Start-Up

4.7 Commissioning

4-97

SINUMERIK 802S

6FC5 597–2AA00–0BP2 (01.02)

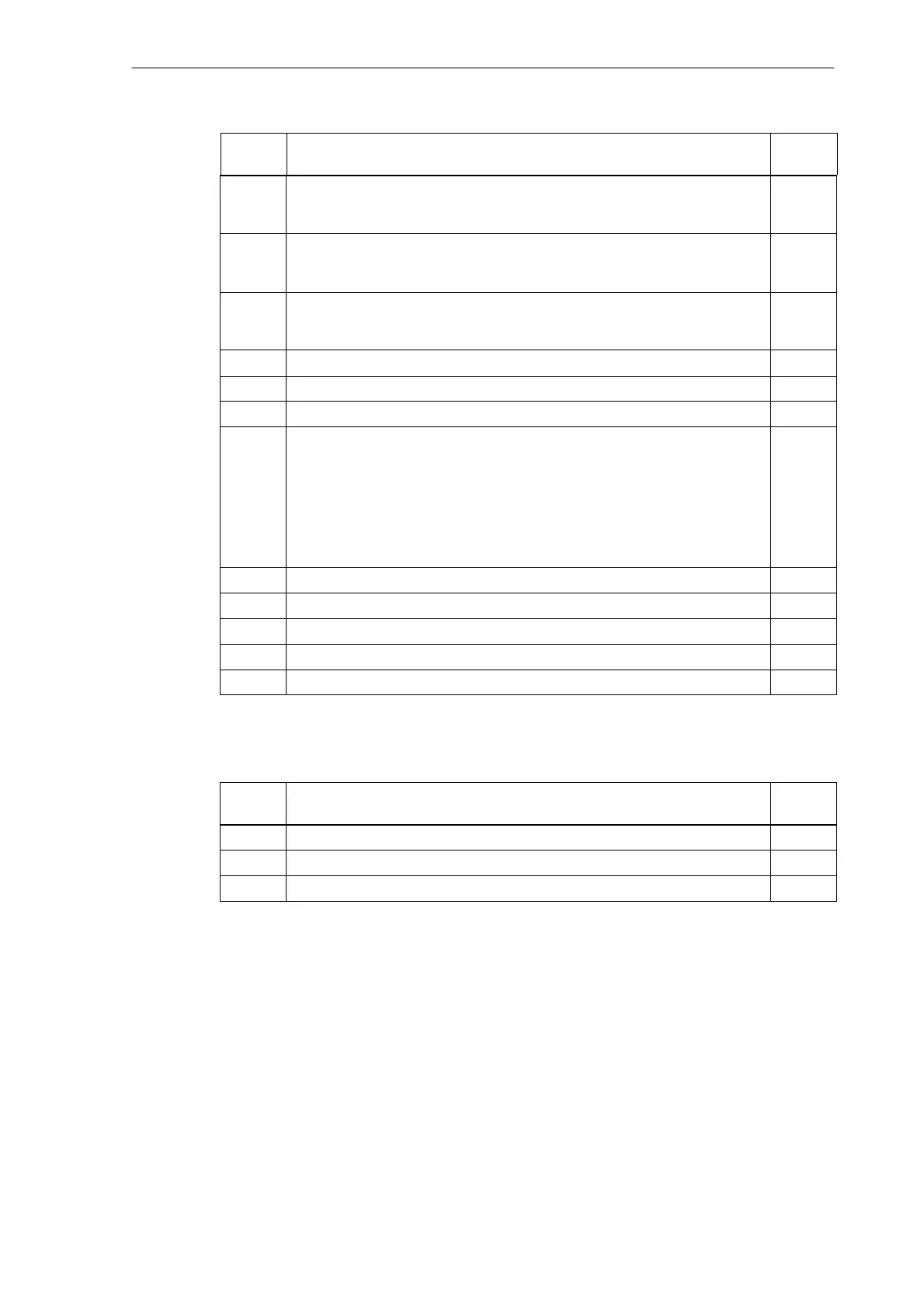

Number

Default

Value

Explanation

36040

(only

SPOS)

Delay zero-speed monitoring

0.4

36050

(only

SPOS)

Clamping tolerance

0.5

36060

(only

SPOS)

Maximum velocity/speed ”axis/spindle stopped”

0,0138

36200 Threshold value for velocity monitoring (control parameter set no.): 0...5 31,94

36300 Encoder limit frequency 300000

36302 Encoder limit frequency at which encoder is switched on again. (Hysteresis) 99.9

36310

Zero mark monitoring (encoder no.):

0,1 0: Zero mark monitoring off, encoder

HW monitoring on

1-99, >100: Number of recognized zero mark errors

during monitoring

100: Zero mark monitoring off, encoder

HW monitoring off

0

36610 Duration of the deceleration ramp for error states 0.05

36620 Cutout delay servo enable 0.1

36700 Automatic drift compensation 0

36710 Drift limit value for automatic drift compensation 1

36720 Drift basic value 0

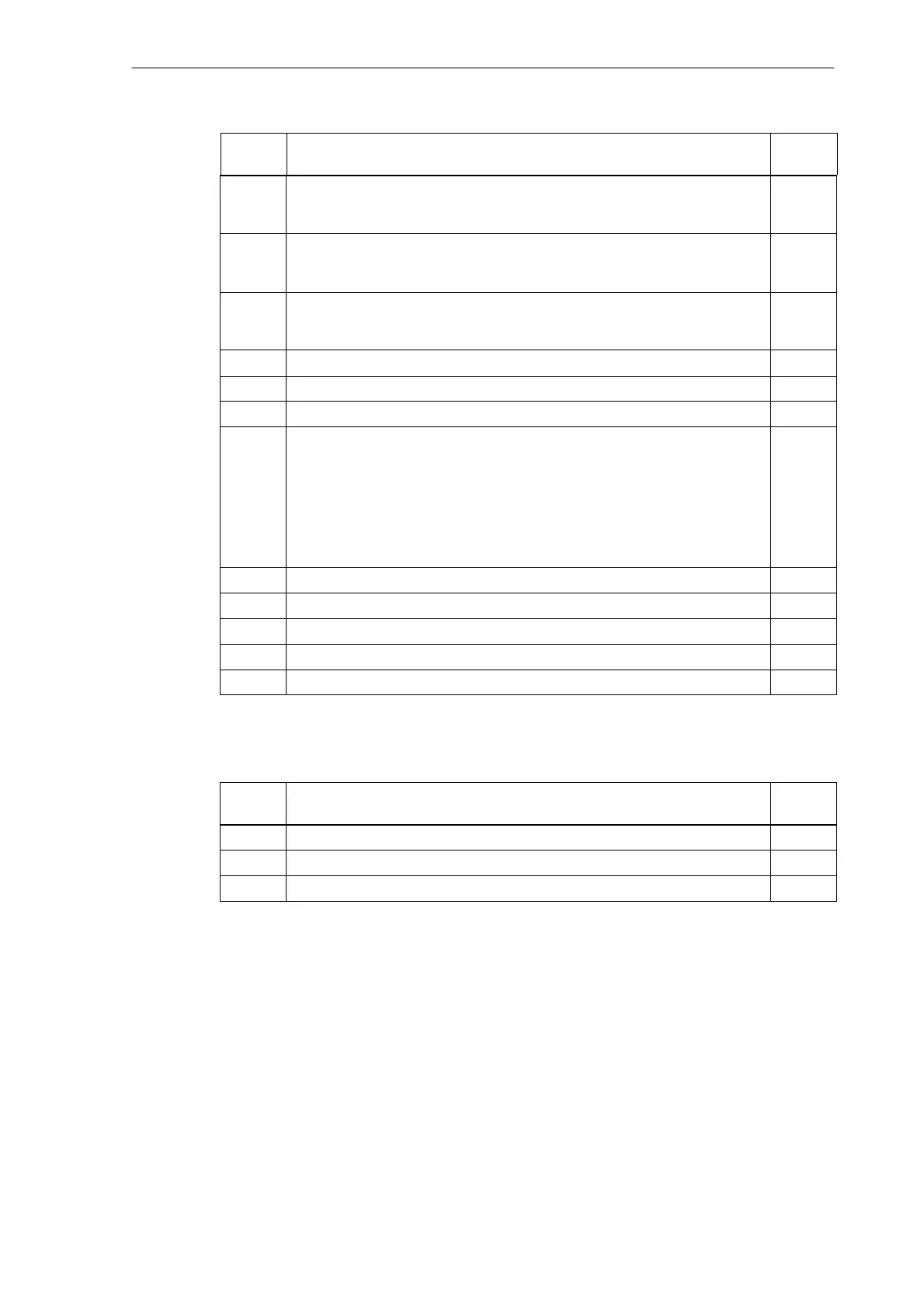

SD for spindle

Number Explanation

Default

Value

43210 Progr. spindle speed limitation G25 0

43220 Progr. spindle speed limitation G26 1000

43230 Spindle speed limitation with G96 100

Spindle MD parameterization

Spindle machine data are entered depending on the gear stages. Each gear stage is assigned

a parameter set.

The set of parameters selected corresponding to the current gear stage.

Example: 1st gear stage set of parameters [1]

Loading...

Loading...