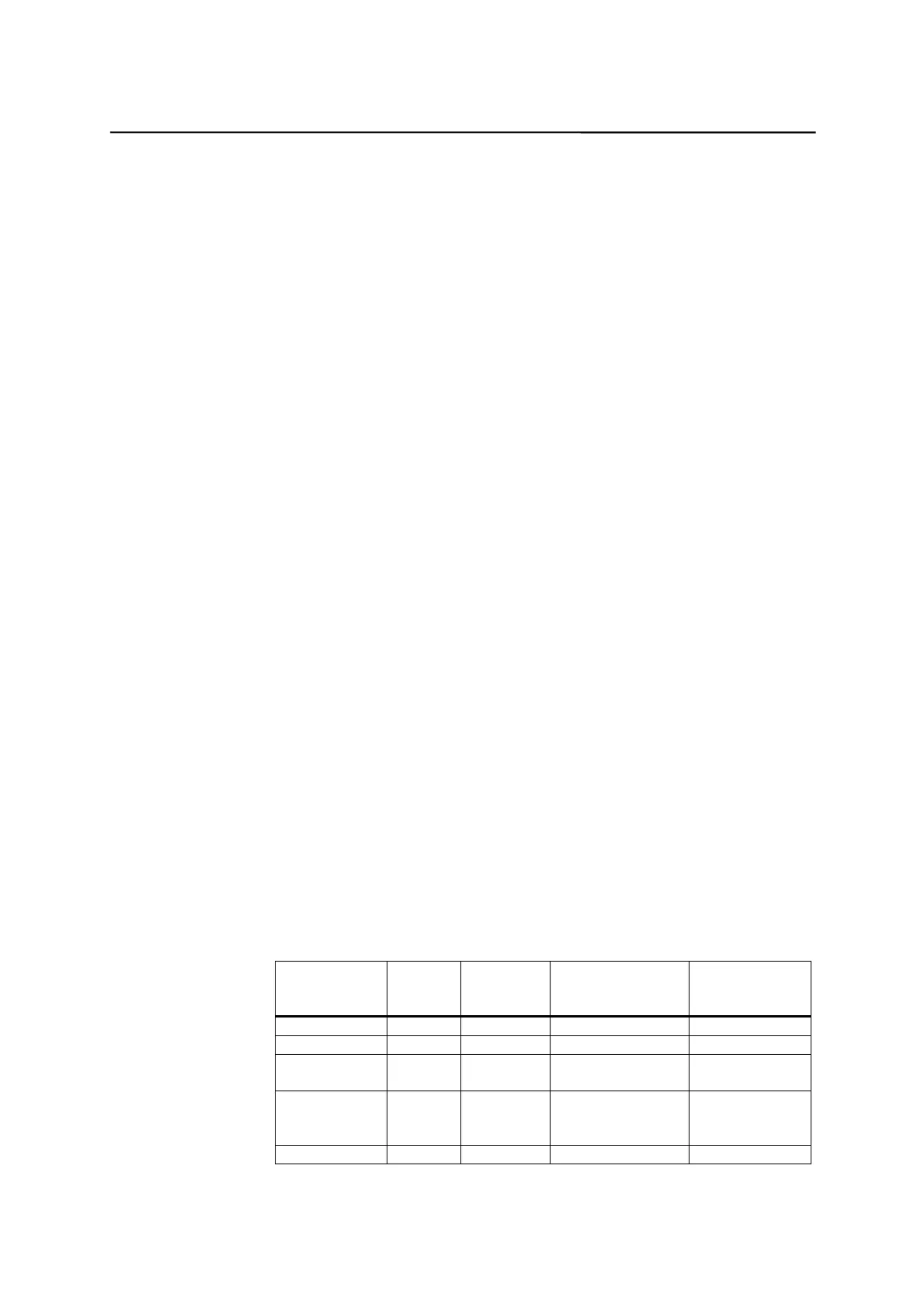

Table 4–6 PLC data types permitted in the control system

Data Type Size

Address

Alignment

Range for

Logic Operations

Range for

Arithmetical

Operations

BOOL 1 bit 1 0, 1 -

BYTE 1 byte 1 00 ... FF 0 ... +255

WORD 2 bytes 2 0000 ... FFFF -32 768 ... + 32

767

DWORD

(Double Word)

4 bytes 4 0000 0000 ...

FFFF FFFF

-2 147 483

648 ...

+2 147 483 647

REAL 4 bytes 4 - +/-10

-37

... +/-10

38

Loading...

Loading...