With the new behavior (bit 0 = 1), the data storage in the PLC consists of max. 8 bytes

(DBB 208 - DBB 215).

With this procedure, the array index of this byte array is identical with the index of

the MD22510 $MC_GCODE_GROUPS_TO_PLC[Index] and MD22512

$MC_EXTERN_GCODE_GROUPS_TO_PLC[Index].

Each index (0 - 7) may only be set for one of the two machine data; the value 0 must

be entered for the other MD.

Bit 0(LSB) = 0:

Behavior as before, the 64-byte field is used for displaying the G codes

Bit 0(LSB) = 1:

The user specifies for which G groups the first 8 bytes are to be used

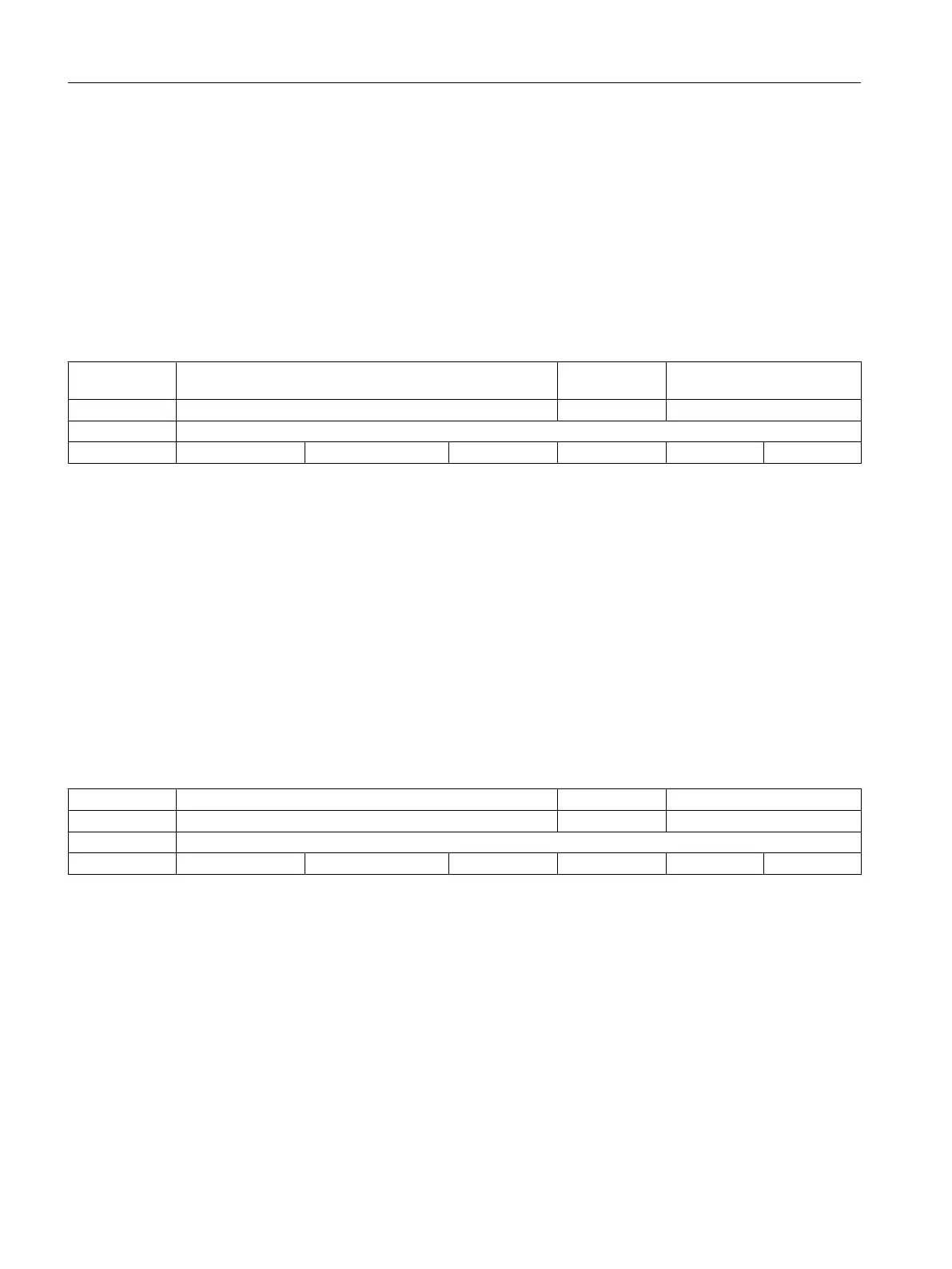

22550 TOOL_CHANGE_MODE C01, C11, C04,

C09

W3, K1, W1

- New tool compensation for M function BYTE PowerOn

-

- - 0, 0, 0, 0, 0, 0, 0, 0... 0 1 2/2 M

Description: The T function is used to select a tool in the program. The setting in this machine

data determines whether the new tool is loaded immediately on execution of the T

function:

MD22550 $MC_TOOL_CHANGE_MODE = 0

The new tool is loaded directly with the programming of T or D. This setting is mainly

used on turning machines. If a D is not programmed in the block by T, then the tool

offset defined in MD20270 $MC_CUTTING_EDGE_DEFAULT is active.

In this case, the function "Manual tools" is not enabled.

MD22550 $MC_TOOL_CHANGE_MODE = 1

The new tool is prepared for loading on execution of the T function. This setting is

used mainly on milling machines with a tool magazine in order to bring the new tool

into the tool change position without interrupting the machining process. The M

function entered in MD22560 $MC_ TOOL_CHANGE_M_CODE is used to remove the old tool

from

the spindle

and load the new tool onto the spindle. According to DIN 66025, this

tool change has to be programmed with M function M06.

Related to:

MD22560 $MC_TOOL_CHANGE_M_CODE

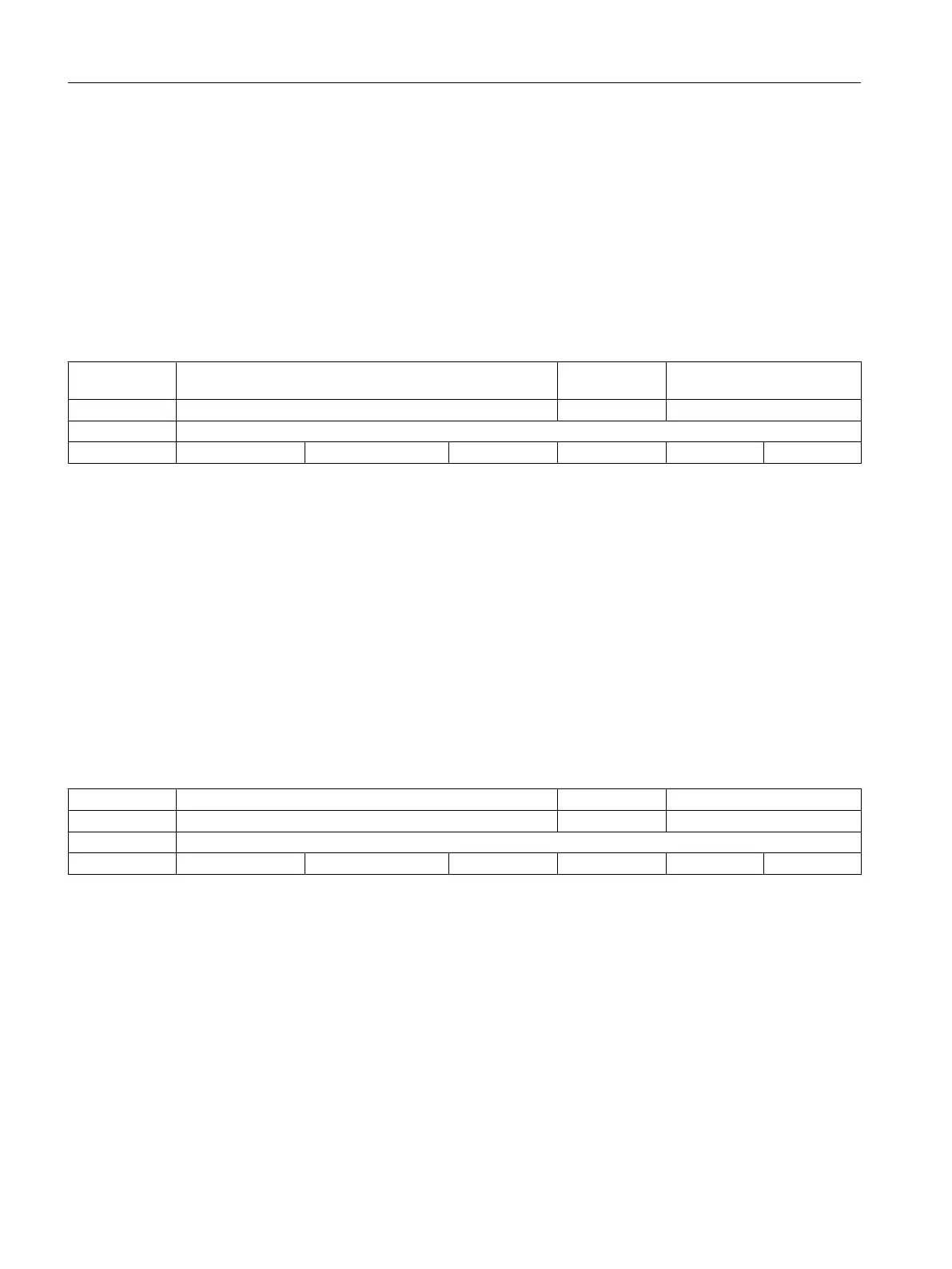

22560 TOOL_CHANGE_M_CODE C01, C04, C09 H2, K1, W1

- M function for tool change DWORD PowerOn

-

- - 6, 6, 6, 6, 6, 6, 6, 6... 6 99999999 1/1 M

Description: If the T function is only used to prepare a new tool for a tool change (this setting

is used mainly

on milling machines with a tool magazine, in order to bring the new tool

into the tool change position without interrupting the machining process), another M

function must be used to trigger the tool change.

The M function entered in TOOL_CHANGE_M_CODE triggers the tool change (remove old tool

from the spindle

and load new tool into the spindle). This tool change is required to

be programmed with M function M06, in accordance with DIN 66025.

Related to:

MD22550 $MC_TOOL_CHANGE_MODE

Machine data

3.3 Channel-specific machine data

Parameter Manual

172 Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1

Loading...

Loading...