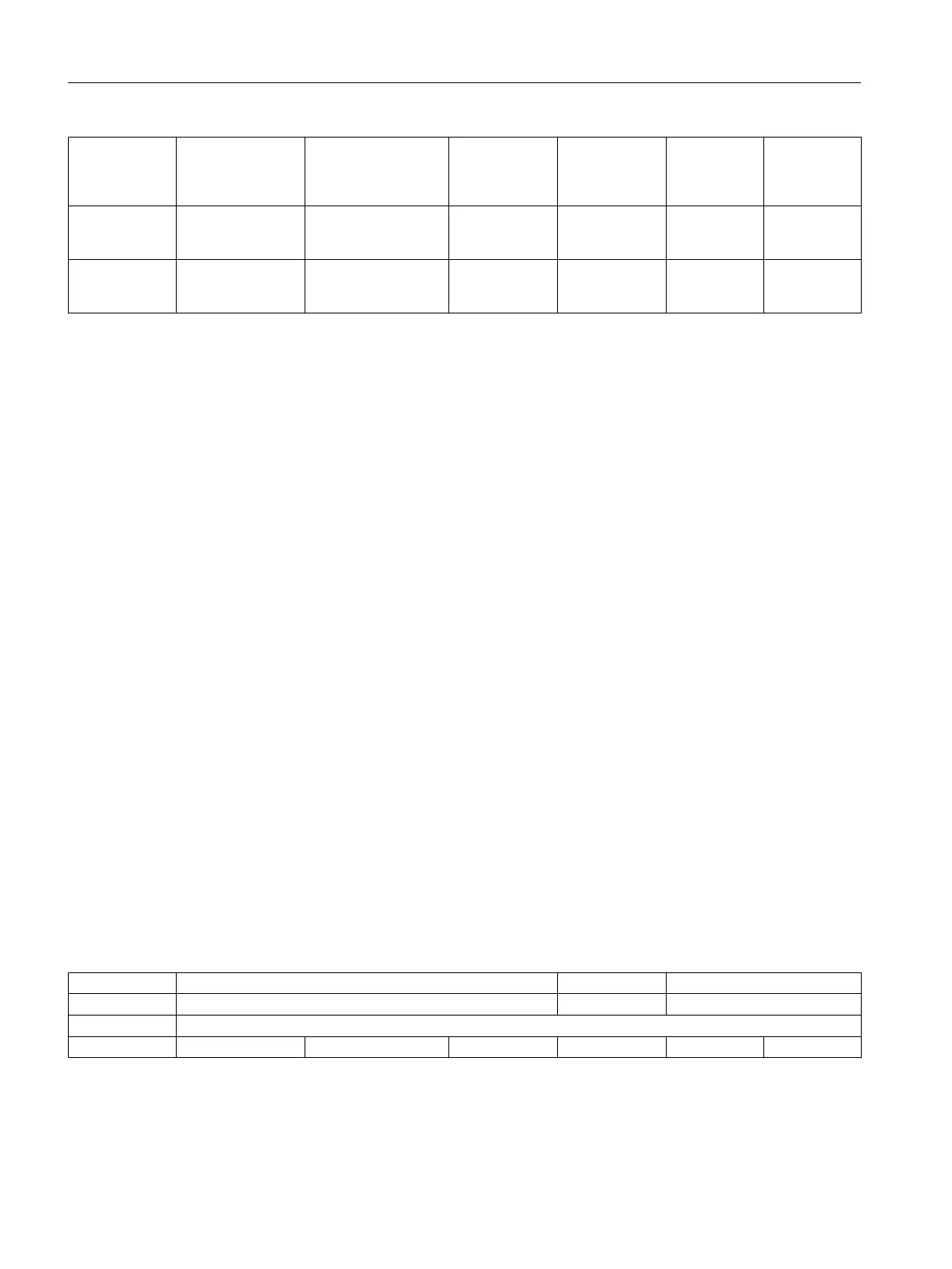

808d-te62 1 300.00, 300.00,

300.00, 300.00,

300.00, 300.00,

720.00, 720.00, ...

(0./ 0.) (1.e300/ 1.e300) 2/2

808d-mte40 1 (300.0/ 300.0)/ (10.0/

10.0), (300.0/ 300.0)/

(10.0/ 10.0), (300...

(0./ 0.) (1.e300/ 1.e300) 2/2

808d-mte60 1 (300.0/ 300.0)/ (10.0/

10.0), (300.0/ 300.0)/

(10.0/ 10.0), (300...

(0./ 0.) (1.e300/ 1.e300) 2/2

Description: 1) For incremental measuring systems:

This is the velocity at which the axis travels during the time between initial

detection of the

reference cam and synchronization with the first zero mark (phase 2).

Traversing direction: Opposite to the direction specified for the cam search (MD34010

$MA_REFP_CAM_DIR_IS_MINUS)

If MD34050 $MA_REFP_SEARCH_MARKER_REVERSE (direction reversal on reference cam) is

enabled, then if the axis is synchronized with a rising reference cam signal edge on

the cam, the axis traverses at the velocity defined in MD34020

$MA_REFP_VELO_SEARCH_CAM.

2) Indirect measuring system with BERO on the load-side (preferred for spindles):

At this velocity, a search is made for the zero mark associated with the BERO (zero

mark

selection per

VDI signal). The zero mark is accepted if the actual velocity lies

within the tolerance range defined in MD35150 $MA_SPIND_DES_VELO_TOL as a deviation

from the velocity specified in MD34040 $MA_REFP_VELO_SEARCH_MARKER[n].

3) For linear measuring systems with distance-coded reference marks:

The axis crosses the two reference marks at this velocity. The maximum velocity must

be low enough to ensure that the time required to travel the smallest possible

reference mark distance [(x(minimum)] on the linear measuring system is longer than

one position controller cycle.

The formula

Basic dist. Meas.length

[x(minimum)] [mm] = ----------- * Grad.cycle - --------------

2 Basic dist.

with Basic distance [multiple of graduation cycle]

Graduation cycle [mm]

Measuring length [mm] yields:

x(minimum) [mm]

max. velocity [m/s] = ---------------------------------

Position controller cycle [ms]

This limiting value consideration also applies to the other measuring systems.

Traversing direction:

● as defined in MD34010 $MA_REFP_CAM_DIR_IS_MINUS;

● if

the axis

is already positioned on the cam, the axis is traversed in the opposite

direction

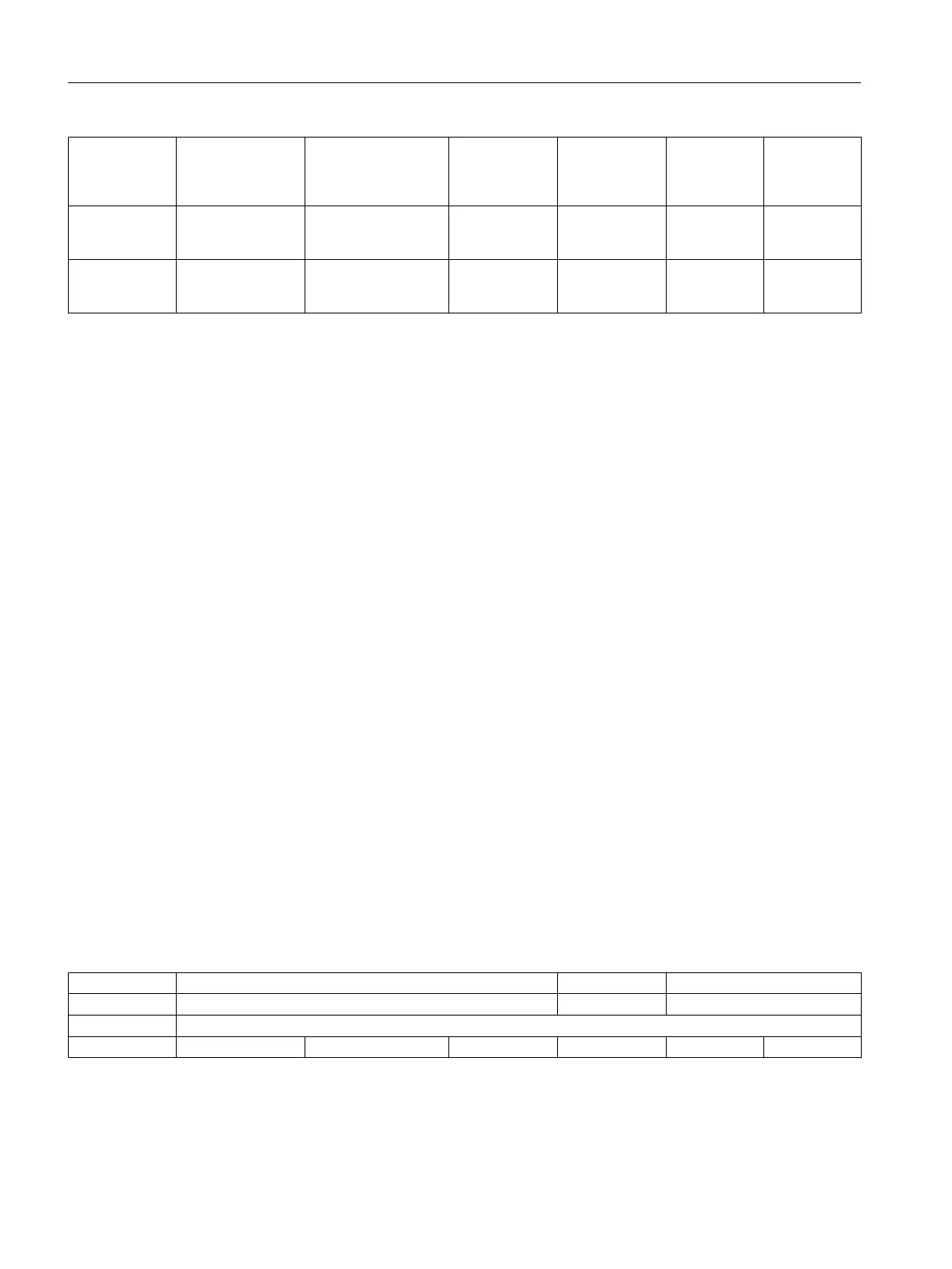

34050 REFP_SEARCH_MARKER_REVERSE A03, A11 G1, R1

- Direction reversal to reference cam BOOLEAN Reset

-

- 1 FALSE, FALSE 0 - 2/2

Description: This MD can be used to set the direction of search for the zero mark:

MD34050 $MA_REFP_SEARCH_MARKER_REVERSE = 0

Synchronization with falling reference cam signal edge

Machine data

3.4 Axis-specific machine data

Parameter Manual

258 Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1

Loading...

Loading...