● Thread-cutting (G33, G34, G35)

● Revolutional feedrate (G95, G96, G97, FPRAON)

● Display of actual position and velocity, or speed respectively.

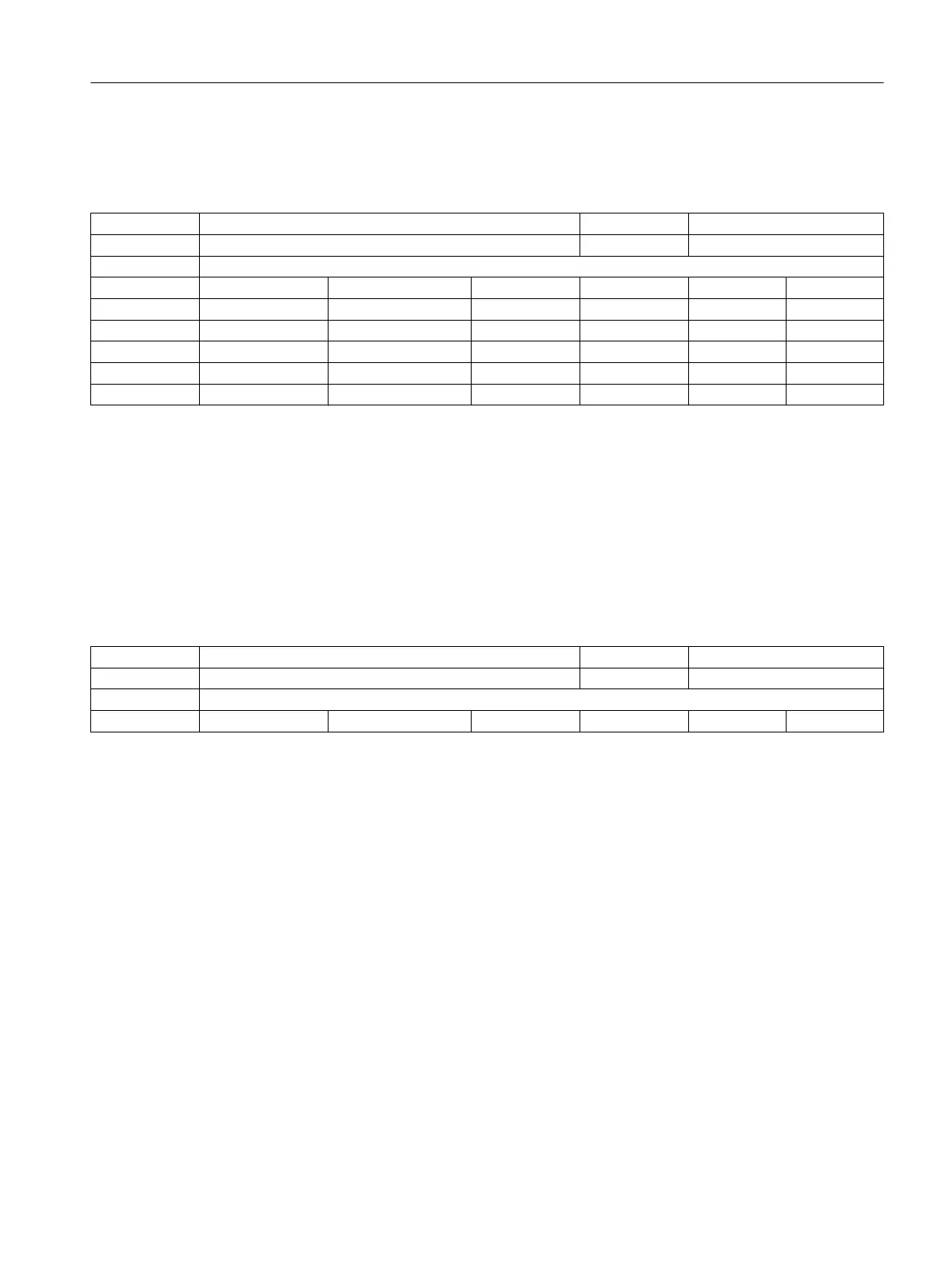

35000 SPIND_ASSIGN_TO_MACHAX A01, A06, A11 M1, S3, K2, S1

- Assignment of spindle to machine axis BYTE PowerOn

-

808d-me42 - 0, 0, 0, 1 0 20 1/1

808d-me62 - 0, 0, 0, 1 0 20 1/1

808d-te42 - 0, 0, 0, 1 0 20 1/1

808d-te62 - 0, 0, 0, 1 0 20 1/1

808d-mte40 - 0, 0, 0, 0, 0, 0, 0, 0... 0 20 1/1

808d-mte60 - 0, 0, 0, 0, 0, 0, 0, 0... 0 20 1/1

Description: Spindle definition. The spindle is defined when the spindle number has been entered in

this MD.

Example:

If the corresponding axis is to be spindle 1, value "1" must be entered in this MD.

The spindle functions are possible only for modulo rotary axes. For this purpose

MD30300 $MA_IS_ROT_AX and MD30310 $MA_ROT_IS_MODULO must be set.

The axis functionality is maintained; transition to axis operation can be performed

with M70.

The lowest spindle number is 1, the highest number depends on the number of axes in

the channel.

If other spindle numbers are to be assigned, the function "spindle converter" must be

used.

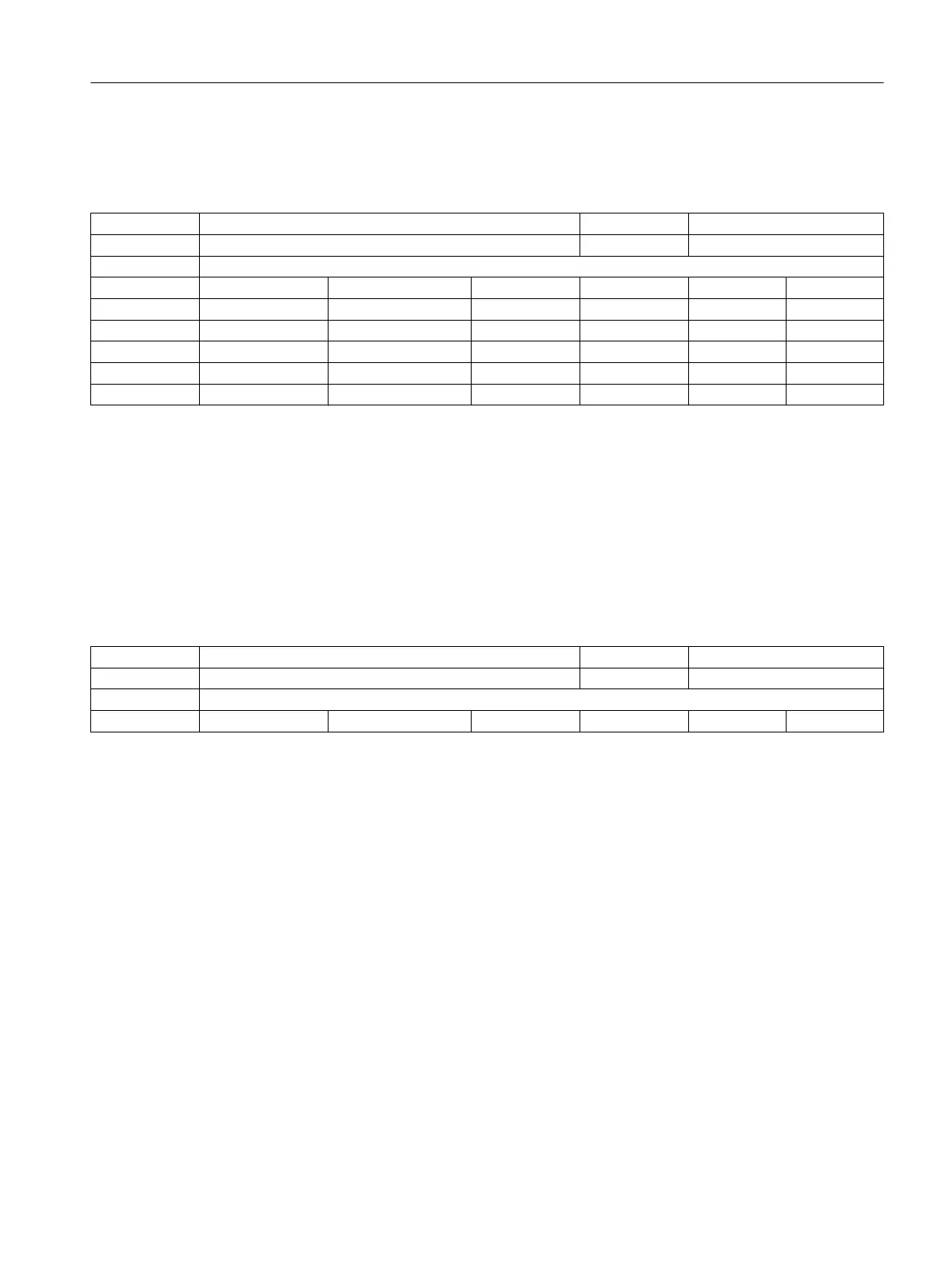

35010 GEAR_STEP_CHANGE_ENABLE A06, A11 P3 pl, P3 sl, S1

- Parameterize gear stage change DWORD Reset

CTEQ

- - 0x00 0 0x2B 2/2

Description: Meaning of bit places:

Bit 0 = 0 and bit 1 = 0:

There is an invariable gear ratio between motor and load. The MD of the first gear

stage is active. Gear stage change is not possible with M40 to M45.

Bit 0 = 1:

Gear stage change at undefined change position. The gear can have up to 5 gear stages,

which

can be

selected with M40, M41 to M45. To support the gear stage change, the motor

can carry out oscillating motions, which must be enabled by the PLC program.

Bit 1 = 1:

Same meaning as bit 0 = 1, although the gear stage change is carried out in a

configured

spindle position

(SW 5.3 and higher). The change position is configured in

MD35012 $MA_GEAR_STEP_CHANGE_POSITION. The position is approached in the current gear

stage before the gear stage change. If this bit is set, bit 0 is not taken into account!

Bit 2: Reserved

Bit 3 = 1:

The gear stage change dialog between NCK and PLC is simulated. The setpoint gear stage

is output to the PLC. A checkback signal from the PLC is not awaited. The

acknowledgment is generated internally in the NCK.

Bit 4: Reserved

Bit 5 = 1:

The second gear stage data set is used for tapping with G331/G332. The bit must be set

for the master spindle used for tapping. Bit 0 or bit 1 must be set.

Machine data

3.4 Axis-specific machine data

Parameter Manual

Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1 267

Loading...

Loading...