b. Specifically for SINAMICS drives, if inversion of the encoder signal is

parameterized in MD32110 $MA_ENC_FEEDBACK_POL=-1 with active DSC. Remedy: Remove

inversion of the encoder signal from MD32110 $MA_ENC_FEEDBACK_POL, and enter it in

SINAMICS parameter P410 instead.

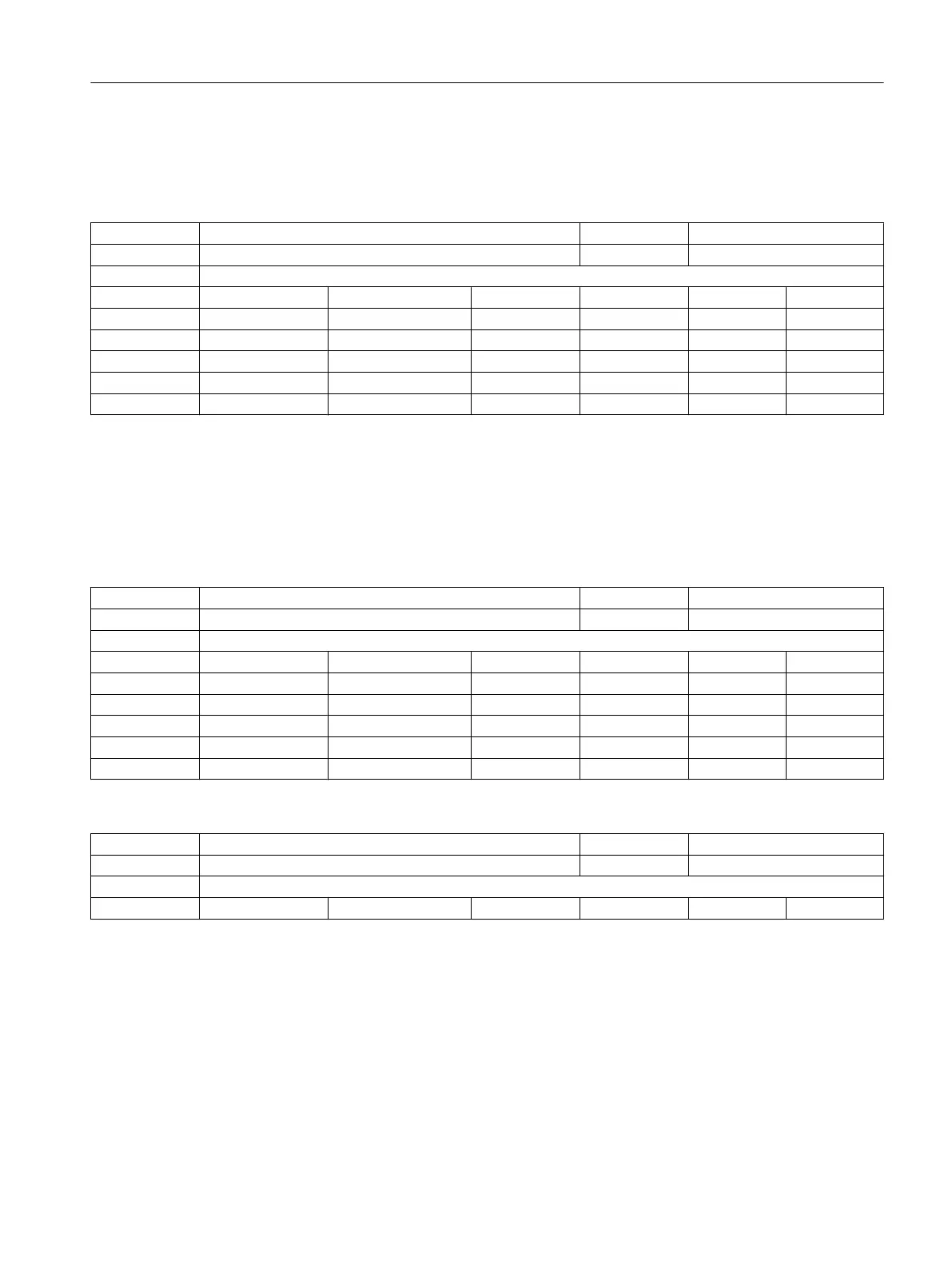

32642 STIFFNESS_CONTROL_CONFIG A01, A07 -

- Dynamic stiffness control configuration (DSC) BYTE NEW CONF

CTEQ

808d-me42 1 0 0 1 ReadOnly

808d-me62 1 0 0 1 1/1

808d-te42 1 0 0 1 ReadOnly

808d-te62 1 0 0 1 1/1

808d-mte40 1 0 0 1 7/2

808d-mte60 1 0 0 1 7/2

Description: Configuration of the dynamic stiffness control (DSC):

0: DSC in drive works with indirect measuring system, i.e. motor measuring system

(default scenario).

1: DSC in drive works with direct measuring system.

Notes:

The availability of this function is determined by the drive used (the drive must

support the DSC function).

With SINAMICS (P1193 not equal to 0), the value of this machine data must be set to 0.

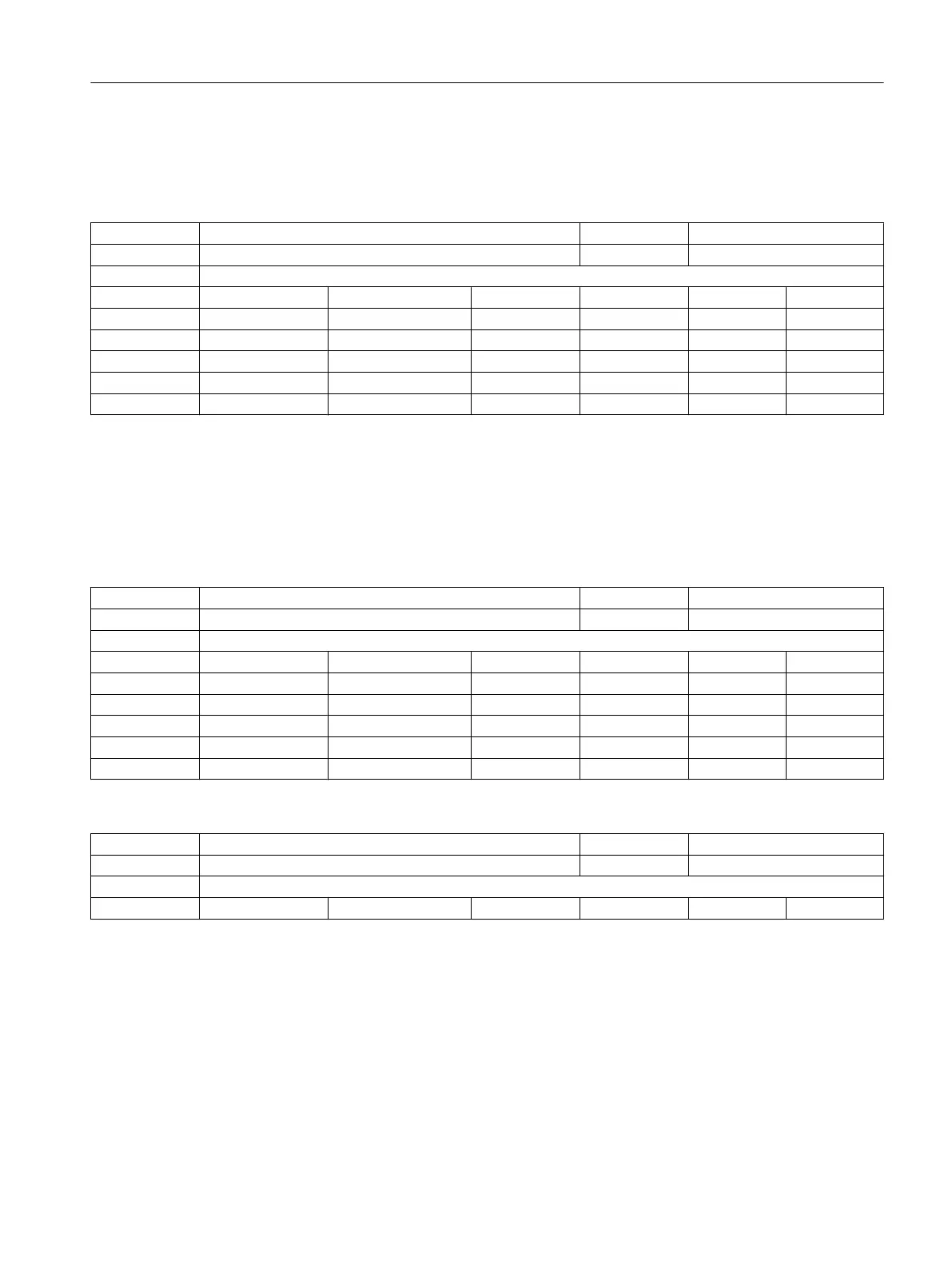

32644 STIFFNESS_DELAY_TIME A01, A07 -

s Dynamic stiffness control: Delay DOUBLE PowerOn

CTEQ

808d-me42 1 0.0 -0.02 0.02 ReadOnly

808d-me62 1 0.0 -0.02 0.02 1/1

808d-te42 1 0.0 -0.02 0.02 ReadOnly

808d-te62 1 0.0 -0.02 0.02 1/1

808d-mte40 1 0.0 -0.02 0.02 7/2

808d-mte60 1 0.0 -0.02 0.02 7/2

Description: Configuration of compensation dead time of the dynamic stiffness control (DSC) with

optimized PROFIBUS/PROFINET cycle, unit: seconds

32700 ENC_COMP_ENABLE A09 K3

- Encoder/spindle error compensation. BOOLEAN NEW CONF

-

- 1 FALSE, FALSE 0 - 2/2

Description: 1: LEC (leadscrew error compensation) is activated for the measuring system.

This enables leadscrew and measuring system errors to be compensated.

The function is not enabled internally until the relevant measuring system has been

referenced (NC/PLC interface signal DB390x DBX0.4 / .5 (Referenced/synchronized 1 or

2) = 1).

write protect function (compensation values) active.

0: LEC is not active for the axis/measuring system.

Related to:

MD38000 $MA_MM_ENC_COMP_MAX_POINTS number of interpolation points with LEC

NC/PLC interface signal DB390x DBX0.4 (Referenced/synchronized 1)

NC/PLC interface signal DB390x DBX0.5 (Referenced/synchronized 2)

Machine data

3.4 Axis-specific machine data

Parameter Manual

Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1 249

Loading...

Loading...