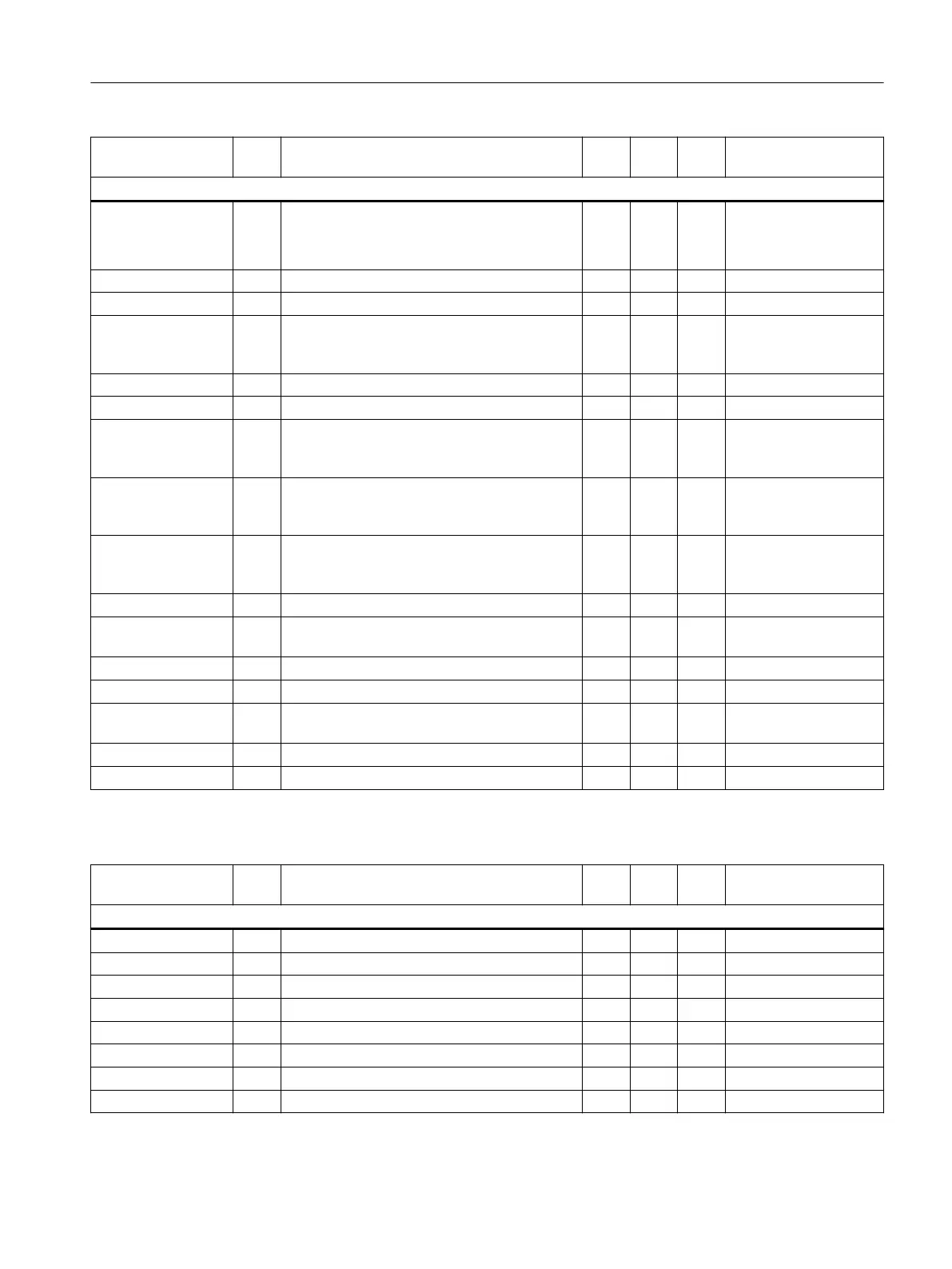

Operation Type

1)

Meaning W

2)

TP

3)

SA

4)

Description see

5)

1) 2) 3) 4) 5)

for explanations, see legend (Page 1197).

LEAD A Lead angle

1st basic tool orientation

2nd orientation polynomials

m + PM-NC

LEADOF P Axial master value coupling OFF + + PM-NC

LEADON P Axial master value coupling on + + PM-NC

LENTOAX F Provides information about the assignment of

tool lengths L1, L2, and L3 of the active tool to

the abscissa, ordinate and applicate

+ - PM-NC

LFOF

6)

G Fast retraction for thread cutting OFF m + PM-NC

LFON G Fast retraction for thread cutting ON m + PM-NC

LFPOS G Retraction of the axis declared with POLF‐

MASK or POLFMLIN to the absolute axis po‐

sition programmed with POLF

m + PM-NC

LFTXT

6)

G The plane of the retraction movement for fast

retraction is determined from the path tangent

and the current tool direction

m + PM-NC

LFWP G The plane of the retraction movement for fast

retraction is determined by the current work‐

ing plane (G17/G18/G19)

m + PM-NC

LIFTFAST K Fast retraction + PM-NC

LIMS K Speed limitation

for G96/G961 and G97

m + PM-NC

LLI K Lower limit value of variables + PM-NC

LN F Natural logarithm + + PM-NC

LOCK P Disable synchronous action with ID

(stop technology cycle)

- + FM-SA

LONGHOLE C (T) Elongated hole + PM-NC

LOOP K Introduction of an endless loop + PM-NC

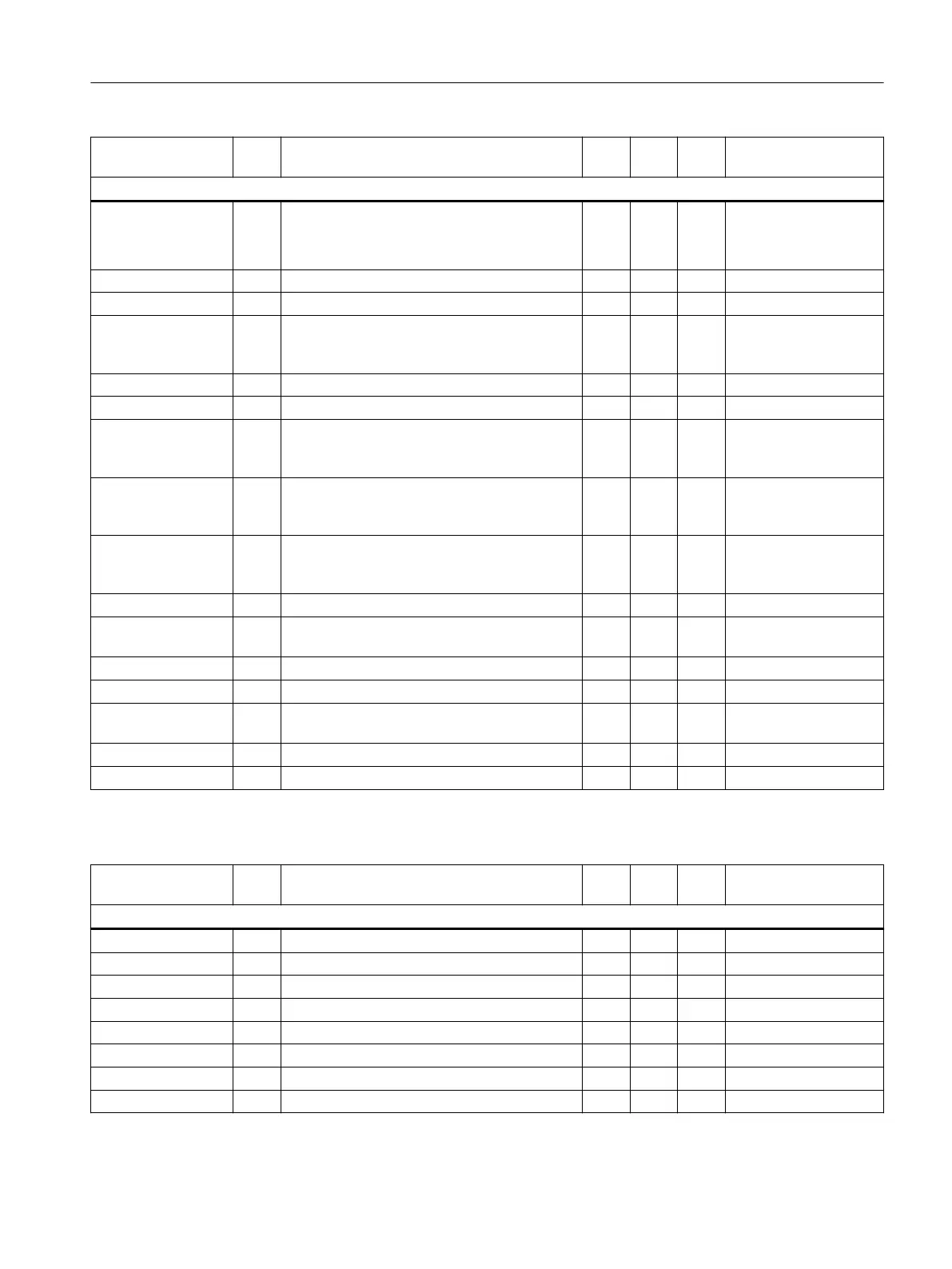

Operations M ... R

Operation Type

1)

Meaning W

2)

TP

3)

SA

4)

Description see

5)

1) 2) 3) 4) 5)

for explanations, see legend (Page 1197).

M0 Programmed stop + + PM-NC

M1 Optional stop + + PM-NC

M2 End of program, main program (as M30) + + PM-NC

M3 CW spindle rotation + + PM-NC

M4 CCW spindle rotation + + PM-NC

M5 Spindle stop + + PM-NC

M6 Tool change + + PM-NC

M17 End of subprogram + + PM-NC

Tables

4.1 Operations

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 1219

Loading...

Loading...