For example SD42526 $SC_CORNER_SLOWDOWN_CRIT = 90 means that all corners of 90 degrees

or a more acute angle are traversed slower with G62.

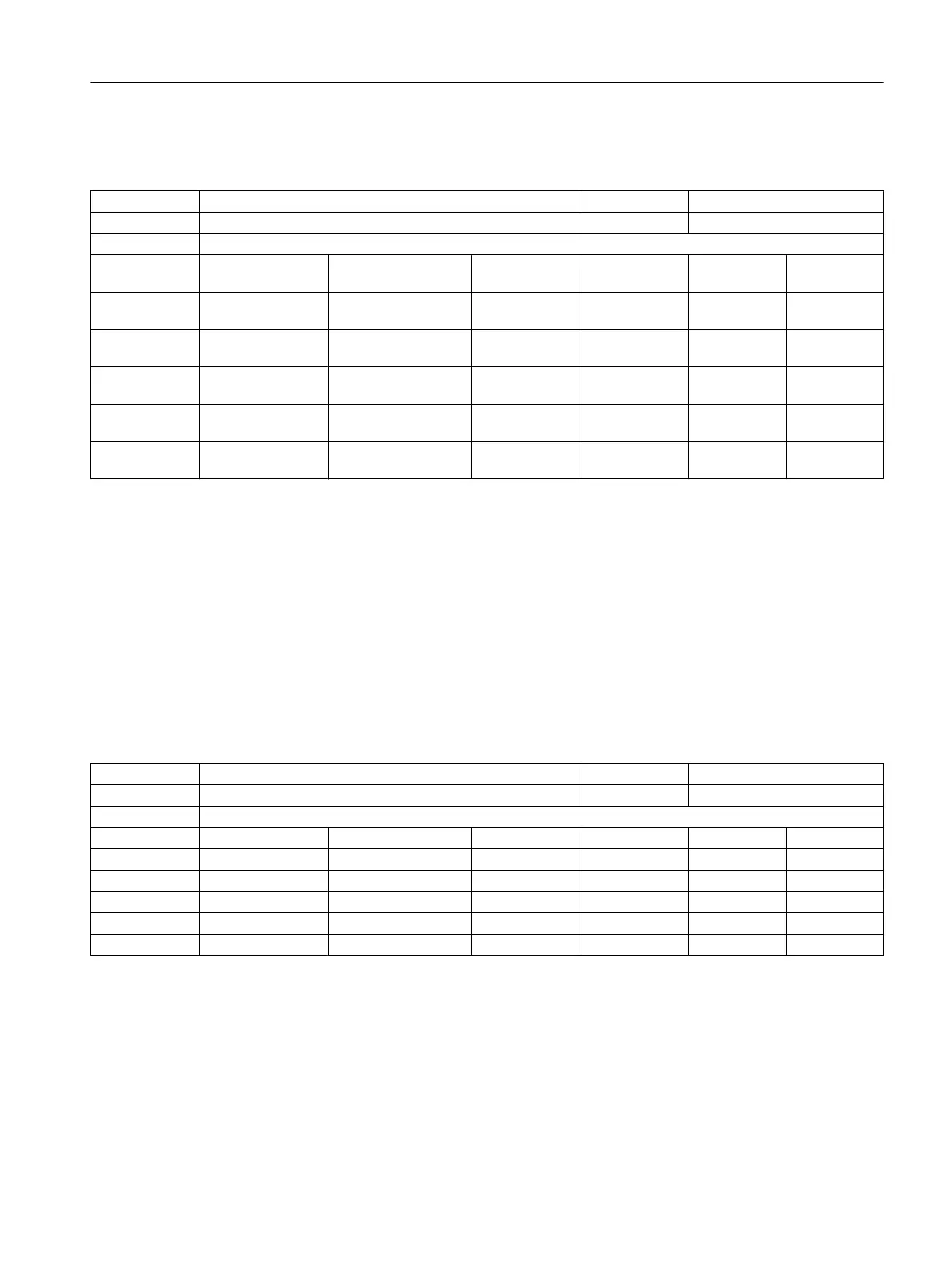

42528 CUTCOM_DECEL_LIMIT - -

- Feed lowering on circles with tool radius compensation DOUBLE Immediately

-

808d-me42 - 0., 0., 0., 0., 0., 0., 0.,

0....

0. 1. 1/1 M

808d-me62 - 0., 0., 0., 0., 0., 0., 0.,

0....

0. 1. 1/1 M

808d-te42 - 0., 0., 0., 0., 0., 0., 0.,

0....

0. 1. 1/1 M

808d-te62 - 0., 0., 0., 0., 0., 0., 0.,

0....

0. 1. 1/1 M

808d-mte40 - 0., 0., 0., 0., 0., 0., 0.,

0....

0. 1. 7/7 U

808d-mte60 - 0., 0., 0., 0., 0., 0., 0.,

0....

0. 1. 7/7 U

Description: The setting data limits feed lowering of the tool center point on concave circle

segments with tool radius compensation active and CFC or CFIN selected.

With CFC, the feed is defined at the contour. On concave circular arcs, feed lowering

of

the tool

center point is created by the ratio of the contour curvature to the tool

center point path curvature. The setting data is limiting this effect, reducing

backing off and overheating of the tool.

For contours with varying curvatures, a mid-range curvature is used.

0: Provides the previous behavior: If the ratio between contour radius and tool

center

point path

radius is less than or equal to 0.01 the feed is applied to the tool

center point path. Less pronounced feed reductions are executed.

>0: Feed lowering is limited to the programmed factor. At 0.01, this means that the

feed of the tool center point path is possibly only 1 percent of the programmed feed

value.

1: On concave contours, the tool center point feed equals the programmed feed (the

behavior then corresponds to CFTCP).

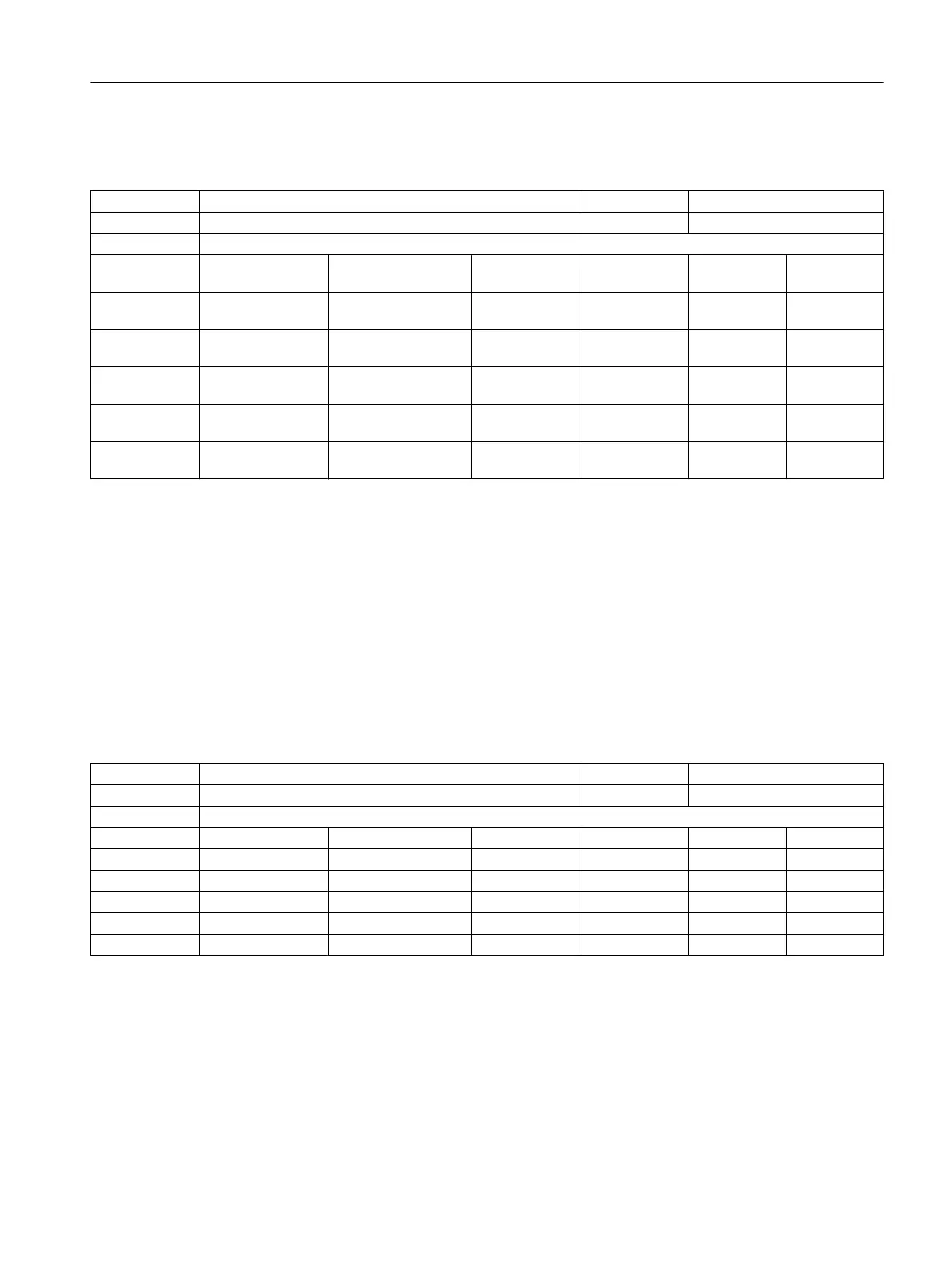

42600 JOG_FEED_PER_REV_SOURCE - V1

- Control revolutional feedrate in JOG DWORD Immediately

-

808d-me42 - 0, 0, 0, 0, 0, 0, 0, 0... -3 31 1/1 M

808d-me62 - 0, 0, 0, 0, 0, 0, 0, 0... -3 31 1/1 M

808d-te42 - 0, 0, 0, 0, 0, 0, 0, 0... -3 31 1/1 M

808d-te62 - 0, 0, 0, 0, 0, 0, 0, 0... -3 31 1/1 M

808d-mte40 - 0, 0, 0, 0, 0, 0, 0, 0... -3 31 7/7 U

808d-mte60 - 0, 0, 0, 0, 0, 0, 0, 0... -3 31 7/7 U

Description: The revolutional feedrate in JOG mode for geometry axes on which a frame with rotation

acts.

0= No revolutional feedrate is active.

>0= Machine axis index of the rotary axis/spindle from which the revolutional

feedrate is derived.

-1= The revolutional feedrate is derived from the master spindle of the channel in

which the axis/spindle is active.

-2= The revolutional feedrate is derived from the axis with machine axis index ==

0.

NC setting data

Parameter Manual

Parameter Manual, 08/2015, 6FC5397-8EP40-0BA1 325

Loading...

Loading...