Description: ● Incremental encoder with zero mark(s):

The position value

which is set as the current axis position after detection of the

zero mark and traversal of the distance REFP_MOVE_DIST + REFP_MOVE_DIST_CORR

(relative to zero mark). REFP_SET_POS of the reference point number, which is set

at the instant that the edge of the reference cam signal rises (NC/PLC interface

signal DB380x DBX2.4 - .7 (Reference point value 1 to 4)), is set as the axis

position.

● Distance-coded measuring system:

Target position which is approached when MD34330 $MA_REFP_STOP_AT_ABS_MARKER is set to

0 (FALSE) and two zero marks have been crossed.

● Absolute encoder:

MD34100 $MA_REFP_SET_POS corresponds to the correct actual value at the calibration

position.

The reaction on the machine depends on the status of MD34210 $MA_ENC_REFP_STATE: When

MD34210 $MA_ENC_REFP_STATE = 1, the value of MD34100 $MA_REFP_SET_POS is transferred

as the absolute value.

When MD34210 $MA_ENC_REFP_STATE = 2 and MD34330 $MA_REFP_STOP_AT_ABS_MARKER = 0

(FALSE), the axis approaches the target position stored in MD34100 $MA_REFP_SET_POS.

The value of MD34100 $MA_REFP_SET_POS that has been set via NC/PLC interface signal

DB380x DBX2.4 - .7 (Reference point value 1 to 4) is used.

Related to:

NC/PLC interface signal DB380x DBX2.4 - .7 (Reference point value 1 to 4)

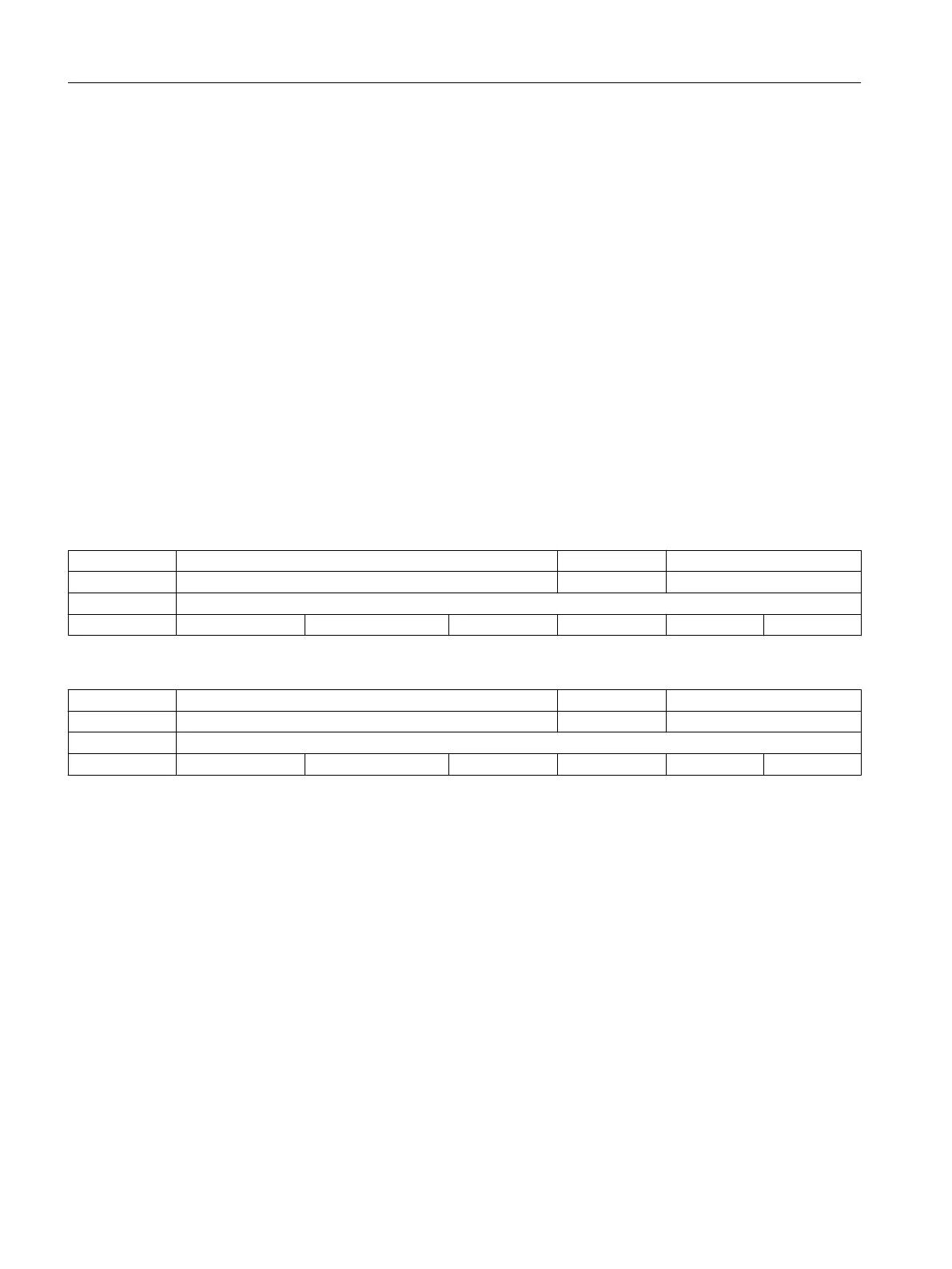

34104 REFP_PERMITTED_IN_FOLLOWUP A03, A02 R1

- Enable referencing in follow-up mode BOOLEAN Reset

-

- - FALSE 0 - 1/1

Description: An axis can also be referenced in the follow-up mode under JOG+REF mode by means of an

external motion.

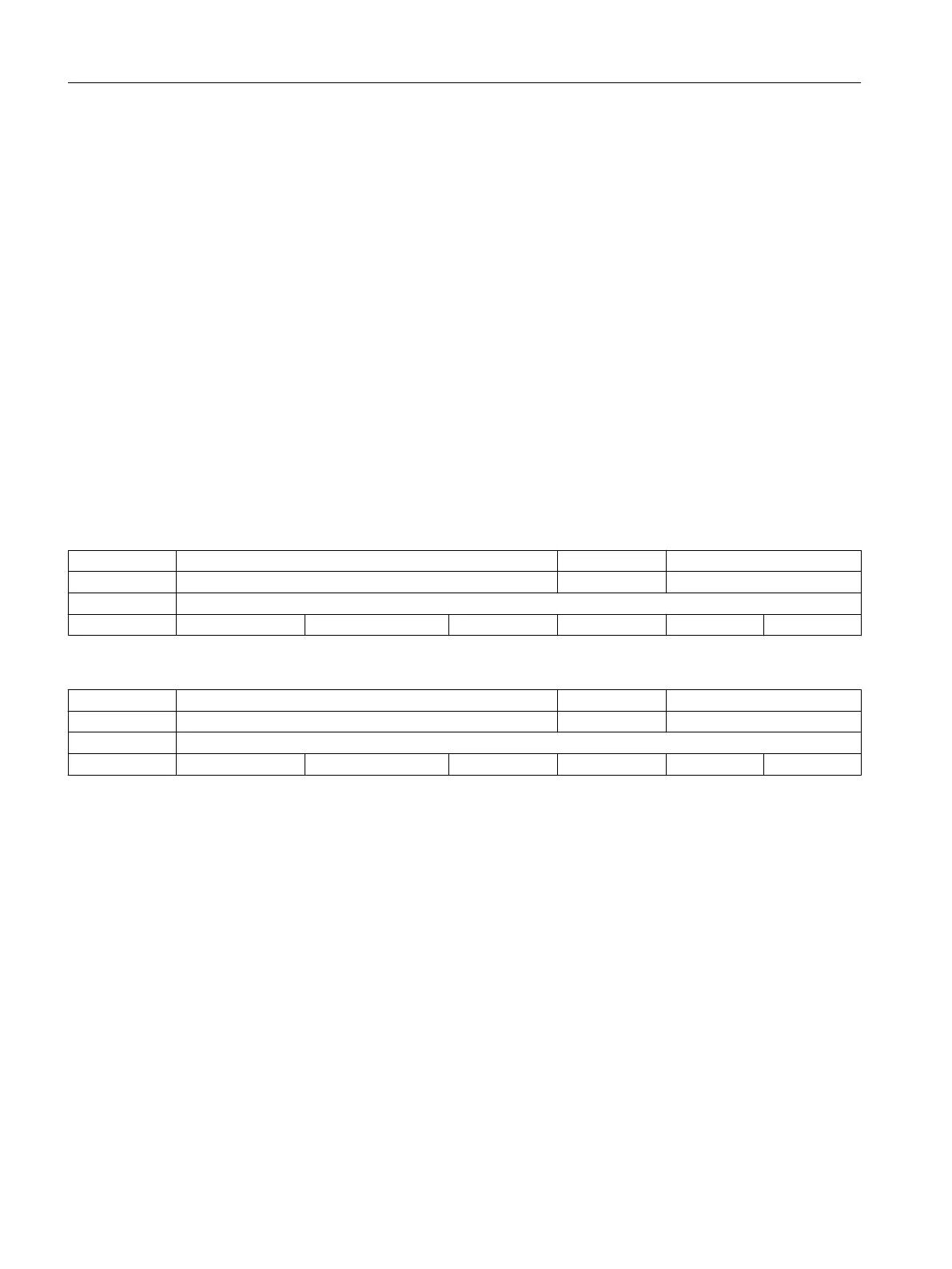

34110 REFP_CYCLE_NR A03 G1, TE3, D1, R1, Z1

- Sequence of axes in channel-specific referencing DWORD PowerOn

-

- - 1, 2, 3, 4, 5, 6, 7, 8... -1 31 2/2

Description: MD34110 $MA_REFP_CYCLE_NR = 0 -----> axis-specific referencing

Axis-specific referencing is started separately for each machine axis with the NC/PLC

interface signal DB380x DBX4.7 / 4.6 (Plus/minus travel keys).

Up to 8 axes (840D) can be referenced simultaneously.

The following alternatives are provided for referencing the machine axes in a specific

sequence:

● The operator has to observe the correct sequence on startup.

● The PLC checks the sequence on startup or defines the sequence itself.

● The channel-specific referencing function is used.

MD34110 $MA_REFP_CYCLE_NR = 1 -----> channel-specific referencing

Channel-specific referencing is started with the NC/PLC interface signal DB3200 DBX1.0

(Activate referencing). The control acknowledges a successful start with the NC/PLC

interface

signal DB3300

DBX1.0 (Referencing active). Each machine axis assigned to the

channel can be referenced with channel-specific referencing (this is achieved

internally on the control by simulating the plus/minus traversing keys). The axis-

specific MD34110 $MA_REFP_CYCLE_NR can be used to define the sequence in which the

machine axes are referenced:

-1 means:

The machine axis is not started by channel-specific referencing, and NC start is

possible without referencing this axis.

Machine data

3.4 Axis-specific machine data

Parameter Manual

262 Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1

Loading...

Loading...